Method for enzymaticly digesting porcine fat tissue and applications thereof

A pig fat and enzymatic hydrolysis technology, which is applied in the field of super pig fat tissue enzymatic hydrolysis, to achieve the effect of low water content, simple refining method and high edible quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: the preparation method of edible lard

[0078] 1) Grinding: Grinding the pre-frozen pork back fat into mince;

[0079] 2) Enzymolysis: Keep pig back fat at 40°C for 10 minutes at a constant temperature, add neutral protease in an amount of 1200U / g, stir evenly, turn on ultrasonic crushing, ultrasonic power is 540W, ultrasonic frequency is 20kHz, and the ultrasonic process lasts for a total time During the ultrasonic process, the ultrasonic time and the intermittent time are 5s and 5s respectively, and the ultrasonic and intermittent are carried out alternately. After the ultrasonic, continue to stir at 90r / min, and control the temperature to 40°C, and adjust it with 1mol / L sodium hydroxide The pH is 7.0-7.2, and the total enzymolysis time from the addition of neutral protease to the end of the final enzymolysis is 90 minutes.

[0080] 3) Centrifugation: centrifuge after the enzymolysis is completed, the centrifugation conditions are: centrifugation temper...

experiment example 1

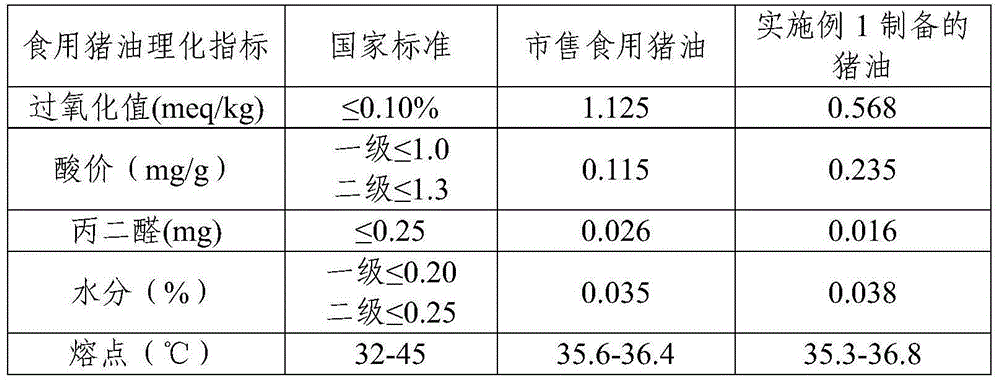

[0083] According to the national standard, the part physicochemical characteristics of the high-grade edible lard obtained by this method are compared with the commercially available edible lard, and the results are shown in Table 1.

[0084] Table 1 is the part physical and chemical index that obtains edible lard in embodiment 1

[0085]

[0086] Table 1 result shows: the lard yield rate that embodiment 1 obtains is 91-94%, has the high rate of fat, and crude oil flavor is good, good quality, refining method is simple, and product oxidation stability is good, and commercially available edible lard In comparison, the physical and chemical indicators are better.

experiment example 2

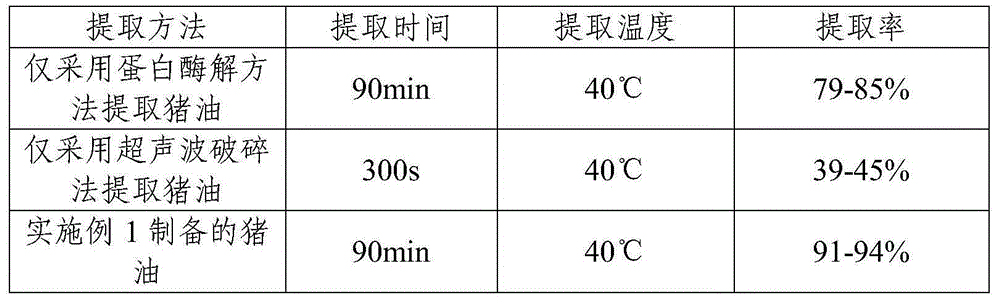

[0088] In order to illustrate the effect of ultrasonic-assisted enzymatic hydrolysis on the efficiency of lard extraction, a comparative experiment was carried out, and the results are shown in Table 2.

[0089] Table 2 is the comparison of the extraction effects of the different methods of extracting lard in Example 1

[0090]

[0091] The results in Table 2 show that the lard provided by Example 1 has an extraction rate as high as more than 90%.

[0092] The results show that the extraction rate of the method for preparing lard provided by the invention is higher than that of the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com