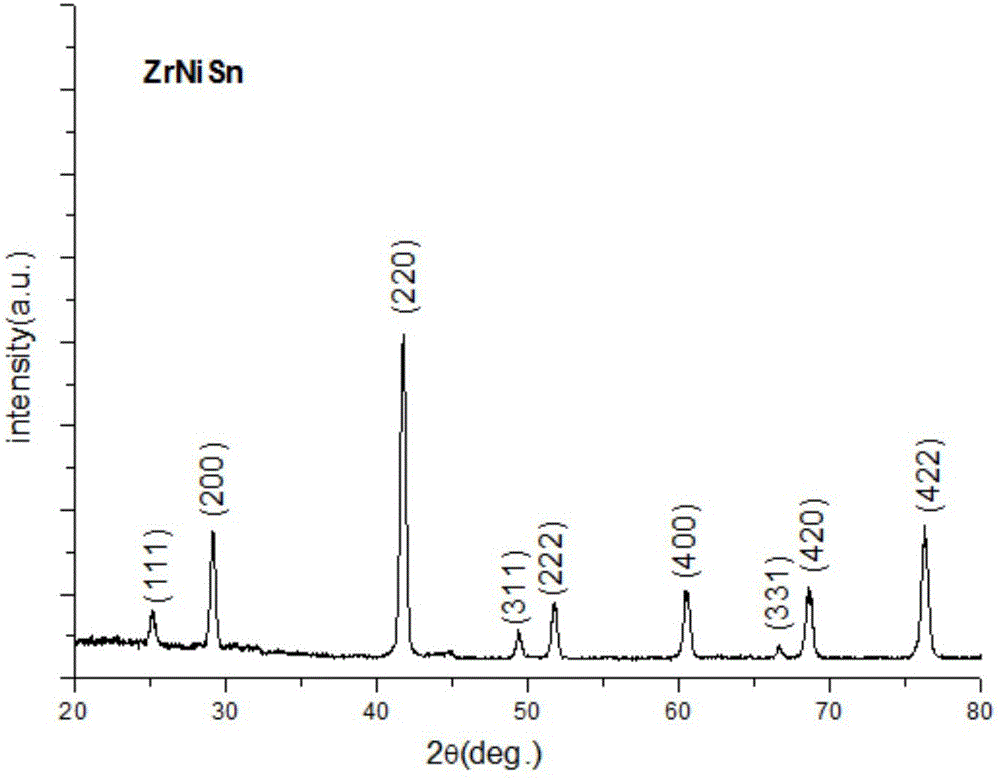

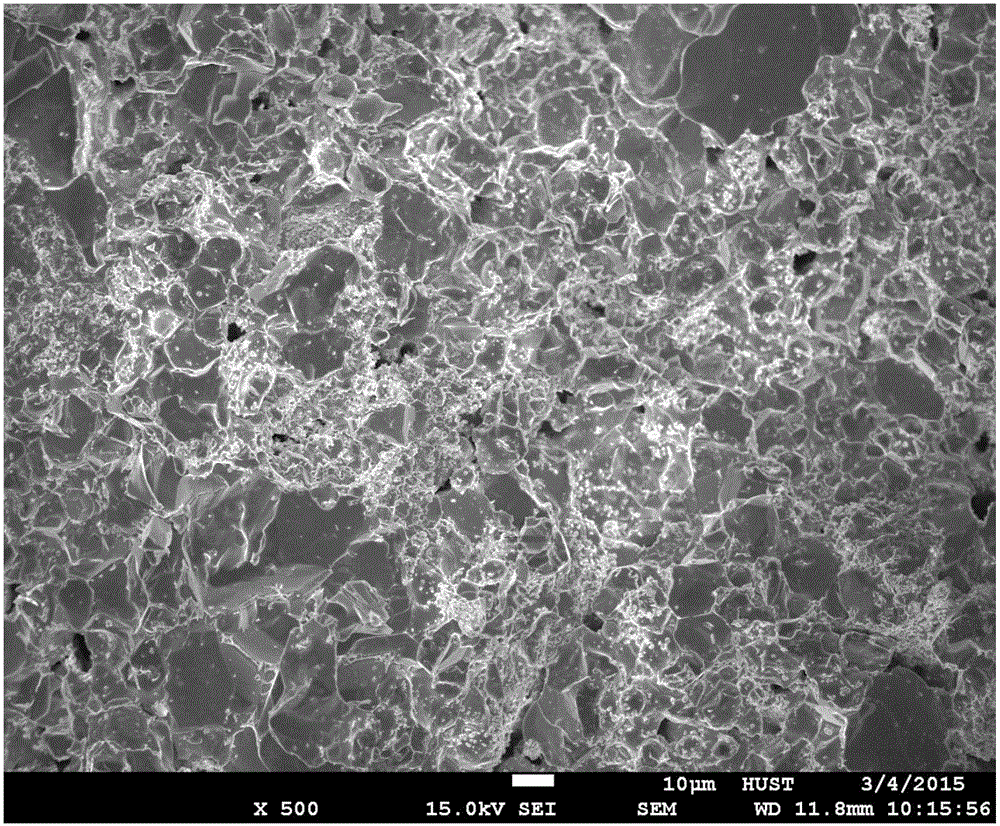

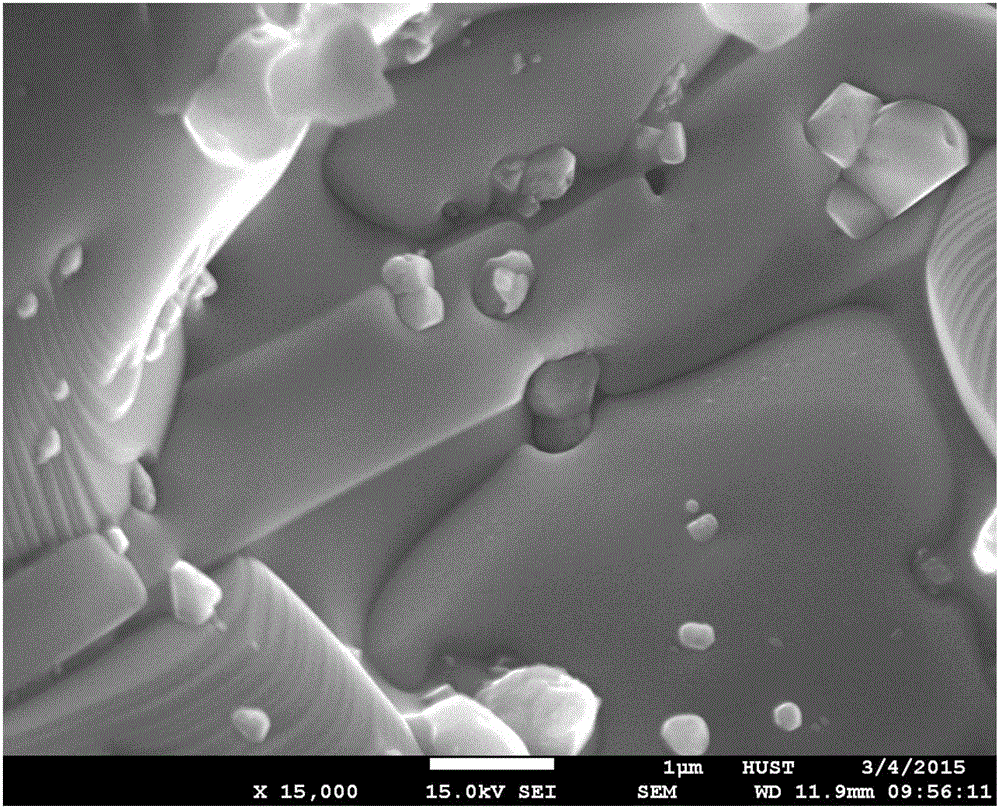

Quick microwave synthesizing-sintering preparation method of ZrNiSn bulk thermoelectric material

A thermoelectric material and microwave synthesis technology, which is applied in the field of microwave rapid synthesis-sintering to prepare ZrNiSn bulk thermoelectric materials, can solve the problems of high equipment cost, slow heating rate and high cost, and achieves synthesis efficiency and quality improvement, density and uniformity. The effect of improving property and thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a ZrNiSn bulk thermoelectric material by microwave rapid synthesis-sintering in this embodiment, the steps are:

[0038] Step 1. Raw material preparation and cold pressing molding:

[0039] Using Zr, Ni, and Sn metal elemental powders with mass fractions not less than 99.99% as raw materials, weigh the above three metal elemental powders according to the stoichiometric molar ratio of 1:1:1, a total of 3.5g; The metal elemental powders were mixed to form a mixed powder, and the mixed powder was placed in an agate mortar and acetone was added for manual grinding for 20 minutes, so that the three metal elemental powders could be fully mixed evenly. After the acetone is completely volatilized, put the uniformly mixed powder into a cold-press mold, and perform cold-press molding under the action of an electric tablet press to form a cold-press block, and the cold-press pressure is 20 MPa.

[0040] Step 2, microwave synthesis:

[0041] Place the cold-...

Embodiment 2

[0048] A method for preparing a ZrNiSn bulk thermoelectric material by microwave rapid synthesis-sintering in this embodiment, the steps are:

[0049] Step 1. Raw material preparation and cold pressing molding:

[0050] Using Zr, Ni, and Sn metal elemental powders with mass fractions not less than 99.99% as raw materials, weigh the above three metal elemental powders according to the stoichiometric molar ratio of 1:1:1, a total of 3.8g; The metal elemental powders were mixed to form a mixed powder, and the mixed powder was placed in an agate mortar and acetone was added for manual grinding for 30 minutes, so that the three metal elemental powders could be fully mixed and ground. After the acetone is completely volatilized, put the uniformly mixed powder into a cold-press mold, and perform cold-press molding under the action of an electric tablet press to form a cold-press block, and the cold-press pressure is 30 MPa.

[0051] Step 2, microwave synthesis:

[0052] Place the c...

Embodiment 3

[0058] A method for preparing a ZrNiSn bulk thermoelectric material by microwave rapid synthesis-sintering in this embodiment, the steps are:

[0059] Step 1. Raw material preparation and cold pressing molding:

[0060] Using Zr, Ni, and Sn metal elemental powders with mass fractions not less than 99.99% as raw materials, weigh the above three metal elemental powders according to the stoichiometric molar ratio of 1:1:1, a total of 4.5g; The metal elemental powders were mixed to form a mixed powder, and the mixed powder was placed in an agate mortar and acetone was added for manual grinding for 10 minutes, so that the three metal elemental powders could be fully mixed and ground. After the acetone is completely volatilized, put the uniformly mixed powder into a cold-press mold, and perform cold-press molding under the action of an electric tablet press to form a cold-press block, and the cold-press pressure is 100 MPa.

[0061] Step 2, microwave synthesis:

[0062] Place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com