A kind of method of deep drying lithium ion battery powder material

A technology for lithium-ion batteries and powder materials, which is applied in the direction of drying solid materials, drying solid materials, drying chambers/containers, etc. by combining methods, and can solve the problems of long cooling cycle of hot oil, complicated switching of hot and cold oil, and no protection measures, etc. problems, to achieve rapid and uniform heating and cooling, easy industrial application, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

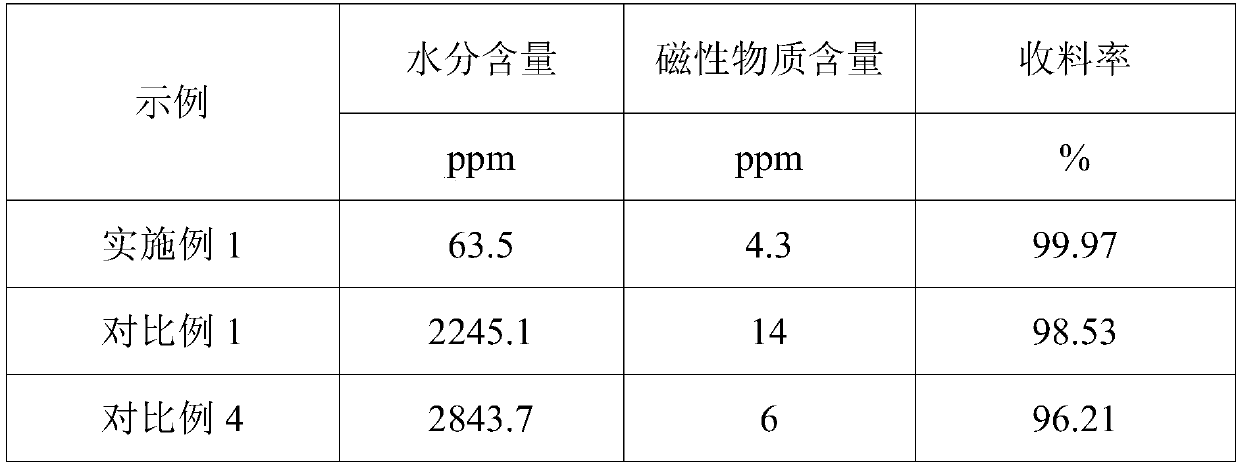

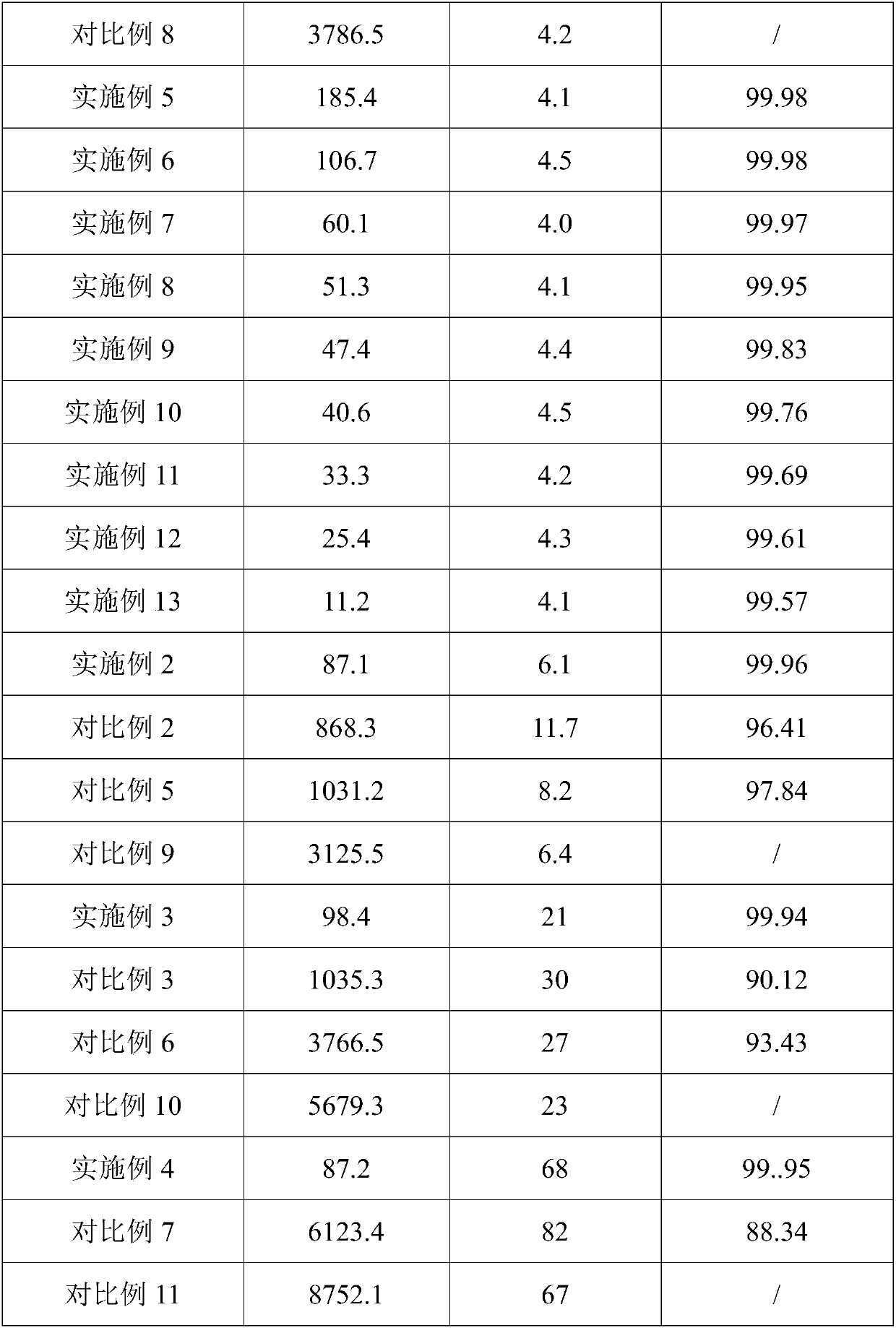

Embodiment 1

[0063] 25 kg of LiNi with a median diameter of 11 μm 0.8 co 0.15 al 0.05 o 2 The powder material is encapsulated in a polytetrafluoroethylene microporous tank. The average pore size of the microporous tank is 6 μm. When the temperature reaches 110°C, stop the ventilation, start the heating rod again, keep the temperature at 110°C for 1 hour, then gradually raise the temperature to 180°C and keep the temperature, keep vacuuming until the vacuum degree is stable at 80Pa, turn off the heating after drying for 10 hours, and continue to pass in normal temperature decarburization dry air To cool the material, after the drying oven is reduced to normal pressure, the material is transferred to a drying room with a dew point of -40°C connected in series with the drying oven, and the material is taken out and packaged in an aluminum-plastic film bag to obtain the corresponding positive electrode material.

Embodiment 2

[0065] 10 kg of LiFePO with a median diameter of 3 μm 4 / C The powder material is packed in 5kg / bag in a polypropylene composite microporous bag of 20×30cm. The average micropore size of the microporous bag is 1 μm. The bag is placed in a microwave vacuum drying oven and preheated to Dry N at 105°C 2 When the temperature of the material reaches 100°C, stop the ventilation, heat the powder material with a microwave with a power of 2kW and a frequency of 2450Hz, and continue vacuuming until the vacuum degree is stable at 50Pa. 2 To cool the material, after the drying furnace is reduced to normal pressure, the material is transferred to the drying furnace connected in series with the drying furnace. 2 In a simple plexiglass glove box with a dew point of -50°C, open the bag and take out the material and package it in an aluminum-plastic film bag to obtain a powder material with a correspondingly low moisture content.

Embodiment 3

[0067] The median diameter of 5kg is 20μm, and the specific surface area is 700m 2 The porous carbon additive per gram is placed in a macroporous stainless steel chamber with a polyimide microporous membrane as the inner coating. The average micropore size of the microporous membrane is 10 μm. Put the chamber into a vacuum drying kettle and pass into dry N preheated to 118°C 2 When the temperature of the material reaches 110°C, the ventilation is stopped, and the jacket is heated by heating oil, and the vacuum is continuously evacuated until the vacuum degree is stable at 50Pa. After drying for 8 hours, the heating device is turned off, and the dry air at normal temperature is continuously introduced to cool the material, and the drying kettle is lowered to After normal pressure, transfer the material to a glove box connected in series that is full of air and has a water content below 1ppm. Open the bag, take out the material and seal it in an aluminum-plastic film bag to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com