Method for measuring contents of bismuth and lead ions in tin lead bismuth alloy electroplating solution

A measurement method and alloy electroplating technology, which is applied in the preparation of test samples, measurement of color/spectral characteristics, material analysis through observation of the influence of chemical indicators, etc., can solve the problems of bismuth and lead ion content, complex composition, etc. problems, to achieve the effect of convenient detection process, accurate detection results and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the mensuration of bismuth content

[0023] 1. Preparation of blank solution

[0024] a. Draw 5.00mL of the electroplating solution to be tested and place it in a 50mL volumetric flask;

[0025] b. Add 4mL of nitric acid solution (1+1), 10mL of tartaric acid solution with a concentration of 100g / L, and 5mL of ascorbic acid solution with a concentration of 100g / L into a 50mL volumetric flask;

[0026] c. Add water to dilute to the mark, shake well and set aside;

[0027] 2. Draw the working curve

[0028] a. Add 0.00mL, 0.50mL, 1.00mL, 1.50mL, 2.00mL and 2.50mL of bismuth standard solution with a concentration of 0.5mg / mL into six 50mL volumetric flasks respectively;

[0029] b. Add 4mL nitric acid solution (1+1), 10mL tartaric acid solution with a concentration of 100g / L and 10.00mL thiourea solution with a concentration of 50g / L in turn into 6 volumetric flasks;

[0030] c. Add water to dilute to the mark and shake well;

[0031] D, at the 465nm wave...

Embodiment 2

[0040] Embodiment 2: the mensuration of lead content

[0041] 1. Draw 20.00mL of the electroplating solution to be tested and place it in a 250mL conical flask;

[0042] 2. Add 1mL hydrogen peroxide (30%), 10.00mL EDTA-2Na standard solution with a concentration of 0.05mol / L, 50mL water, and 2g ammonium fluoride into a 250mL Erlenmeyer flask in sequence, and shake well;

[0043] 3. Add 30mL of hexamethylenetetramine solution with a concentration of 300g / L to adjust the pH value of the solution in the Erlenmeyer flask to 5-6;

[0044] 4. Add 3 drops of xylenol orange indicator solution with a concentration of 5g / L in the Erlenmeyer flask, and titrate with a zinc standard titration solution with a concentration of 0.03mol / L until the solution turns red and does not fade in 30s as the end point;

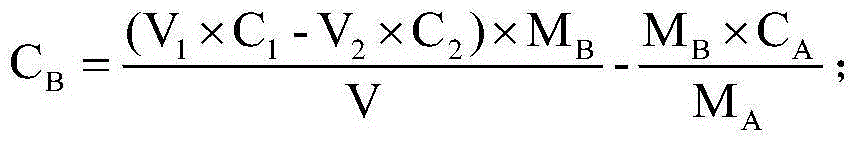

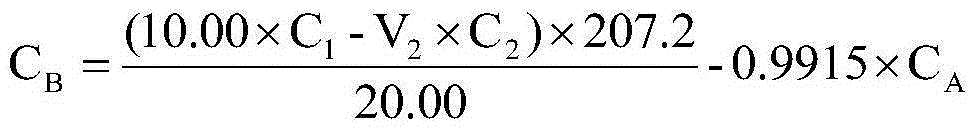

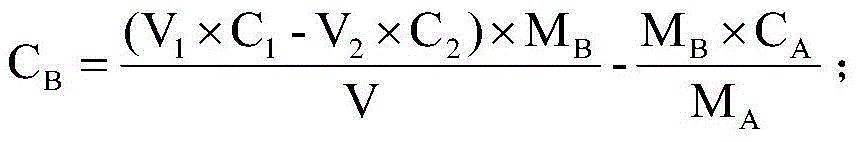

[0045] 5. Calculation of lead content

[0046] The lead content is calculated according to the following formula:

[0047] C B = ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com