Processing method of flammulina velutipes mushroom root powder with improved color and luster

A technology for the mushroom root and processing method of Flammulina velutipes, which is applied in food processing, food science, food preservation and other directions, can solve the problems such as yellowing of the enoki mushroom, low heat energy utilization, burnt smell, etc., so as to avoid oxidative browning and prolong the Preservation time, the effect of strong fungus fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A processing method for improving color and luster of Flammulina velutipes root powder, comprising steps as follows:

[0028] (1) The fresh Flammulina velutipes mushroom root of factory production is directly excised culture medium, removes impurity, rejects diseased root, rotten root and the mushroom root of pollution, obtains the raw material of processing mushroom root powder, and described fresh mushroom root water content is 85% ;

[0029] (2) Superheated steam drying: use superheated steam to dry for 2 hours, dry the fresh mushroom roots until the water content of the material is 30%, the steam pressure of the superheated steam is 120.05kPa, the steam temperature is 140°C, and the steam flow rate is 3.0m / s;

[0030] (3) Drying under reduced pressure and dehumidification: place the material dried by superheated steam under a vacuum degree of -0.2Mpa, and carry out dehumidification and drying for 0.5h, so that the water content of Flammulina velutipes is 7%, and the...

Embodiment 2

[0033] A processing method for improving color and luster of Flammulina velutipes root powder, comprising steps as follows:

[0034] (1) The fresh Flammulina velutipes mushroom root of factory production is directly excised culture medium, removes impurity, rejects diseased root, rotten root and polluted mushroom root, obtains the raw material of processing mushroom root powder, and described fresh mushroom root water content is 82% ;

[0035] (2) Superheated steam drying: use superheated steam to dry for 3 hours, dry the fresh mushroom roots until the water content of the material is 25%, the steam pressure of the superheated steam is 140.50kPa, the steam temperature is 160°C, and the steam flow rate is 4.0m / s;

[0036] (3) Drying under reduced pressure and dehumidification: place the material dried by superheated steam under a vacuum degree of -0.15Mpa, and carry out dehumidification and drying for 1 hour, so that the water content of Flammulina velutipes is 5%, and the temp...

experiment example

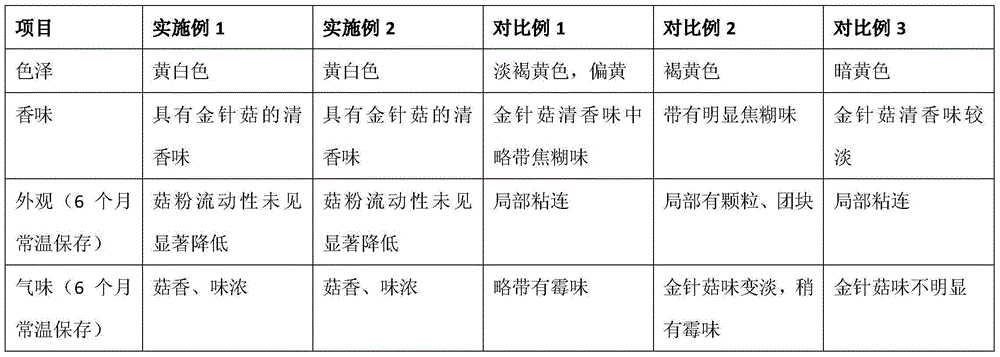

[0048] 1. Quality evaluation of Flammulina velutipes root powder

[0049] The prepared Flammulina velutipes root powder of Examples 1-2 and Comparative Example 11-3 were stored in a dry and cool place at room temperature for 6 months to observe the stability of the product, the results are shown in Table 1 below.

[0050] Table 1

[0051]

[0052] After observing the appearance quality of the product, it can be found that the root of Flammulina velutipes obtained by the treatment of Examples 1-2 is yellowish-white in color and has a strong bacterial fragrance. After a period of time, the fluidity of the mushroom powder has not been significantly reduced. The color of Flammulina velutipes mushroom root powder prepared by steam combined with decompression and dehumidification and drying is yellowish, brownish yellow, dark yellow or even browning, and has a slightly burnt smell. After a period of time, the fluidity of the mushroom powder becomes significantly worse. The proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com