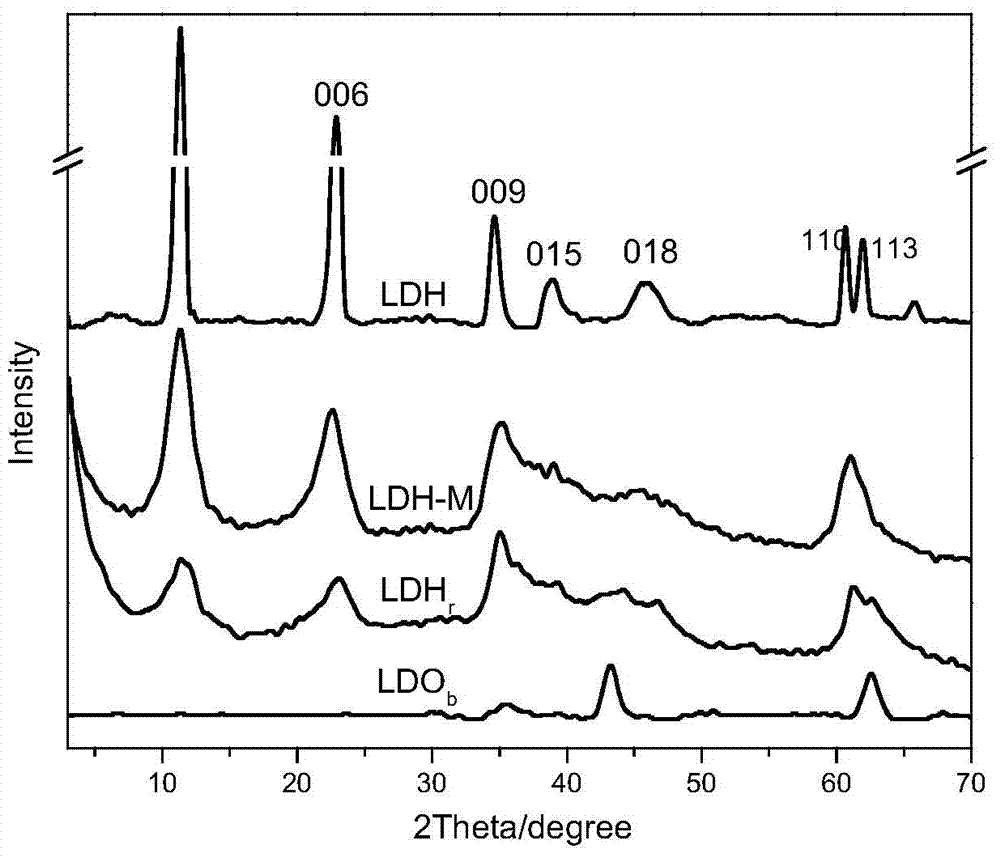

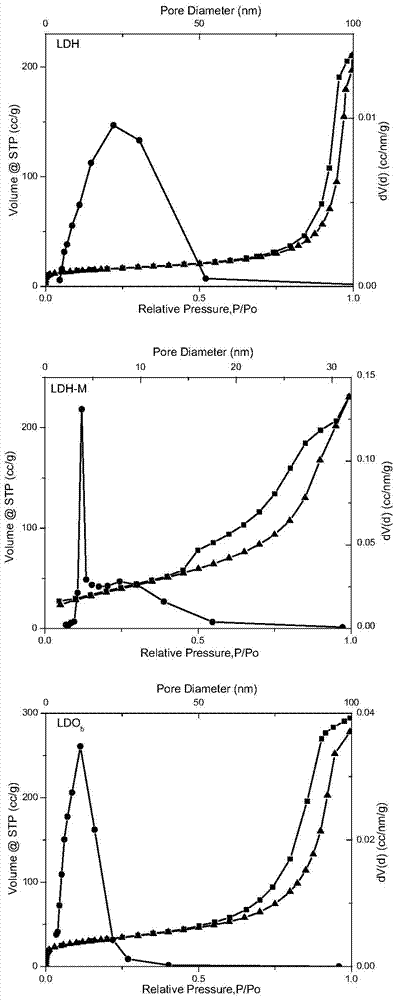

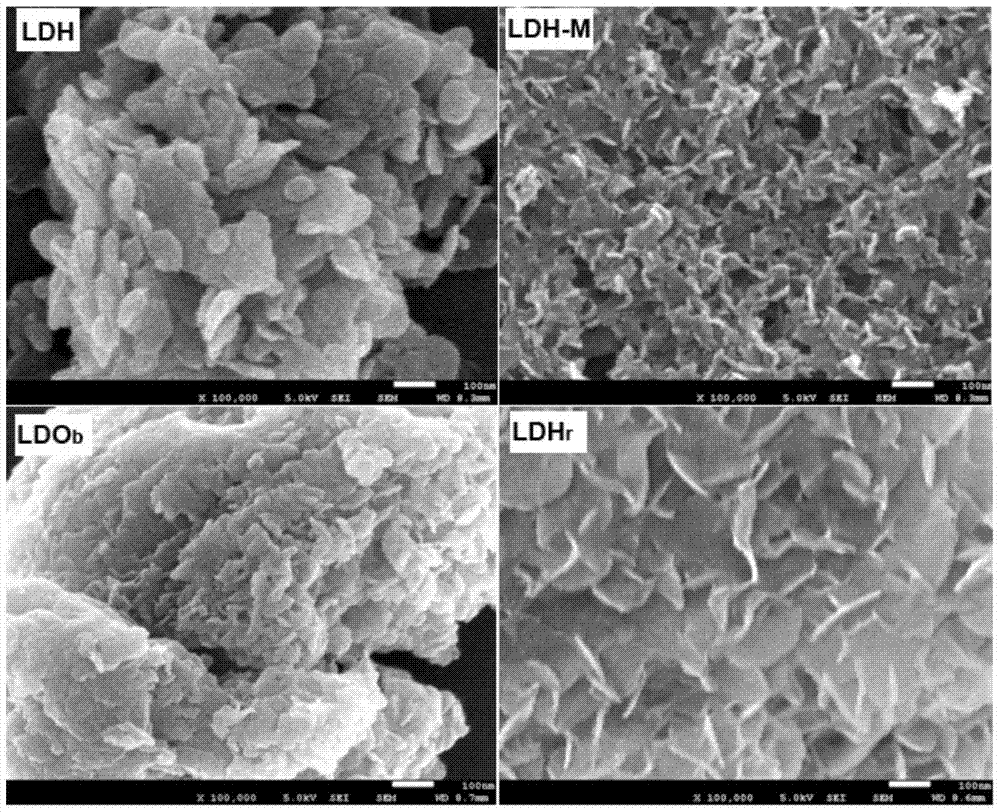

A preparation method of layered double metal oxide adsorbent for effectively removing low-concentration phosphate

A layered bimetal and oxide technology, applied in the field of nanomaterials, achieves the effects of small pore volume, mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Weigh MgCl respectively 2 ·6H 2 O and AlCl 3 9H 2 O, add deionized water to prepare a total metal ion concentration of 0.45mol / L, MgCl 2 and AlCl 3 The molar concentration ratio is 2:1; N,N-dimethylformamide (DMF) and hydrophobic ionic liquid BmimPF are added to the mixed salt solution 6 , where mixed saline solution, DMF and BmimPF 6 The volume ratio of the solution was 4:48:48, stirred magnetically at room temperature for 40 minutes, and the inverse microemulsion A was prepared after the solution changed from turbid to transparent;

[0033] 2) Take a certain volume concentration of 25% ammonia water, add DMF and BmimPF to it 6 , make 25% ammonia water, DMF and BmimPF 6 The volume ratio of the solution was 4:48:48, magnetically stirred at room temperature for 40 minutes, and the inverse microemulsion B was prepared after the solution changed from turbid to transparent;

[0034] 3) Under the condition of magnetic stirring, titrate the inverse microemulsion A ...

Embodiment 2

[0037] 1) With reference to the method and preparation conditions in Example 1 step 1), only change the mixed salt solution, DMF and BmimPF 6 The volume ratio is 7:46.5:46.5, and the inverse microemulsion A is prepared;

[0038] 2) With reference to the method and preparation conditions in Example 1 step 2), only change the mixed salt solution, DMF and BmimPF 6 The volume ratio of is 7:46.5:46.5, and the inverse microemulsion B is prepared;

[0039] 3) Using the method and preparation conditions in step 3) of Example 1, the precursor small particle size ultra-thin hydrotalcite-like nanosheets are obtained;

[0040] 4) Using the method and preparation conditions in Step 4) of Example 1, calcining the precursor small particle size ultra-thin hydrotalcite-like nanosheets obtained in the previous step to obtain a layered double metal oxide adsorbent, denoted as LDO b .

Embodiment 3

[0042] 1) With reference to the method and preparation conditions in Example 1 step 1), only change the mixed salt solution, DMF and BmimPF 6 The volume ratio of is 7:31:62, and the inverse microemulsion A is prepared;

[0043] 2) With reference to the method and preparation conditions in Example 1 step 2), only change the mixed salt solution, DMF and BmimPF 6 The volume ratio of is 7:31:62, and the inverse microemulsion B is prepared;

[0044] 3) Using the method and preparation conditions in step 3) of Example 1, the precursor small particle size ultra-thin hydrotalcite-like nanosheets are obtained;

[0045] 4) Using the method and preparation conditions in Step 4) of Example 1, calcining the precursor small particle size ultra-thin hydrotalcite-like nanosheets obtained in the previous step to obtain a layered double metal oxide adsorbent, denoted as LDO c .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com