Sludge low-temperature waste heat drier

A low-temperature waste heat, drying machine technology, applied in the direction of dehydration/drying/concentrating sludge treatment, etc., can solve the problems of large maintenance, reduce oxygen content, complex drying process, etc., achieve long service life, inhibit volatilization, The effect of fewer wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

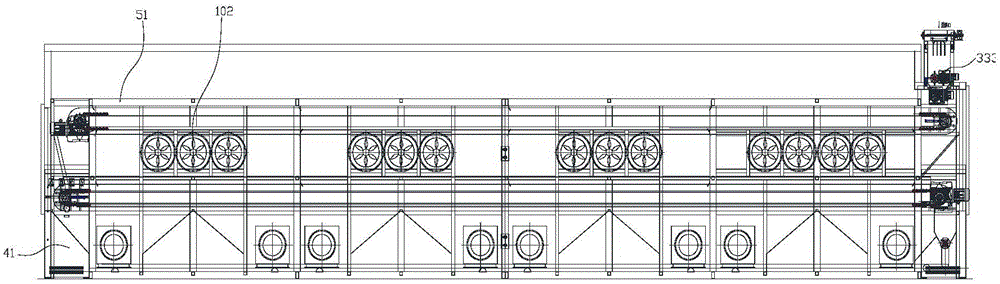

[0037] Sludge low temperature waste heat drying machine, such as figure 1 with Figure 5 As shown, it includes several low-temperature waste heat drying units. According to the needs, several low-temperature waste heat drying units are spliced together to form an overall production line. This is flexible assembly, and the corresponding number of units can be selected according to needs, which is convenient for future expansion and easy transportation.

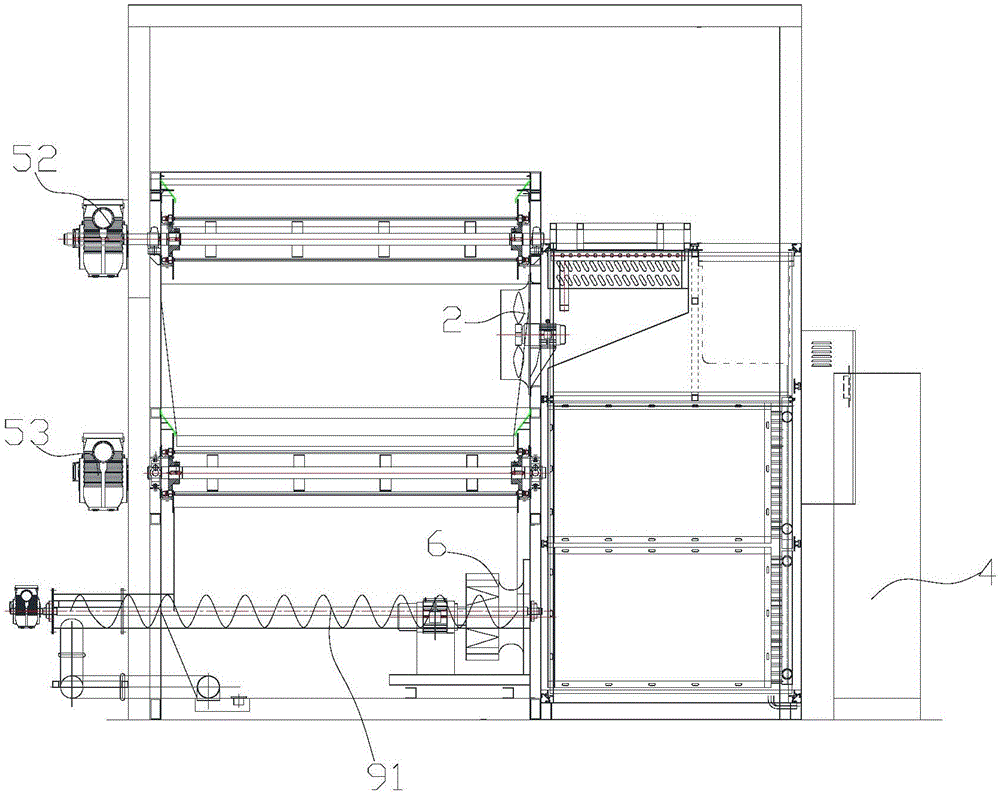

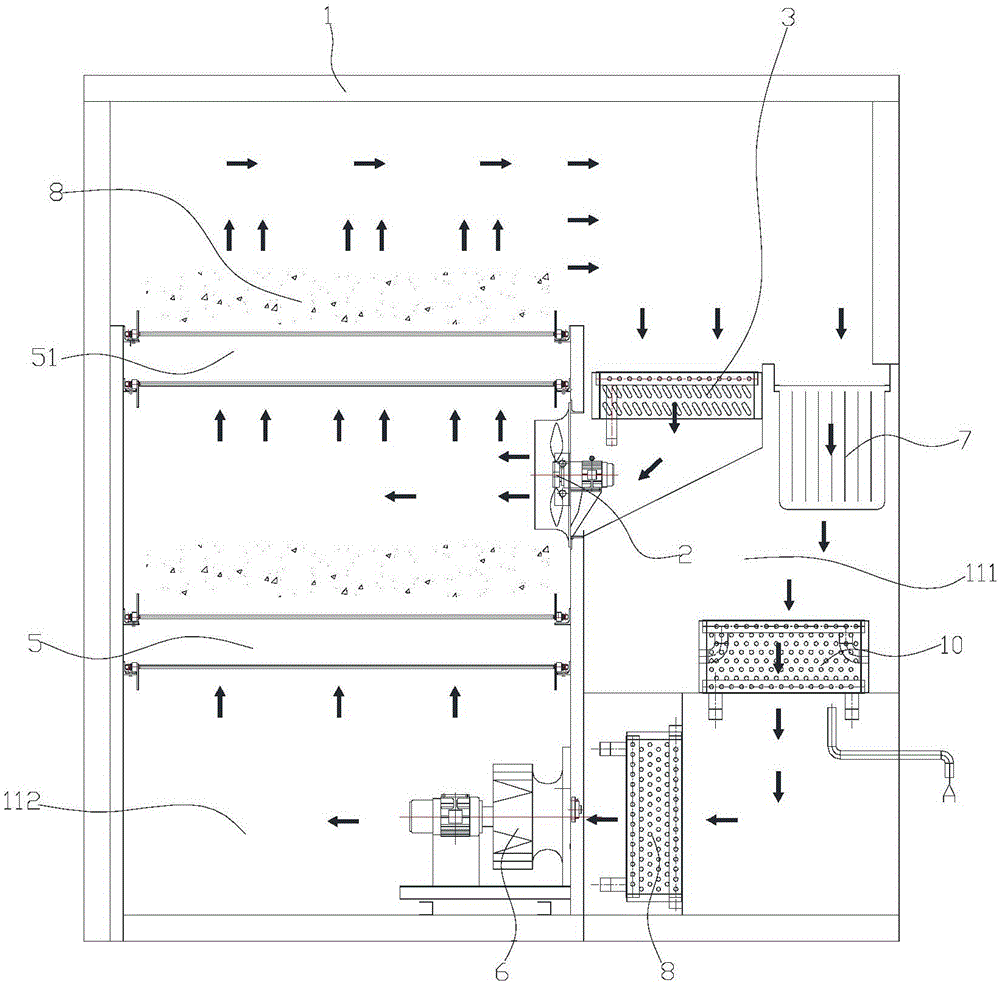

[0038] The low-temperature waste heat drying unit is as Figure 2-4 As shown, it includes a frame 1, the frame 1 is provided with a drying area 112 and a functional area 111, and a baffle is arranged between the drying area 112 and the functional area 11, and between the drying area 112 and the functional area 111 A blower fan 6 and an air return port arranged at the upper end are arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com