Method for preparing novel antibacterial electronic cigarette appearance material

An electronic cigarette, a new technology, applied in the field of electronic cigarette materials, can solve the problem of few applications, and achieve the effect of simple raw materials, wide market application prospects, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

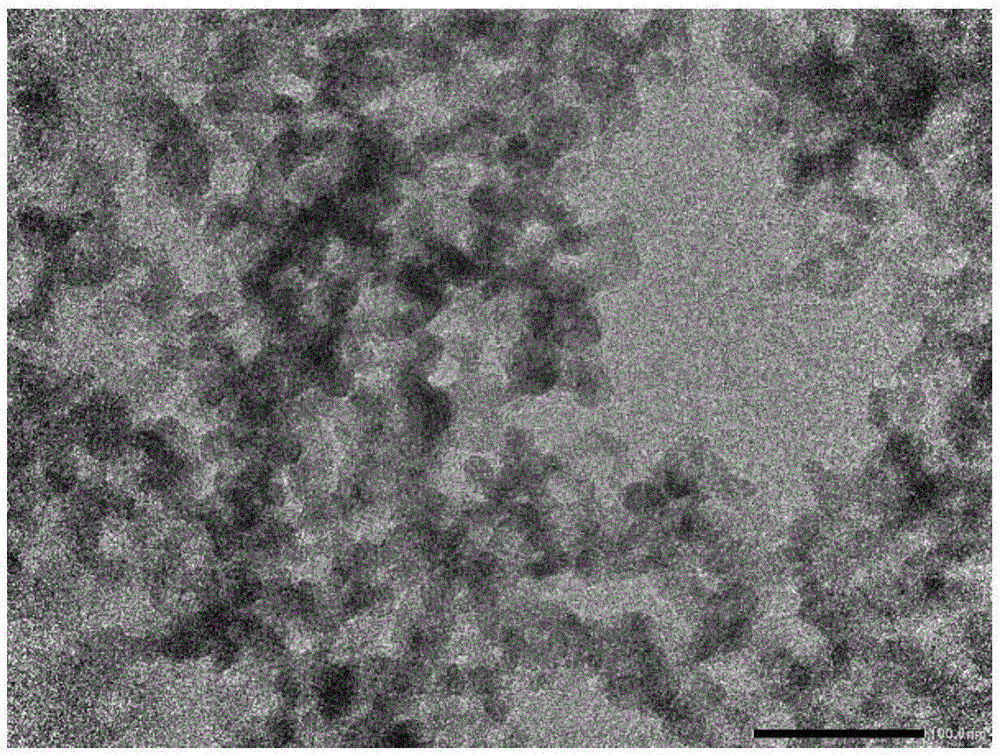

Image

Examples

Embodiment 1

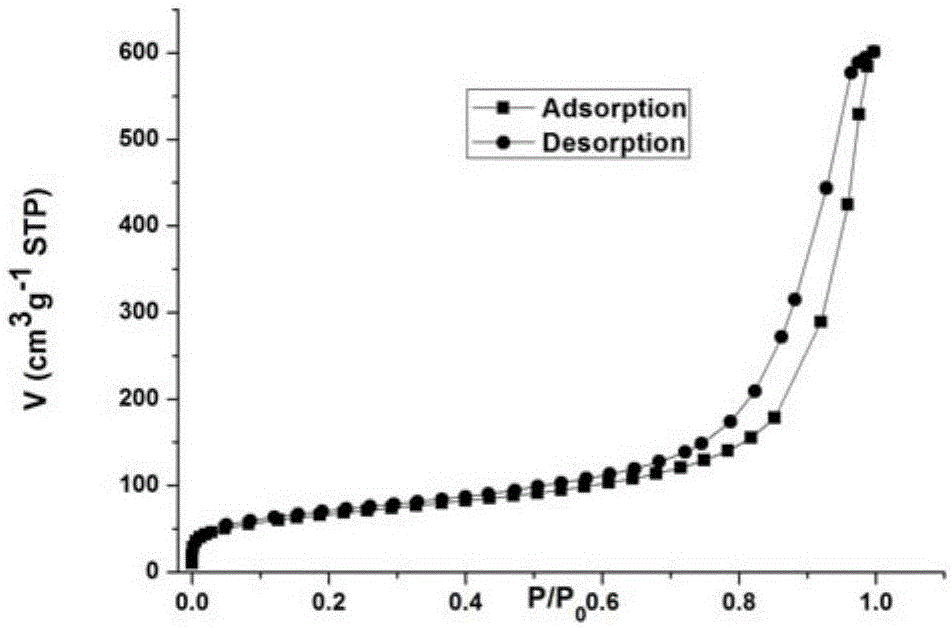

[0031] Embodiment 1: 1.016g tetrapropyl ammonium hydroxide (TPAOH) and 0.082g sodium metasilicate (NaAlO 2 ) was stirred and dissolved in 12mL of water, 1.065g of tetrapropylammonium bromide (TPABr) was dissolved in 6mL of water, the two solutions were mixed, and after stirring at room temperature for 10 to 50 minutes, a uniform solution was obtained, and tetraethyl orthosilicate (TEOS ) 4.792 g was stirred overnight at room temperature. The resulting mixture was continuously stirred and heated at 250 rpm in an oil bath at 140°C for 12 hours, washed with water and ethanol for more than two times after centrifugation, and dried at 70°C to obtain the target nano-zeolite material. The obtained nano-zeolite was calcined in vacuum at 200°C for 5 hours, and dispersed in 0.01M silver nitrate (AgNO 3 ) aqueous solution 50mL, and stirred in the dark for 12h, the product was washed with deionized water, and dried to obtain a silver-loaded nano-zeolite material. 500 mg of the obtained ...

Embodiment 2

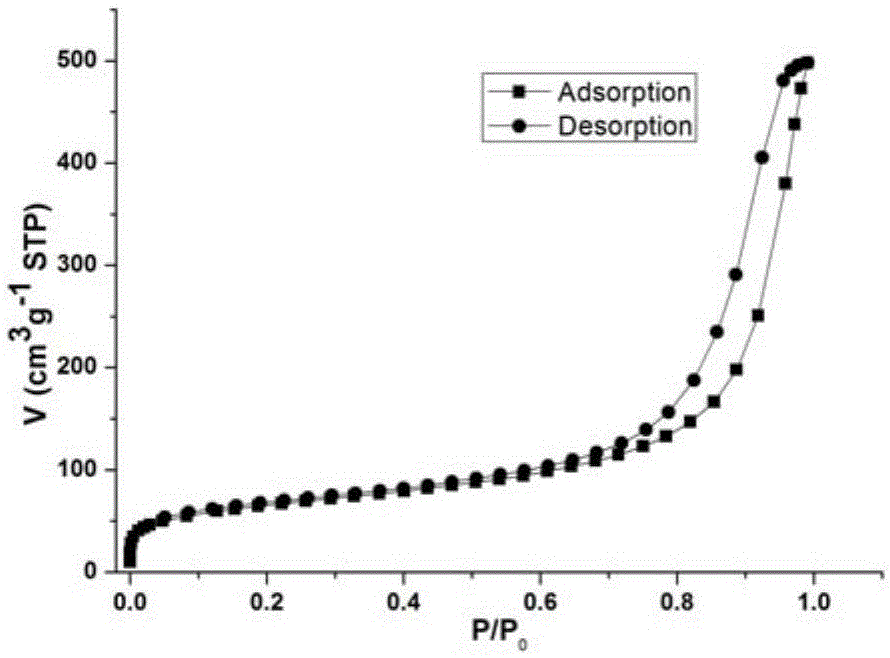

[0032] Embodiment 2: 1.531g tetrapropyl ammonium hydroxide (TPAOH) and 0.083g sodium metasilicate (NaAlO 2 ) was stirred and dissolved in 18 mL of water, and after stirring at room temperature for 10 to 50 minutes, a uniform mixed solution was obtained, and 5.125 g of tetraethyl orthosilicate (TEOS) was added and stirred overnight at room temperature. The resulting mixture was continuously stirred and heated at 250 rpm in an oil bath at 140°C for 72 hours, washed with water and ethanol for more than two times after centrifugation, and dried at 70°C to obtain the target nano-zeolite material. The steps of nano-zeolite silver loading, organicization, and plastic melt blending to prepare composite materials are the same as in Example 1.

Embodiment 3

[0033] Embodiment 3: 1.039g tetrapropyl ammonium hydroxide (TPAOH) and 0.078g sodium metasilicate (NaAlO 2 ) was stirred and dissolved in 18mL of water, and 0.089g of tetrapropylammonium bromide (TPABr) was added. After stirring at room temperature for 10 to 50 minutes, a uniform mixed solution was obtained, and 4.167g of tetraethyl orthosilicate (TEOS) was added and stirred at room temperature. overnight. The resulting mixture was continuously stirred and heated at 400 rpm in an oil bath at 140°C for 24 hours, washed with water and ethanol for more than two times after centrifugation, and dried at 70°C to obtain the target nano-zeolite material. The steps of nano-zeolite silver loading, organicization, and plastic melt blending to prepare composite materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com