A self-healing electric heating coating for interior walls of buildings

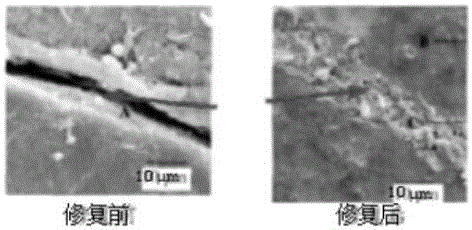

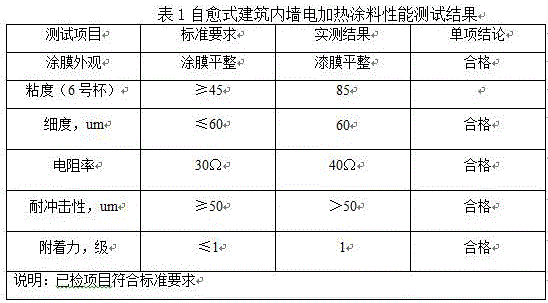

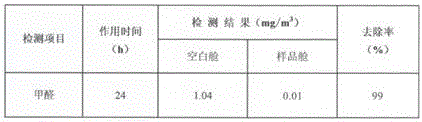

An in-building, electric heating technology, applied in the field of building materials, can solve problems such as restricting the wide application of electric heating coatings, coating scratches or cracks, damage to indoor aesthetics, etc., and achieves high mechanical strength, long service life, and uniform heated coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A self-healing electric heating paint for building interior walls. The self-healing electric heating paint for building interior walls includes the following components: 10-parts of acrylic resin, 4 parts of propylene oxide, 1.5 parts of chitosan, 15 parts of graphite powder, nano 0.5 parts of silicon dioxide, 2 parts of activated carbon acrylic fiber, 0.5 parts of acetic anhydride, 1 part of diatomaceous earth, 1 part of pigment, 2 parts of mica powder, 1 part of adhesion promoter, 1 part of dispersant, 0.1 part of flame retardant share.

[0023] Wherein, the bioactive enzyme formed by citric acid-modified soybean protein is solidified on the activated carbon acrylic fiber, and the propylene oxide is a cyclic molecule propylene oxide, and the chitosan is the propylene oxide in shrimp and crab shells. The extracted chitosan, the dispersant is one of polycarboxylate sodium salt type copolymer, oxygen-containing copolymer, polymethacrylate or its mixture, and the flame re...

Embodiment 2

[0025] A self-healing electric heating paint for interior walls of buildings, said self-healing electric heating paint for interior walls of buildings comprises the following components: 20 parts of acrylic resin, 6 parts of propylene oxide, 3 parts of chitosan, and 20 parts of graphite powder , 1.5 parts of nano-silica, 3 parts of activated carbon acrylic fiber, 1 part of acetic anhydride, 6 parts of diatomaceous earth, 3 parts of pigment, 4 parts of mica powder, 2 parts of adhesion promoter, 5 parts of dispersant, flame retardant 1 dose.

[0026] Wherein, the bioactive enzyme formed by citric acid-modified soybean protein is solidified on the activated carbon acrylic fiber, and the propylene oxide is a cyclic molecule propylene oxide, and the chitosan is the propylene oxide in shrimp and crab shells. The extracted chitosan, the dispersant is one of polycarboxylate sodium salt type copolymer, oxygen-containing copolymer, polymethacrylate or its mixture, and the flame retardan...

Embodiment 3

[0028] As preferably, the self-healing electric heating paint for building interior walls includes the following components: 15 parts of film epoxy resin, 5 parts of propylene oxide, 0.8 part of chitosan, 14 parts of graphite powder, 1 part of nano silicon dioxide, 3 parts of activated carbon acrylic fiber, 5 parts of diatomaceous earth, 2 parts of pigment, 3 parts of mica powder, 1 part of polyurethane, 3 parts of polymethacrylate, 0.5 parts of phosphate ester, TiO 2 0.3 parts of photocatalytic antibacterial material.

[0029] The bioactive enzyme formed by citric acid-modified soybean protein is solidified on the activated carbon acrylic fiber, and the propylene oxide is a cyclic molecule propylene oxide, and chitosan is extracted from shrimp and crab shells. chitosan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com