High-molecular organic soil solidifying agent and synthetic method of same

A technology of organic soil and curing agent, which is applied in the soil curing of foundation construction and various road fields. It can solve the problems of low strength, large dry shrinkage, and no curing, and achieve strong compression resistance, good curing effect, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

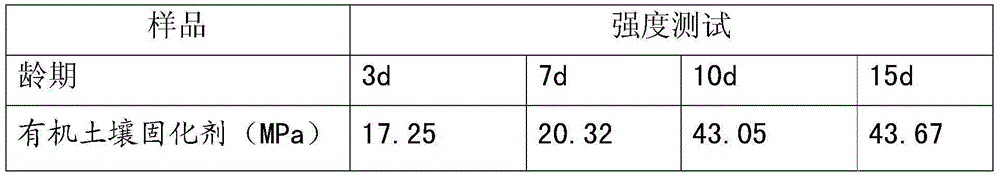

Embodiment 1

[0026] Assume with the following ratio: a kind of novel macromolecular organic soil solidifying agent that is used for road, field construction of the present invention, raw material is prepared in parts by weight: 2 parts of magnesium chloride, 3 parts of calcium chloride, 0.5 part of calcium oxide, 0.5 part of oxide Magnesium, 5 parts acrylamide, 0.4 parts ammonium persulfate, 0.6 parts potassium persulfate, 10 parts soluble cellulose, 10 parts sodium carboxymethylcellulose, 1 part sodium hydroxide, 67 parts water.

[0027] Preparation: first dissolve acrylamide into a 10% aqueous solution for later use; dissolve ammonium persulfate into a 1% aqueous solution for later use; dissolve potassium persulfate into a 1% aqueous solution for later use; add the remaining water into the reaction kettle, stir, Then heat up to 60-80°C, then add magnesium chloride, calcium chloride, calcium oxide, magnesium oxide, stir for 30 minutes, then add soluble cellulose, sodium carboxymethyl cellu...

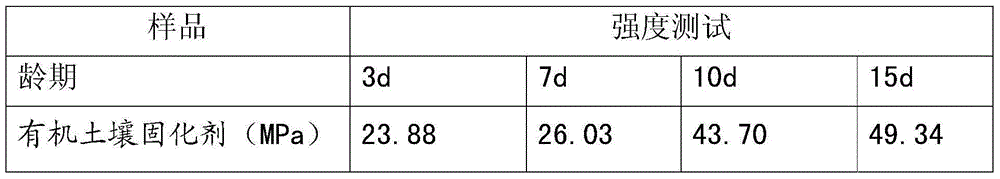

Embodiment 2

[0033] With 4 parts of magnesium chloride, 6 parts of calcium chloride, 0.5 parts of calcium oxide, 0.5 parts of magnesium oxide, 5 parts of acrylamide, 0.4 parts of ammonium persulfate, 0.6 parts of potassium persulfate, 15 parts of soluble cellulose, 10 parts of carboxymethyl cellulose Sodium plain, 1 part sodium hydroxide, 57 parts water.

[0034] Preparation: first dissolve acrylamide into a 10% aqueous solution for later use; dissolve ammonium persulfate into a 1% aqueous solution for later use; dissolve potassium persulfate into a 1% aqueous solution for later use; add the remaining water into the reaction kettle, stir, Then heat up to 60-80°C, then add magnesium chloride, calcium chloride, calcium oxide, magnesium oxide, stir for 30 minutes, then add soluble cellulose, sodium carboxymethyl cellulose, stir for 1 hour, add sodium hydroxide, stir for 30 minutes Minutes, finally add acrylamide solution, ammonium persulfate solution and potassium persulfate solution, stir, r...

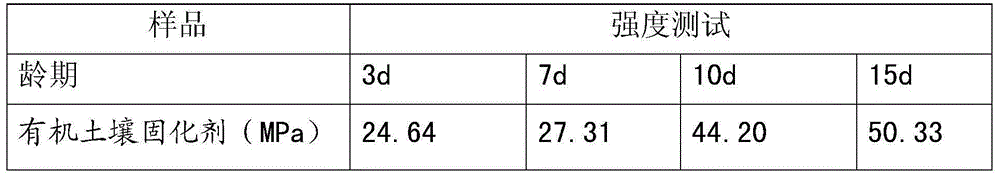

Embodiment 3

[0040] With 6 parts of magnesium chloride, 8 parts of calcium chloride, 0.5 parts of calcium oxide, 0.5 parts of magnesium oxide, 5 parts of acrylamide, 0.4 parts of ammonium persulfate, 0.6 parts of potassium persulfate, 20 parts of soluble cellulose, 15 parts of carboxymethyl cellulose Sodium plain, 1 part sodium hydroxide, 43 parts water.

[0041] Preparation: first dissolve acrylamide into a 10% aqueous solution for later use; dissolve ammonium persulfate into a 1% aqueous solution for later use; dissolve potassium persulfate into a 1% aqueous solution for later use; add the remaining water into the reaction kettle, stir, Then heat up to 60-80°C, then add magnesium chloride, calcium chloride, calcium oxide, magnesium oxide, stir for 30 minutes, then add soluble cellulose, sodium carboxymethyl cellulose, stir for 1 hour, add sodium hydroxide, stir for 30 minutes Minutes, finally add acrylamide solution, ammonium persulfate solution and potassium persulfate solution, stir, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com