A kind of polyimide fiber membrane with cross-linked morphology and preparation method thereof

A technology of polyimide fiber and fiber membrane, which is used in fiber processing, textiles and papermaking, non-woven fabrics, etc. Poor performance, no interaction and other problems, to achieve the effect of facilitating process and industrial scale preparation, good dimensional stability, and controllable degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

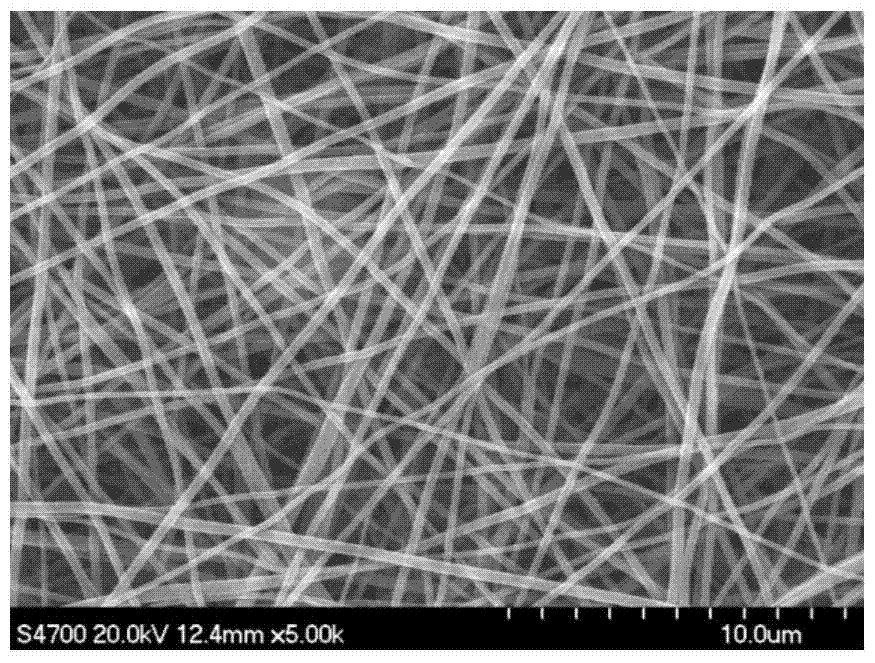

[0044] Using pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) as the dianhydride and diamine monomers respectively, and DMF as the solvent, polyamic acid solution was polycondensed with a solid content of 12%. , the polyamic acid fiber membrane was prepared by electrospinning, and the subsequent treatment processes were (a) direct high-temperature thermal imidization without solvent treatment, and the temperature was raised from room temperature to 300 ° C at a uniform speed for 120 minutes, and kept for 120 minutes; (b) ) from room temperature to 250°C at a constant speed for 100 minutes, cooled, soaked in DMF for 1 minute, and then thermally imidized, from room temperature to 300°C at a constant speed for 120 minutes, and kept at a constant speed for 120 minutes; (c) from room temperature to 80 minutes at a constant speed 200°C, cool down, soak in DMF for 1min, then thermally imidize, heat up from room temperature to 300°C at a constant speed over 120min, ...

Embodiment 2

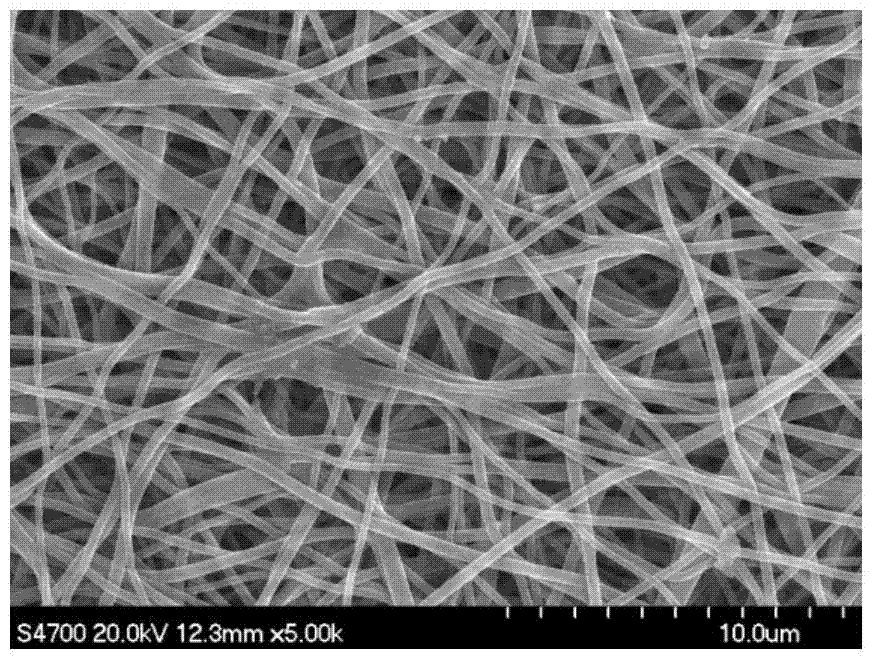

[0046] Adopt PMDA, ODA to be dianhydride and diamine monomers respectively, DMF is solvent, polycondensation obtains polyamic acid solution, solid content is 12%, prepares polyamic acid fiber membrane with electrospinning method, and subsequent processing process is respectively (a ) from room temperature to 250°C at a constant speed for 100 minutes, cooled, soaked in DMF for 10 minutes, and then thermally imidized, from room temperature to 300°C at a constant speed for 120 minutes, and kept at a constant speed for 120 minutes; (b) from room temperature to Cool at 250°C, soak in DMF for 20min, then thermally imidize, heat up from room temperature to 300°C at a constant speed over 120min, and keep warm for 120min. The morphologies of the obtained imide fiber membranes are shown in Figure 2(a) and (b). It can be seen from the figure that the polyimide fiber membranes treated with solvent for 10min and 20min have a large number of bonding points, and the longer the solvent treatm...

Embodiment 3

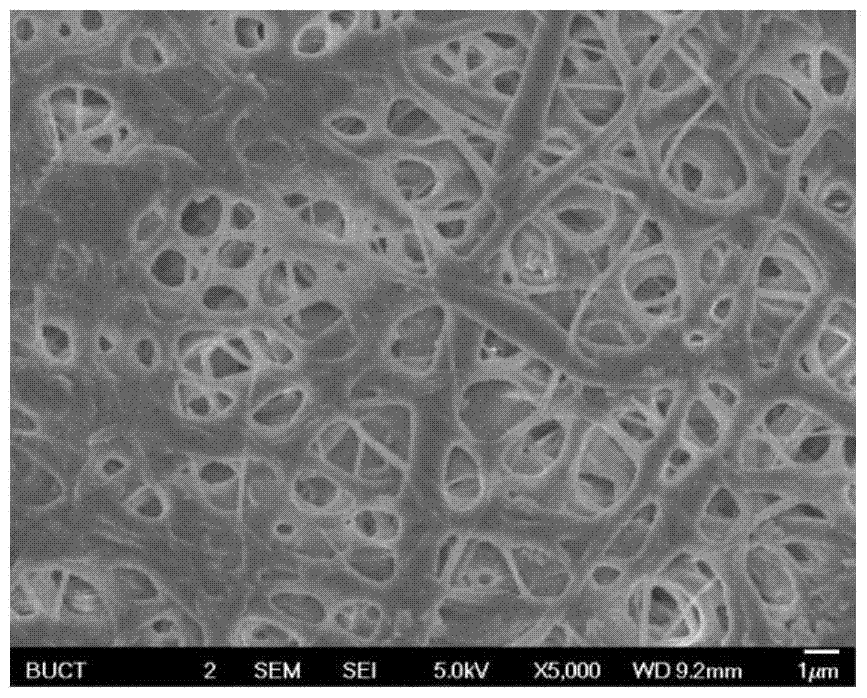

[0049] Using PMDA and ODA as dianhydride and diamine monomers respectively, and DMF as solvent, polyamic acid solution was polycondensed with a solid content of 12%, and polyamic acid fiber membrane was prepared by electrospinning method, and the subsequent treatment process was from room temperature through The temperature was raised to 250°C at a constant speed for 100 minutes, cooled, soaked in DMAc for 20 minutes, and then thermally imidized, and the temperature was raised from room temperature to 300°C at a constant speed for 120 minutes, and kept for 120 minutes. The morphology of the obtained imide fiber membrane is as follows: image 3 shown. It can be seen from the figure that the degree of crosslinking of the polyimide fiber membrane after solvent treatment for 20min is relatively large, and compared with the untreated polyimide fiber membrane, the porosity drops to 65.1% (such as Image 6 Shown), the mechanical properties are excellent, increased to 51.79MPa (such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com