Method of preparing pH value color-changeable fabric by utilizing vegetable dyes

A plant dye and fabric technology, applied in dyeing, textile and paper making, fiber treatment, etc., can solve the problems of chemical dyes endangering human health, environmental pollution, chemical dyes are difficult to degrade, etc., and achieve good acid-base change indication function, friction Good color fastness and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Grind turmeric, take the pulverized turmeric and immerse it in an ethanol solution with a volume concentration of 50% at a material-to-liquid ratio of 1:10, heat at 60°C for 2 hours, and filter through a 100-mesh sieve to remove plant residues to obtain Turmeric dye;

[0026] Step 2: Weigh potassium aluminum sulfate dodecahydrate and an appropriate amount of water relative to the mass of the cotton fabric at 5% to obtain a pretreatment solution with a bath ratio of 1:50; heat the pretreatment solution to 40°C and put it into the cotton fabric, and continue Raise the temperature to 80°C, keep it warm for 40 minutes, then take out the cotton fabric and squeeze out the water, and set aside;

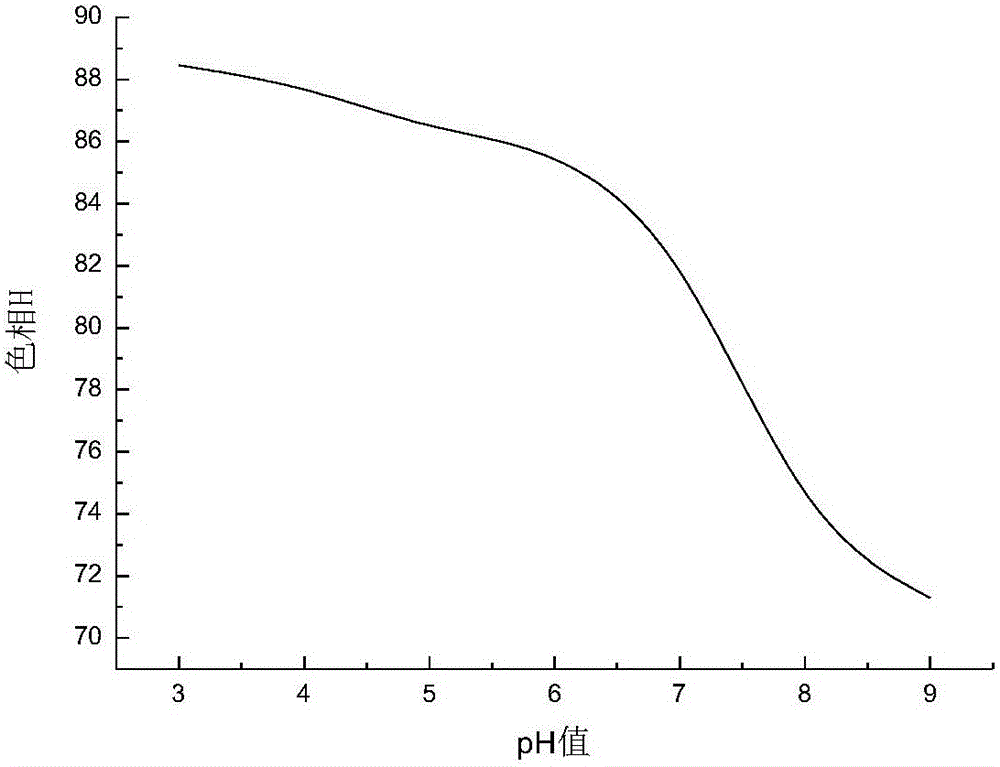

[0027] Step 3: Measure the turmeric dyeing solution obtained in step 1 according to the bath ratio of 1:51, and use a constant temperature oscillating water bath to dye the fabric. When heated to 40°C, put the cotton fabric treated in step 2 into the dyeing solution to start d...

Embodiment 2

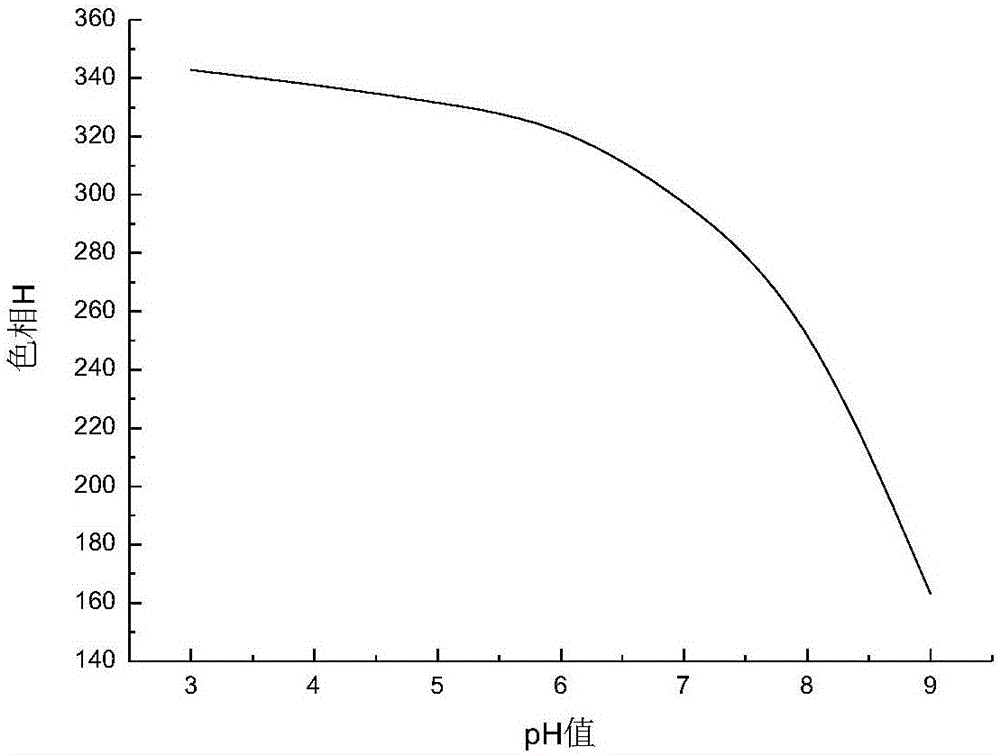

[0030] Step 1: Grind fresh mulberries, take the crushed mulberries and immerse them in an ethanol solution with a volume concentration of 50% at a material-to-liquid ratio of 1:2, heat at 60°C for 4 hours, and filter through a 100-mesh sieve to remove residues to obtain Mulberry dye;

[0031] Step 2: Weigh potassium aluminum sulfate dodecahydrate and an appropriate amount of water relative to the mass of the cotton fabric at 5% to obtain a pretreatment solution with a bath ratio of 1:50; heat the pretreatment solution to 40°C and put it into the cotton fabric, and continue Raise the temperature to 80°C, keep it warm for 40 minutes, then take out the cotton fabric and squeeze out the water, and set aside;

[0032] Step 3: Measure the mulberry dye solution obtained in step 1 according to the bath ratio of 1:85, and use a constant temperature oscillating water bath to dye the fabric. When heated to 40°C, put the cotton fabric treated in step 2 into the dye solution to start dyein...

Embodiment 3

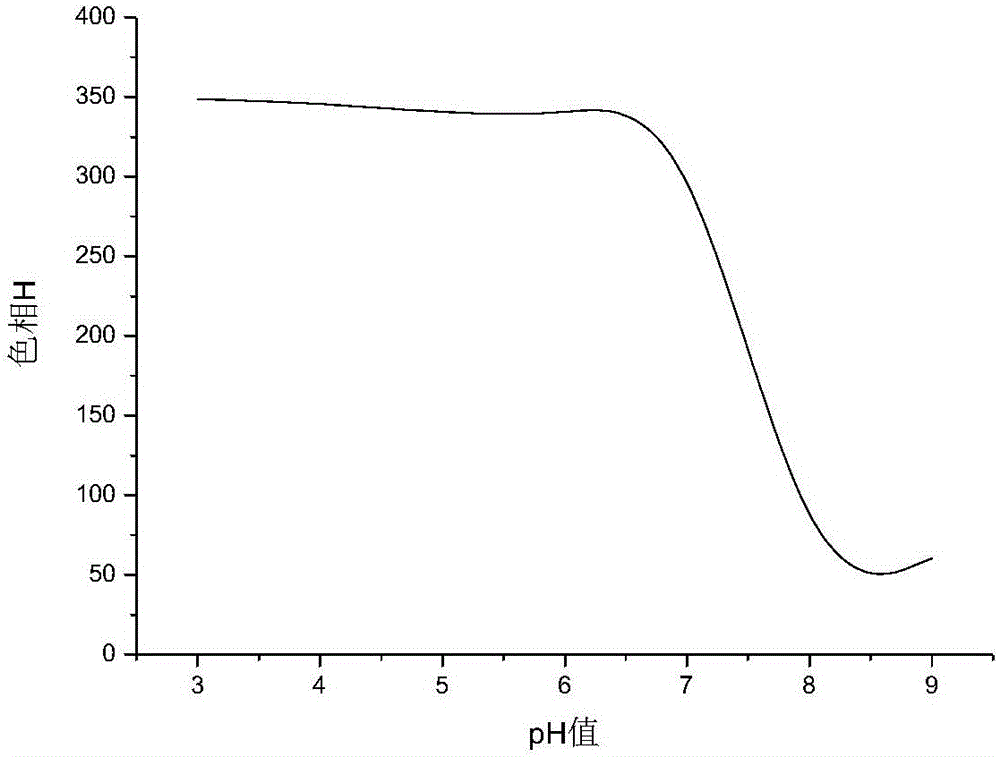

[0035] Step 1: crush the black rice, take the crushed black rice and immerse it in an ethanol solution with a volume concentration of 50% at a material-to-liquid ratio of 1:6, heat at 60°C for 4 hours, and filter through a 100-mesh sieve to remove the residue. Obtain black rice dyeing solution;

[0036] Step 2: Weigh 5% potassium aluminum sulfate dodecahydrate and appropriate amount of water relative to the mass of the fabric to obtain a pretreatment solution with a bath ratio of 1:50; heat the pretreatment solution to 40°C and put it into the silk fabric, and continue to heat up To 80 ℃, keep warm for 40 minutes, then take out the silk fabric and squeeze out the water, set aside;

[0037] Step 3: Measure the black rice dyeing solution obtained in step 1 according to the bath ratio of 1:100, use a constant temperature oscillating water bath to dye the fabric, and when heated to 40°C, put the silk fabric treated in step 2 into the dyeing solution to start dyeing, Raise the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com