Perovskite solar cell based on PCBM-modified ZnO nano-rod array and preparation method of perovskite solar cell

A technology of solar cells and nanorod arrays, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as hindering the development of solar cells, efficiency attenuation, and instability of solar cells, and achieve good results. The effect of development prospect, reduction of energy loss, and low experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

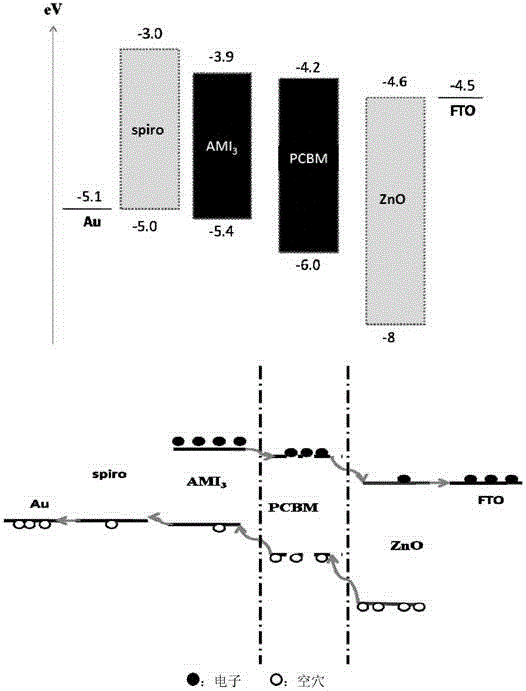

[0036] Example 1: ZnO nanorods / CH 3 NH 3 PB 3 Preparation of perovskite solar cells:

[0037] (1) Pretreatment of FTO: Cut the FTO glass sheet into square glass samples with an area of 2cm*2cm, then use deionized water, acetone, alcohol, and deionized water to carry out ultrasonic cleaning for 20 minutes, and the surface of the glass sheet Impurities are cleaned, and then cleaned with ultraviolet ozone (UV) for 15 minutes to remove organic matter attached to the surface.

[0038] (2) Preparation of ZnO seed layer: using methanol as solvent, prepare 3mmol / L zinc acetate (Zn(CH 3 COO) 2 ) solution, stirred for 10 minutes, and then started to spin-coat on the FTO glass sample at a rotation speed of 3000r / min for 15s, dried at 100°C for 15 minutes, and then transferred to a muffle furnace for annealing for 1h.

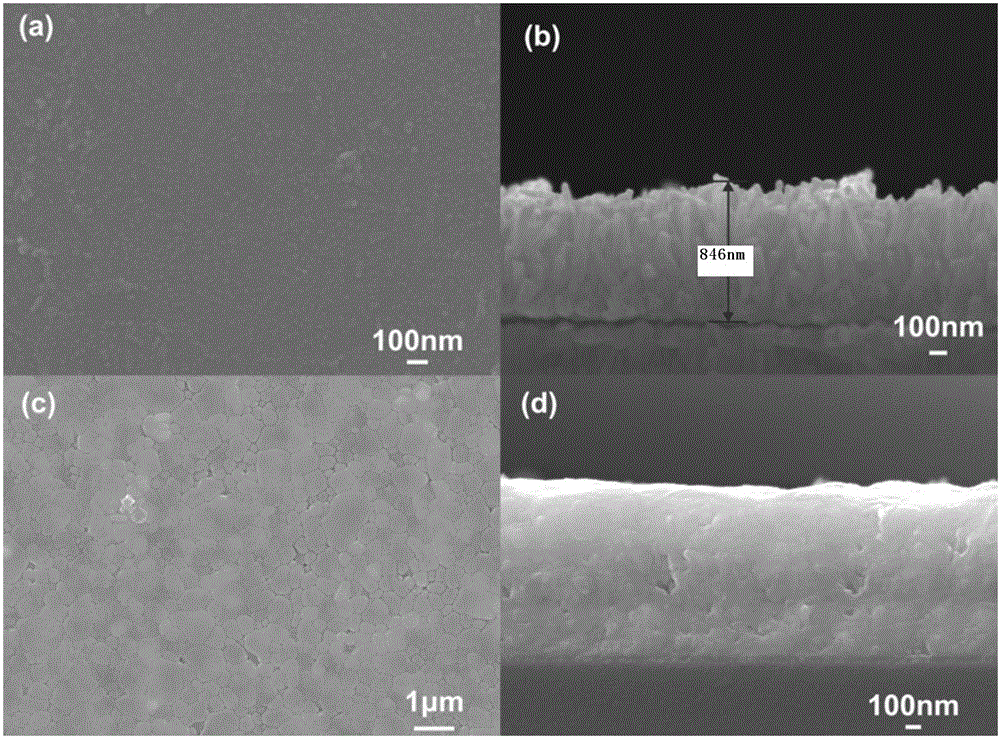

[0039] (3) Preparation of ZnO nanorods: grow ZnO nanorods in a water bath on the FTO glass sample with a ZnO seed layer, and the water bath solution composition is ...

Embodiment 2

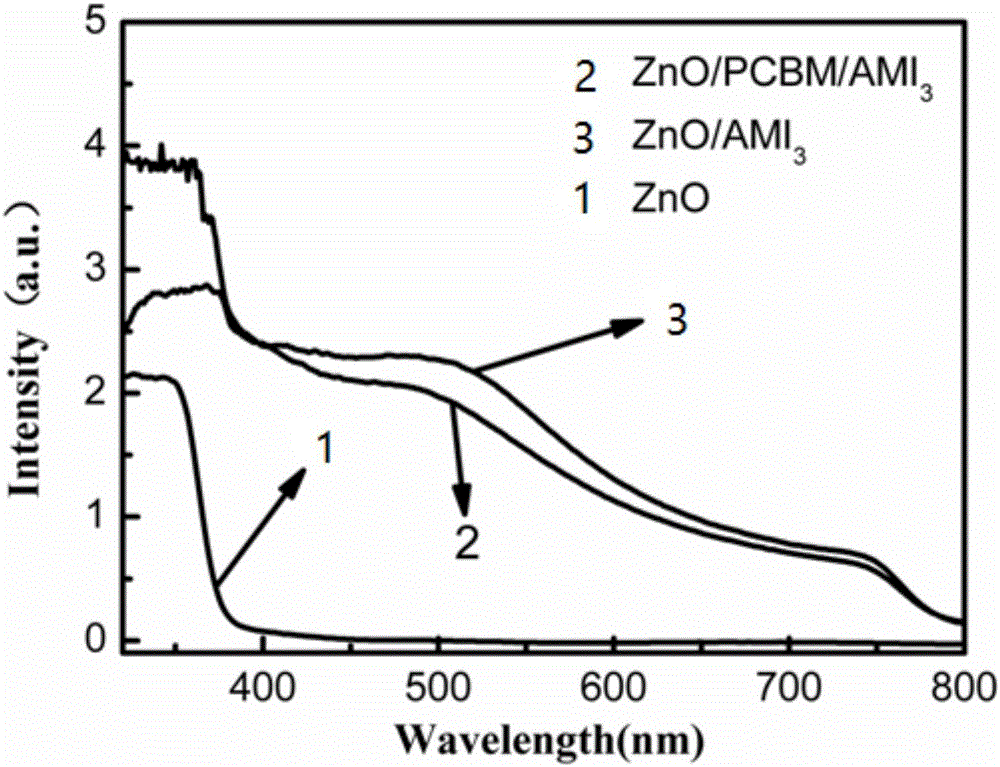

[0044] Example 2: ZnO nanorods / PCBM / CH 3 NH 3 PB 3 Preparation of organic-inorganic hybrid perovskite solar cells:

[0045] (1), (2), (3) steps are identical with embodiment 1;

[0046] (4) Incorporation of PCBM: first, ZnO nanorods were cleaned with ultraviolet ozone (UV) for 15 minutes, and then a certain concentration of PCBM solution was prepared with chlorobenzene as a solvent, and PCBM was thrown into ZnO nanorods by spin coating, The spin-coating speed is 3000r / min, the spin-coating time is 10s, and then placed overnight in the glove box.

[0047] (5) Two-step synthesis of the perovskite layer (CH 3 NH 3 PB 3 ): The first step is to spin-coat PbI 2 , that is, using DMF (N,N-dimethylformamide) as a solvent to prepare 1mmol / L (0.462g) of PbI 2 solution, stirred at a constant temperature of 70°C for 4h, and then the PbI 2 Throw it on the PCBM layer, the spin coating speed is 3000r / min, and the time is 15s. After spinning, put it on the drying table and bake for 5m...

Embodiment 3

[0051] Example 3: PCBM / CH 3NH 3 PB 3 Fabrication of Structural Perovskite Solar Cells

[0052] (1) Pretreatment of FTO: Cut the FTO glass sheet into square glass sheets with an area of 2cm*2cm, then use deionized water, acetone, alcohol, and deionized water to carry out ultrasonic cleaning for 20 minutes, and the surface of the glass sheet Impurities are cleaned, and then cleaned with ultraviolet ozone (UV) for 15 minutes to remove organic matter attached to the surface.

[0053] (2) Preparation of ZnO seed layer: using methanol as solvent, prepare 3mM zinc acetate (Zn(CH 3 COO) 2 ) solution, stirred for 10 minutes, and then started spin-coating at a rotation speed of 3000r / min for 15s, dried at 100°C for 15 minutes, and then transferred to a muffle furnace for annealing for 1h.

[0054] (3) Incorporation of PCBM: first, ZnO nanorods were cleaned with UV for 15 minutes, and with chlorobenzene as a solvent, a PCBM solution with a concentration of 2--2.5wt% was prepared, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com