Polyethylene glycol-modified vitamin E liposome and its preparation method and use

A polyethylene glycol and vitamin technology, applied in the field of daily care products, can solve problems such as insecurity, and achieve the effects of being beneficial to use, improving stability and improving encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

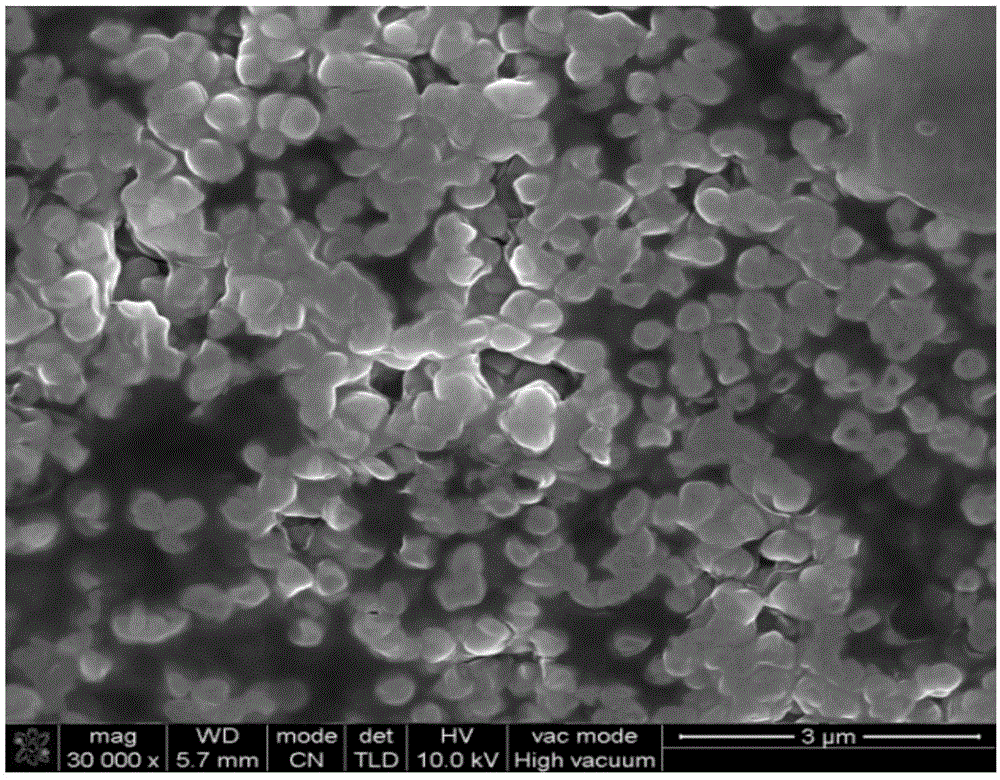

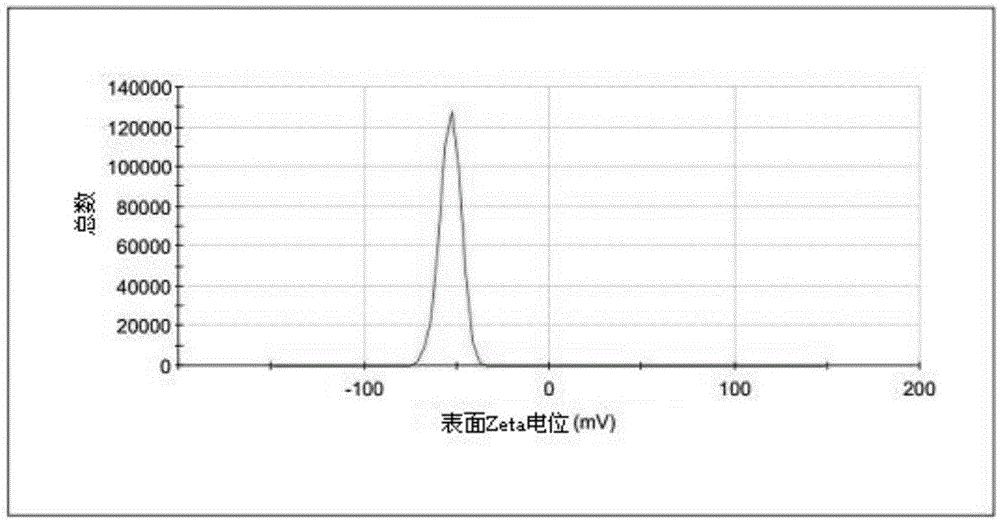

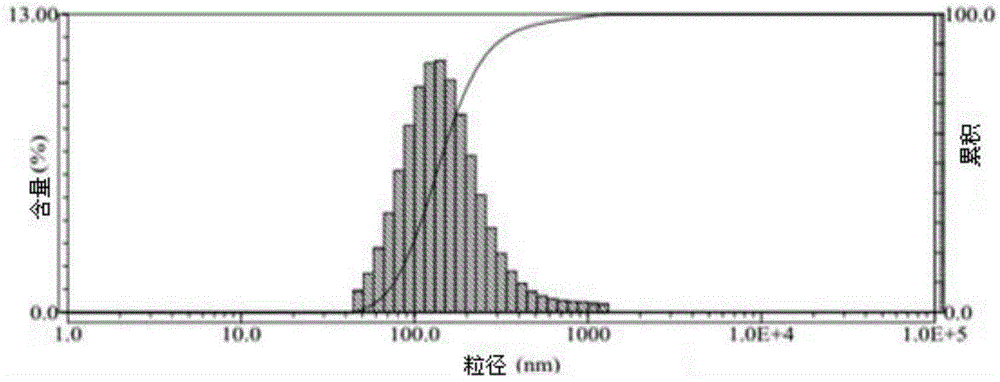

Image

Examples

Embodiment 1

[0040] A preparation method of polyethylene glycol-modified vitamin E liposomes, comprising the following preparation steps:

[0041] (1) Weigh 0.08g of egg yolk lecithin, 0.08g of cholesterol, 0.04g of vitamin E and 0.4g of sodium cholate into a conical flask, add 20ml of a mixed solvent of chloroform and methanol with a volume ratio of 1:1, and stir to dissolve Obtain a mixed solution evenly;

[0042] (2) The mixed solution is placed in a rotary evaporator, and the solvent is removed by rotating vacuum in a constant temperature water bath at 42° C. to obtain a liposome film attached to the wall of the device;

[0043] (3) 0.4g polyethylene glycol is dissolved with the phosphate buffer solution of pH7.4, and preparation mass concentration is the polyethylene glycol solution of 1%, then joins in the rotary evaporator of step (2), in 40 ℃ of water baths Rotate hydration for 1 hour under the condition to obtain orange liposome suspension;

[0044] (4) Ultrasonic dispersion of ...

Embodiment 2

[0049] A preparation method of polyethylene glycol-modified vitamin E liposomes, comprising the following preparation steps:

[0050] (1) Weigh 0.08g of soybean lecithin, 0.08g of cholesterol, 0.04g of vitamin E and 0.8g of sodium cholate into a conical flask, add 20ml of a mixed solvent of chloroform and methanol with a volume ratio of 1:1, and stir to dissolve Obtain a mixed solution evenly;

[0051] (2) The mixed solution is placed in a rotary evaporator, and the solvent is removed by rotating vacuum in a constant temperature water bath at 60° C. to obtain a liposome film attached to the wall of the device;

[0052] (3) 0.4g polyethylene glycol is dissolved with the phosphate buffer solution of pH7.4, and preparation mass concentration is the polyethylene glycol solution of 10%, then joins in the rotary evaporator of step (2), in 60 ℃ of water baths Rotate hydration for 1 hour under the condition to obtain orange liposome suspension;

[0053] (4) Ultrasonic dispersion of ...

Embodiment 3

[0057] A preparation method of polyethylene glycol-modified vitamin E liposomes, comprising the following preparation steps:

[0058] (1) Weigh 0.08g of egg yolk lecithin, 0.08g of cholesterol, 0.04g of vitamin E and 1.0g of sodium cholate into a conical flask, add 20ml of a mixed solvent of chloroform and methanol with a volume ratio of 1:1, and stir to dissolve Obtain a mixed solution evenly;

[0059] (2) The mixed solution is placed in a rotary evaporator, and the solvent is removed by rotating vacuum in a constant temperature water bath at 80° C. to obtain a liposome film attached to the wall of the device;

[0060] (3) 0.8g polyethylene glycol is dissolved with the phosphate buffer solution of pH7.4, and preparation mass concentration is the polyethylene glycol solution of 20%, then joins in the rotary evaporator of step (2), in 60 ℃ of water baths Rotate hydration for 1 hour under the condition to obtain orange liposome suspension;

[0061] (4) Ultrasonic dispersion of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com