Mesoporous organosilica nanospheres with double-layer egg yolk-eggshell structure and preparation method thereof

A technology of organic silicon oxide and nanospheres, which is applied in the field of nanomaterials to achieve the effect of simple synthesis process, simple synthesis method and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

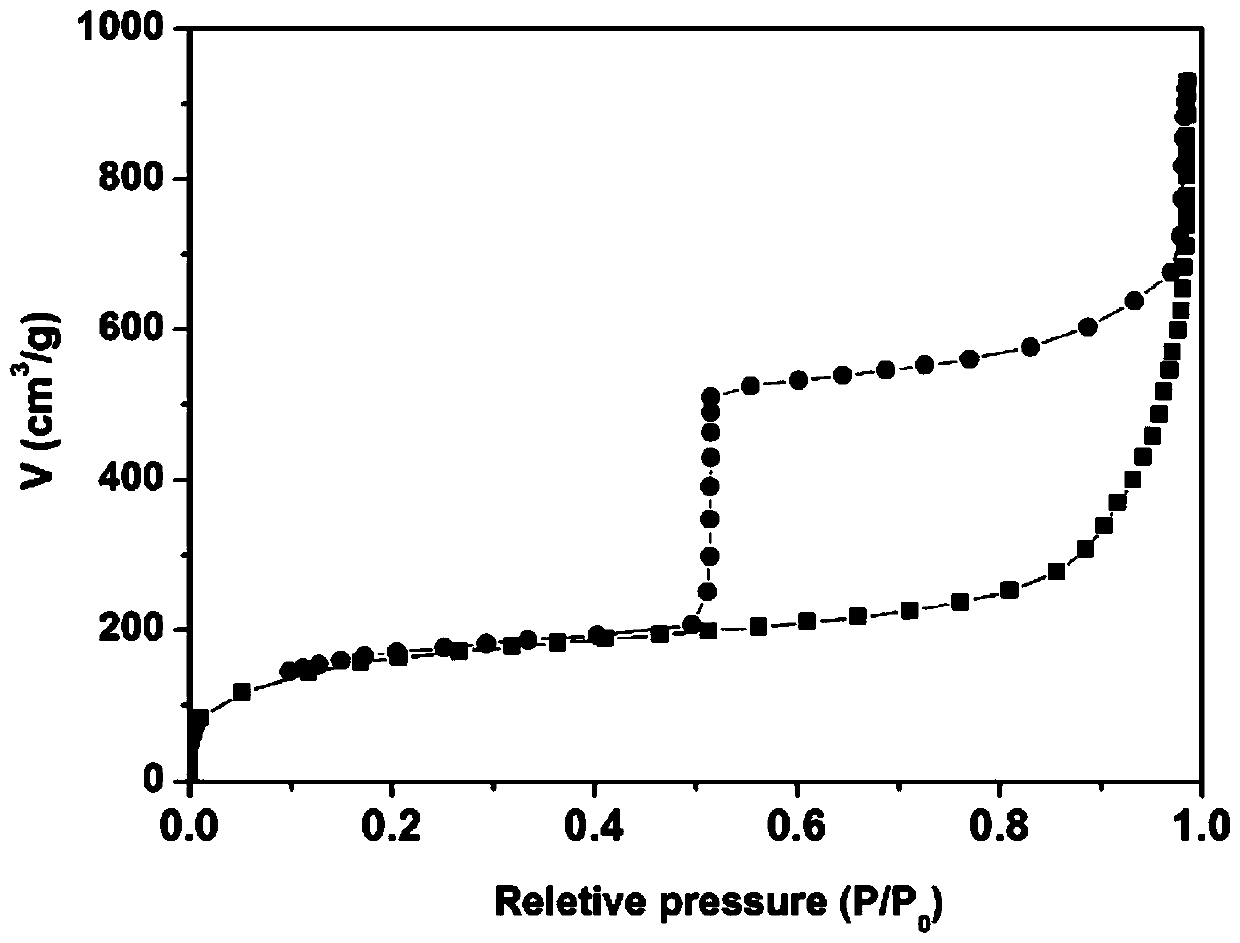

[0034] (1) Dissolve 0.08g of surfactant in a mixed solution containing 1ml of ammonia water, 30ml of ethanol and 75ml of water, and mix 0.25ml of tetraethyl orthosilicate and 0.1ml of bis[γ- (Triethoxysilyl) propyl] tetrasulfide mixture was added to the above mixed solution, reacted for 24h, the tetraethyl orthosilicate, surfactant, bis[γ-(triethoxysilyl ) Propyl] tetrasulfide, ethanol and water molar ratio 1:0.1:0.18:461:3728, wherein the NH contained in the ammonia 3 The mass percentage is 26%.

[0035](2) Centrifuge the mixed solution of step (1), wash with alcohol, transfer to the mixed solution of 1ml ammonia water, 29ml ethanol and 70ml water, add 0.1g surfactant, 0.125ml tetraethyl orthosilicate, 0.1ml of 1.2 -bis(triethoxysilyl)ethane, reacted for 24h at 35°C under stirring at 1100rpm, the tetraethyl orthosilicate, 1.2-bis(triethoxysilyl)ethane, surface The molar ratio of the active agent, water and ethanol is 1:0.5:0.5:7000:900, wherein the NH contained in the ammon...

Embodiment 2

[0040] (1) Dissolve 0.16g of surfactant in a mixed solution containing 1ml of ammonia water, 30ml of ethanol and 75ml of water, and mix 0.25ml of tetraethyl orthosilicate and 0.1ml of bis[γ- (Triethoxysilyl) propyl] tetrasulfide mixture was added to the above mixed solution, reacted for 24h, the tetraethyl orthosilicate, surfactant, bis[γ-(triethoxysilyl ) Propyl] the molar ratio of tetrasulfide, ethanol and water is 1:0.4:0.18:461:3728, wherein the NH contained in the ammonia 3 The mass percentage is 26%.

[0041] (2) Centrifuge the mixed solution of step (1), wash with alcohol, transfer to a mixed solution containing 1ml of ammonia, 30ml of ethanol and 75ml of water, add 0.16g of surfactant, 0.125ml of tetraethyl orthosilicate and 0.12 ml of 1.2-bis(triethoxysilyl)ethane was reacted for 12 hours at 35°C under the condition of stirring at 1200rpm. The tetraethyl orthosilicate, 1.2-bis(triethoxysilyl)ethane The molar ratio of alkanes, surfactants, water and ethanol is 1:0.6:...

Embodiment 3

[0046] (1) Dissolve 0.2g surfactant in a mixed solution of 1ml ammonia water, 30ml ethanol and 75ml water, mix 0.25ml tetraethyl orthosilicate and 0.1ml bis[γ-( Triethoxysilyl) propyl] tetrasulfide mixture is added to the above-mentioned mixed solution, reacted for 3h, the tetraethyl orthosilicate, surfactant, bis[γ-(triethoxysilyl) The molar ratio of propyl]tetrasulfide, ethanol and water is 1:0.5:0.18:461:3728. NH contained in ammonia water 3 The mass percentage is 26%.

[0047] (2) Centrifuge the mixed solution of step (1), wash with alcohol, transfer to the mixed solution of 1ml ammonia water, 32ml ethanol and 90ml water, add 0.18g surfactant, 0.125ml tetraethyl orthosilicate and 0.14ml 1.2-bis(triethoxysilyl)ethane, reacted for 3h at 35°C and 500rpm stirring, the tetraethyl orthosilicate, 1.2-bis(triethoxysilyl)ethane , the molar ratio of surfactant, water and ethanol is 1:0.7:0.9:9000:1000, wherein the NH contained in the ammonia 3 The mass percentage is 26%.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com