Efficient Bi2S3-BiFeO3 composite visible-light-driven photocatalyst prepared through in-situ growth with chemical corrosion method and application of Bi2S3-BiFeO3 composite visible-light-driven photocatalyst

An in-situ growth and chemical corrosion technology is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and chemical/physical processes. reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

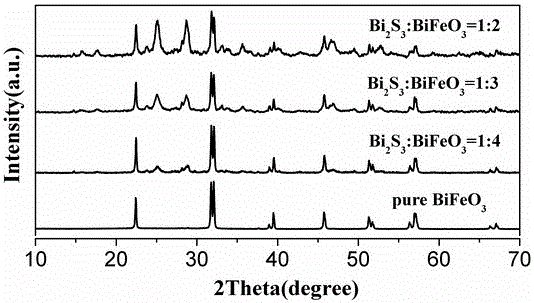

[0023] The key technology for realizing the present invention is to prepare bismuth sulfide-bismuth ferrite photocatalyst, and the ratio of bismuth sulfide and bismuth ferrite in the catalyst is 1:2-1;4.

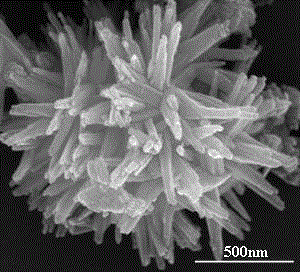

[0024] In order to achieve the above object, the present invention provides the following technical scheme: a chemical corrosion method in situ growth to prepare highly efficient bismuth sulfide-bismuth ferrite composite visible light catalyst, the method adopts the sol-gel method to synthesize bismuth ferrite, and utilizes the hydrothermal method at the same time The original taste of bismuth sulfide is grown on the surface of bismuth ferrite, which is characterized in that the main steps are:

[0025] (1) dissolving bismuth salt and iron salt in an organic solvent respectively to form an organic solution containing bismuth salt and an organic solution containing iron salt;

[0026] (2) Fully mixing the organic solution containing bismuth salt and the organic solution conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com