Micro-nano structure bismuth oxide material and preparation method thereof

A micro-nano structure, bismuth oxide technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problems of no adsorption effect, unobtainable preparation methods, etc. Simple preparation method, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The concrete steps of preparation are:

[0033] In step 1, an organic solvent is first prepared according to the volume ratio of ethanol to ethylene glycol of 1.8:1. Then dissolve the soluble bismuth salt in an organic solvent to obtain a 0.02 mol / L soluble bismuth salt solution; wherein, the soluble bismuth salt is bismuth nitrate pentahydrate.

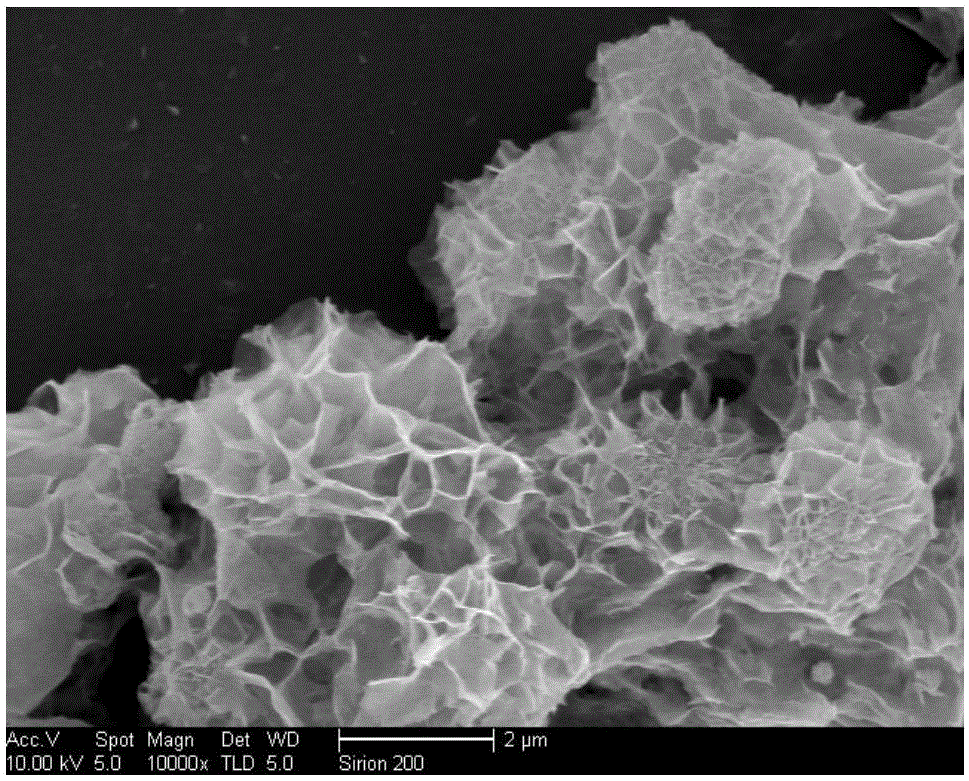

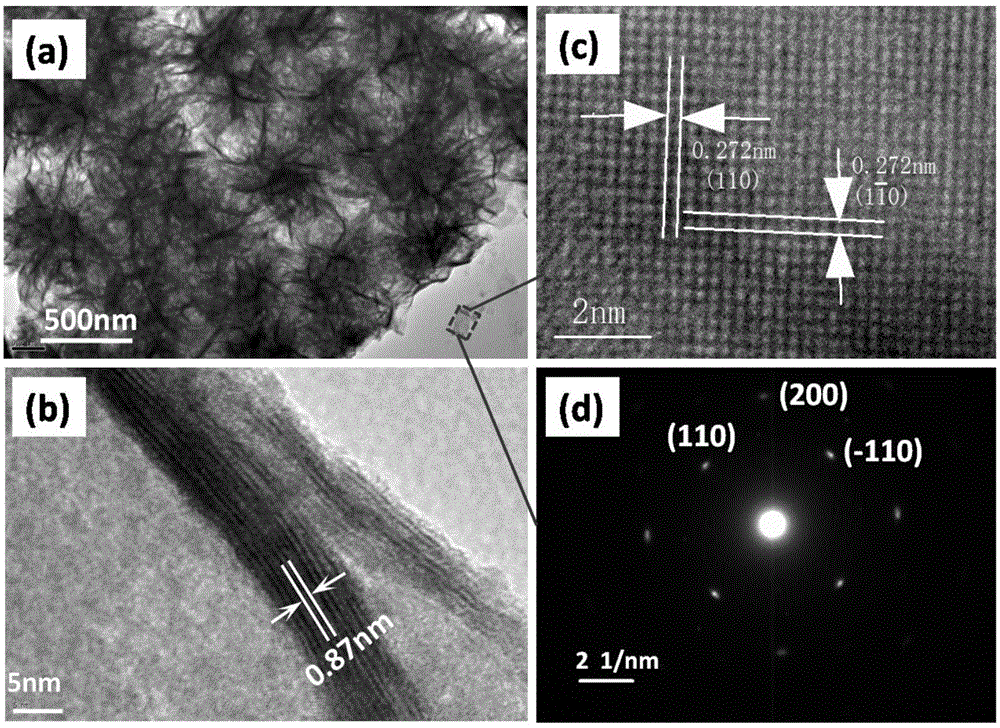

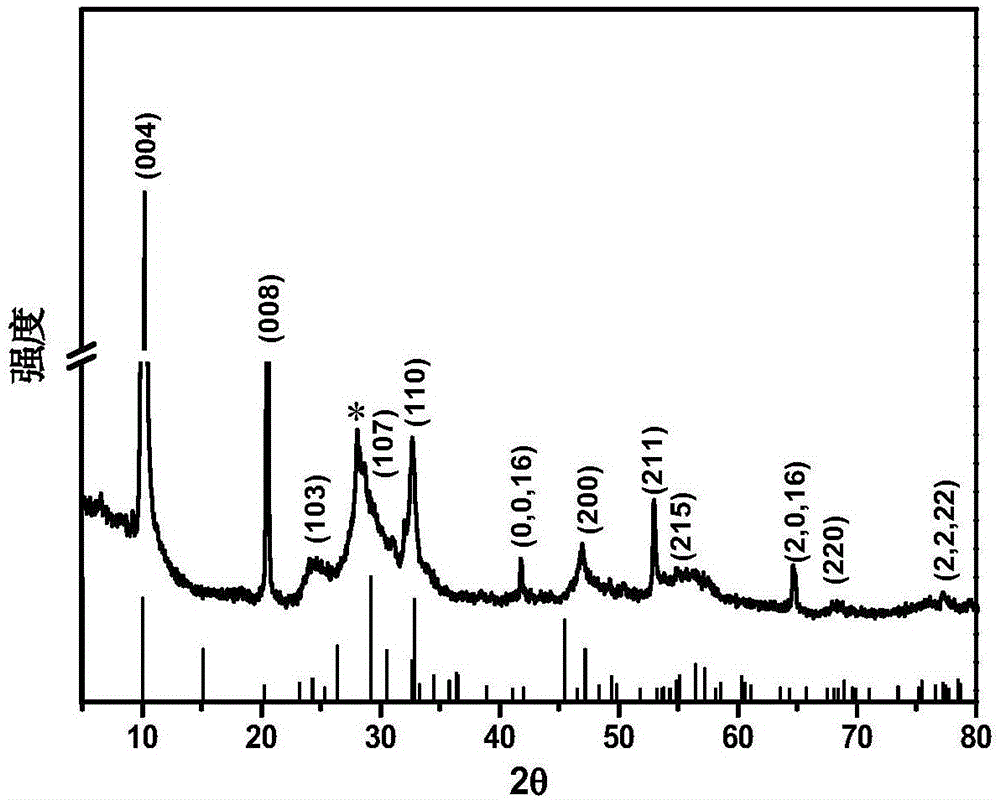

[0034] In step 2, first place the soluble bismuth salt solution at 150° C. for a closed reaction for 14 hours to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 8000r / min, and the time is 6min, and the washing process is to use deionized water to separate the solid matter Carry out cleaning, and drying treatment is to place the solid after cleaning to dry at 50 ℃, and the preparation is similar to figure 1 and figure 2 shown, and as image 3 The micro-nanostr...

Embodiment 2

[0036] The concrete steps of preparation are:

[0037] In step 1, an organic solvent is first prepared according to the volume ratio of ethanol to ethylene glycol of 1.9:1. Then dissolve the soluble bismuth salt in an organic solvent to obtain a 0.03 mol / L soluble bismuth salt solution; wherein, the soluble bismuth salt is bismuth nitrate pentahydrate.

[0038] Step 2, first place the soluble bismuth salt solution at 155° C. for 13 hours in a closed reaction to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 8500r / min, and the time is 5min, and the washing process is to use deionized water to separate the solid matter Carry out cleaning, and drying process is to place the solid after cleaning to dry at 55 ℃, and make a product similar to figure 1 and figure 2 shown, and as image 3 The micro-nanostructure bis...

Embodiment 3

[0040] The concrete steps of preparation are:

[0041] Step 1, first prepare an organic solvent according to the ratio of ethanol to ethylene glycol volume ratio of 2:1. Then dissolve the soluble bismuth salt in an organic solvent to obtain a 0.04 mol / L soluble bismuth salt solution; wherein, the soluble bismuth salt is bismuth nitrate pentahydrate.

[0042] Step 2, first place the soluble bismuth salt solution at 160° C. for 12 hours in a closed reaction to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 9000r / min, and the time is 4min, and the washing process is to use deionized water to separate the solid matter Carry out cleaning, drying process is to place the solid matter after cleaning to dry at 60 ℃, make such as: figure 1 and figure 2 shown, and as image 3 The micro-nanostructure bismuth oxide mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com