Chemical pharmaceutical wastewater pretreatment system

A technology for pharmaceutical wastewater and pretreatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of large collection and adjustment devices, many drainage points, and large fluctuation range. , to achieve the effect of advanced process technology, improved biodegradability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

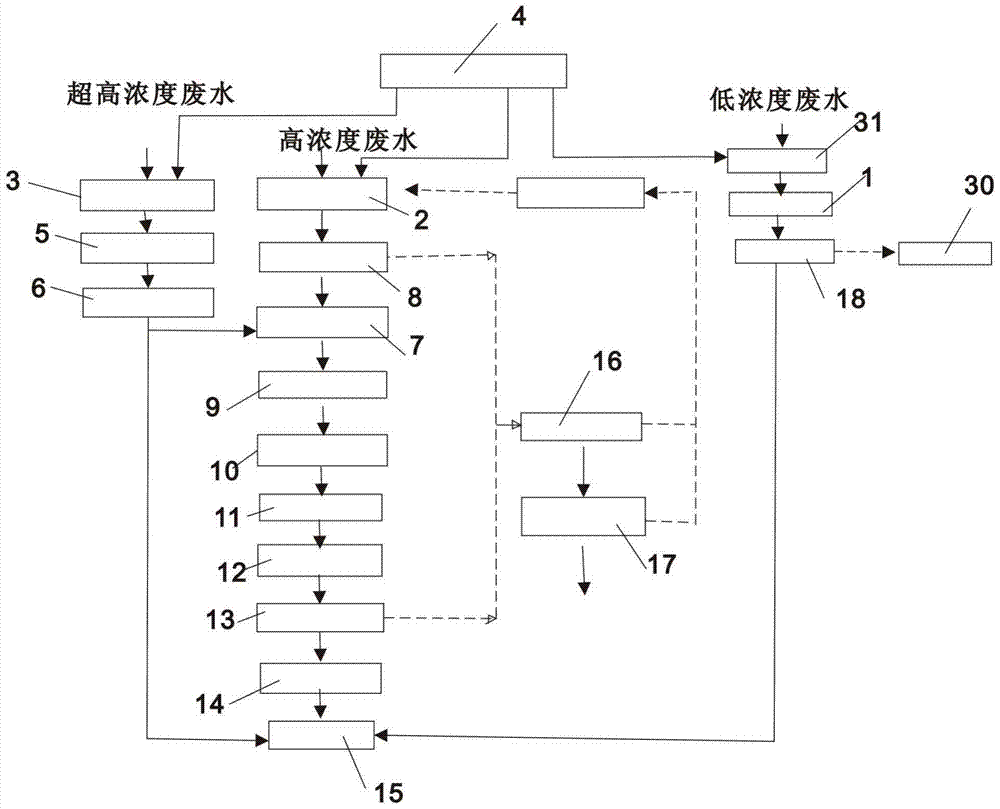

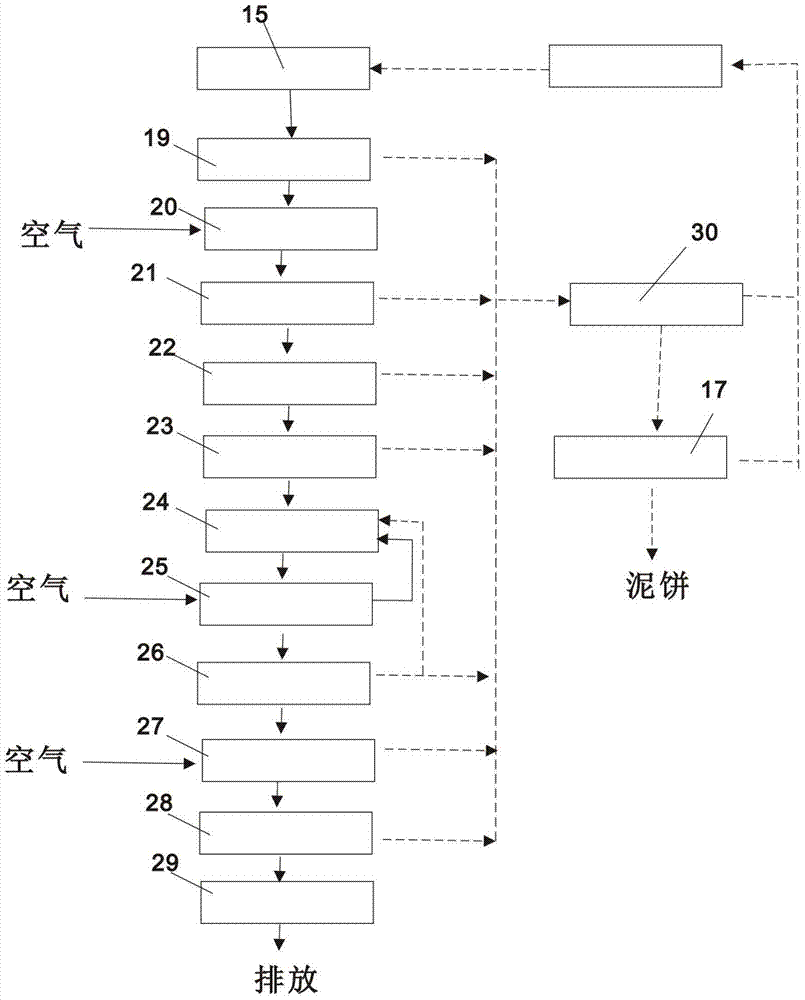

[0044] 1. Pretreatment system,

[0045] Low-concentration wastewater collection pool 1, high-concentration wastewater collection pool 2, ultra-high-concentration wastewater collection pool 3, and accident pool 4, accident pool 4 is connected with low-concentration wastewater collection pool 1, high-concentration wastewater collection pool 2, and ultra-high-concentration wastewater respectively Pool 3 connected.

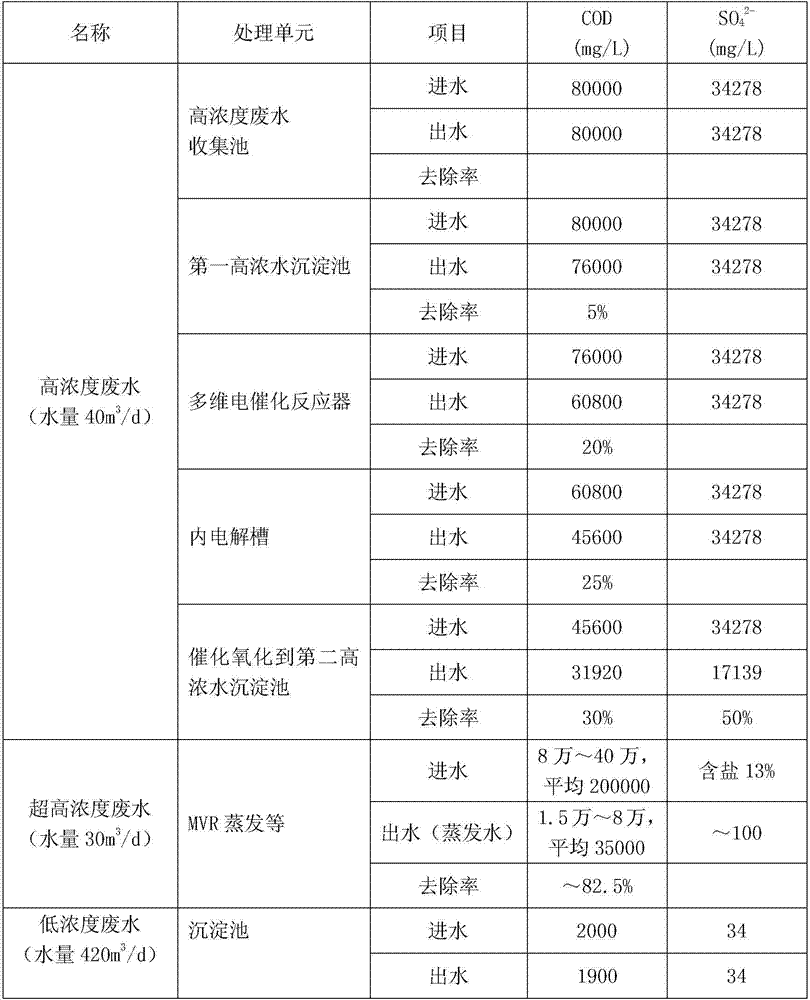

[0046] We divide the terminal wastewater in the factory area into three categories, one is ultra-high concentration wastewater COD greater than 80,000 mg / L (COD is generally: 80,000 to 400,000 mg / L); the other is high concentration wastewater (2000mg / L≤COD≤ 80,000 mg / L); third, the COD of low-concentration wastewater is less than or equal to 2,000 mg / L (the average COD is 2,000 mg / L).

[0047] Ultra-high-concentration wastewater and high-concentration wastewater come from production wastewater. Ultra-high-concentration wastewater is mainly characterized by high COD c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com