Method and device for separating high-purity longifolene

A longifolene and high-purity technology, applied in the field of turpentine deep processing, can solve the problems of high energy consumption, inability to fully utilize resources, and generate waste, and achieve the effects of easy tower kettle temperature, energy saving, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

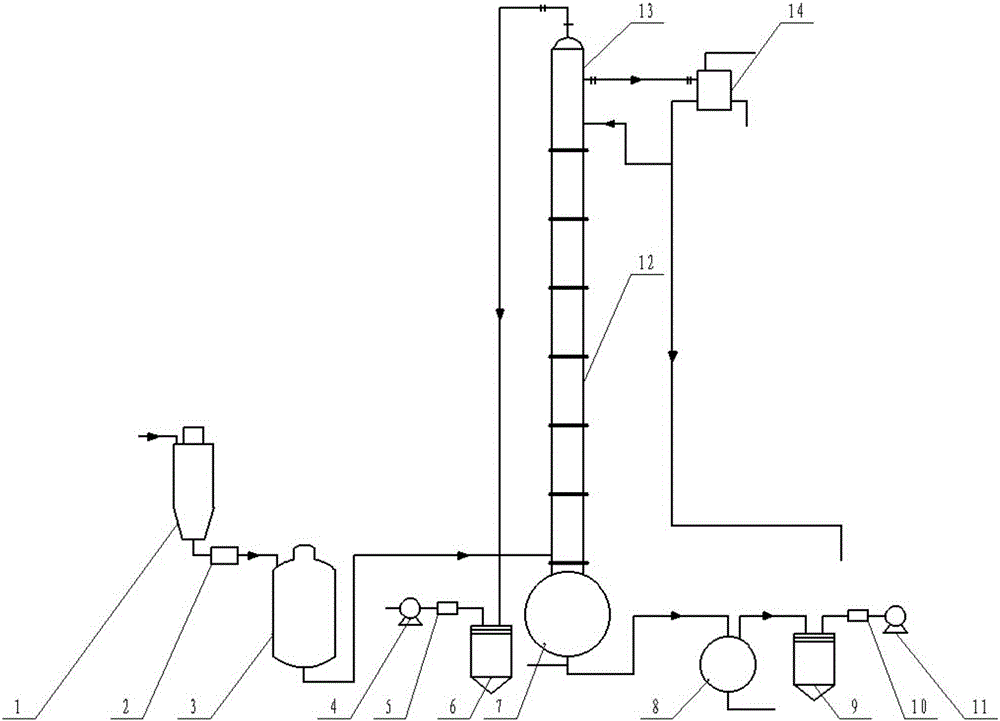

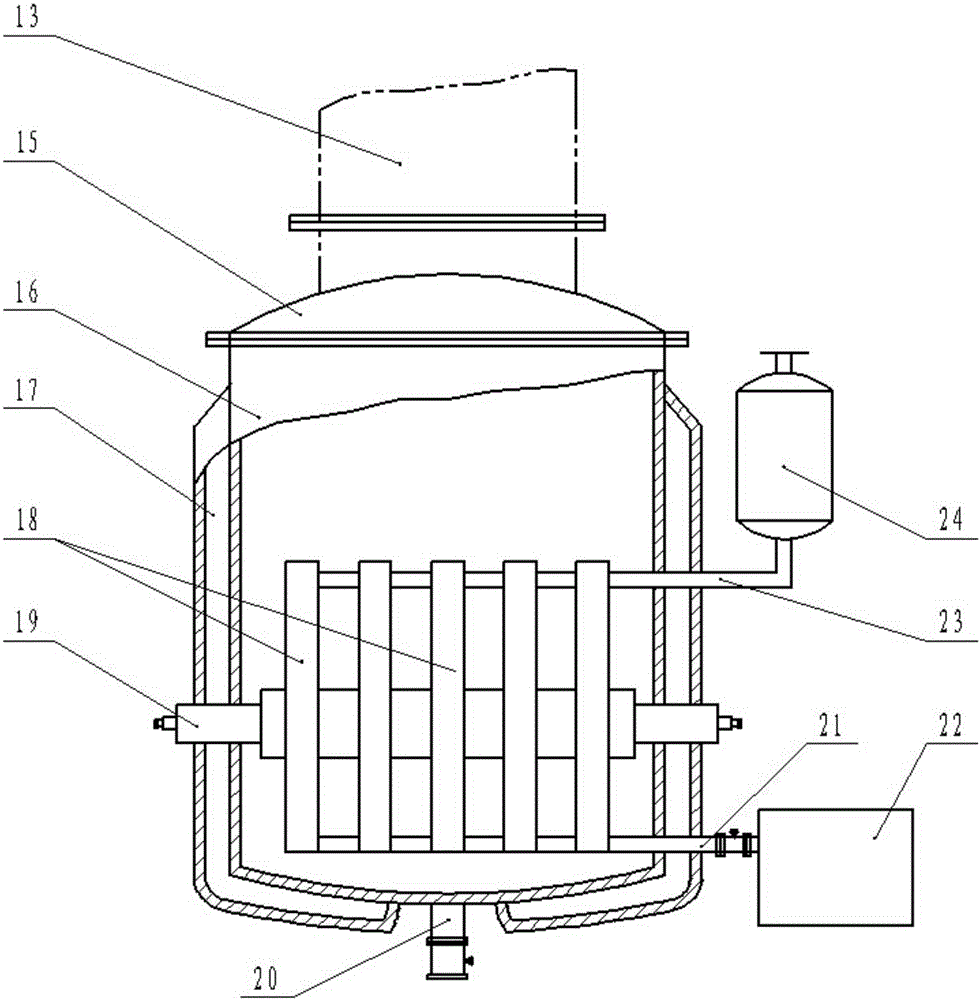

[0036] A device for separating high-purity longifolene, comprising a decolorization kettle 1, a filter 2, a raw material storage tank 3, a vacuum pump A4, a tail gas removal tank A5, a vacuum buffer tank A6, a rectification tower tank 7, a raffinate tank 8, Rectification column body 12 , condenser 13 and cooler 14 . The decolorizing kettle 1, the filter 2 and the raw material storage tank 3 are connected in sequence through pipelines, and the feed port of the raw material storage tank 3 is connected with the rectification tower kettle 7 through pipelines. The rectification tower kettle 7 is equipped with a heating system, and the rectification tower kettle The outlet of 7 is connected with rectifying tower body 12, and the top of rectifying tower body 12 is condenser 13, and cooler 14 is arranged below condenser 13; The top of rectifying tower body 12 is connected with vacuum buffer tank A5, exhaust The removal tank A6 and the vacuum pump A4 are connected successively; the raf...

Embodiment 2

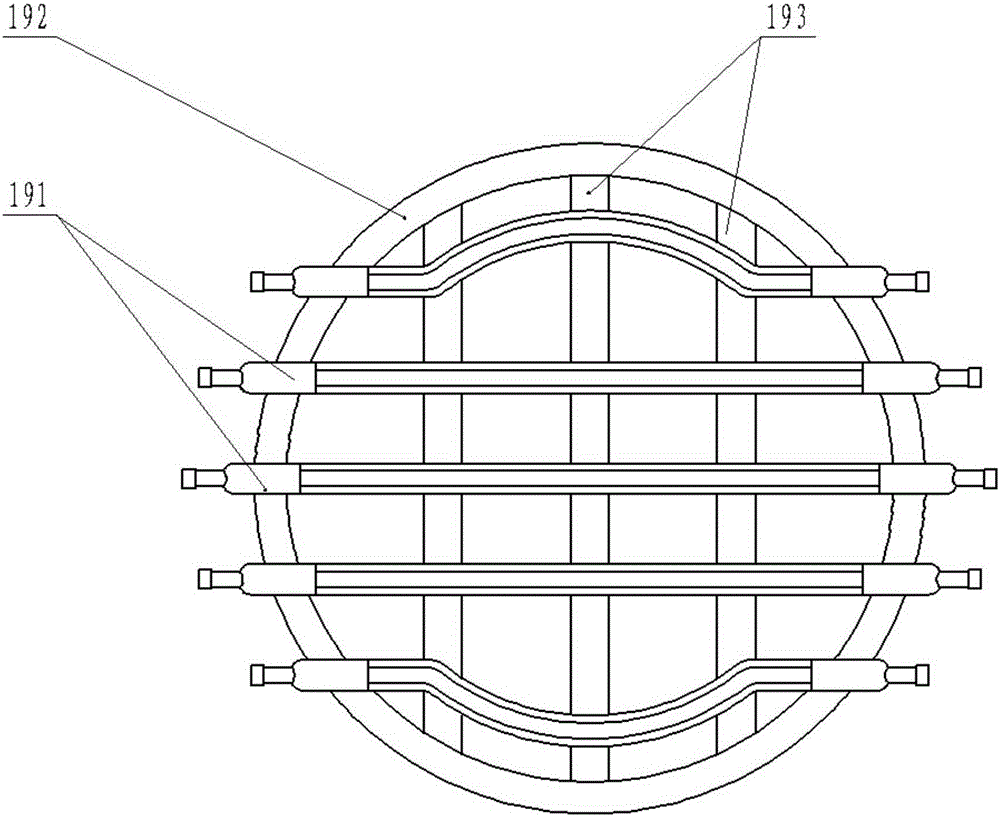

[0039]The method for separating high-purity longifolene using the device described in Example 1 is to use a vacuum pump A4 to discharge the air in the rectification tower body 12 to make the vacuum degree in the rectification tower body 12 ≤ -0.09MPa. Using negative pressure, the heavy turpentine is transported from the raw material storage tank 3 to the still 7 of the rectification tower. Before extracting longifolene, heavy turpentine is preheated to 55-60°C in the raw material storage tank. Open the heating electric tube 191 in the heating system to heat up the temperature and heat the raw material in the rectification tower still 7, and open the water inlet valve of the condenser 13 and the cooler 14 on the top of the rectification tower body 12 at the same time. The temperature of the rectification tower bottom 7 is kept at 120-130°C, the temperature of the rectification tower body 12 is kept at 100-110°C, and the total reflux is 0.5-1.5h, and the reflux ratio is 6:1, and...

Embodiment 3

[0041] The method for separating high-purity longifolene using the device described in Example 1 is to use a vacuum pump A4 to discharge the air in the rectification tower body 12 to make the vacuum degree in the rectification tower body 12 ≤ -0.09MPa. Using negative pressure, the heavy turpentine is transported from the raw material storage tank 3 to the still 7 of the rectification tower. Before extracting longifolene, heavy turpentine is preheated to 55-60°C in the raw material storage tank. Open the heating electric tube 191 in the heating system to heat up the temperature and heat the raw material in the rectification tower still 7, and open the water inlet valve of the condenser 13 and the cooler 14 on the top of the rectification tower body 12 at the same time. The temperature of the rectification tower bottom 7 is kept at 140-150°C, the temperature of the rectification tower body 12 is kept at 100-110°C, and the total reflux is 0.5-1.0h, and the reflux ratio is 8:1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com