Production technology of purified glutamic acid

A production process, glutamic acid technology, applied in the field of refined glutamic acid production process, can solve the problems of poor internal mass transfer of microbial carriers, unreasonable microbial compatibility, and many feeding times, so as to reduce the amount of sludge produced, The effect of low operating cost and increased microbial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A production process for refined glutamic acid, comprising the steps of:

[0032] Use a high-speed disk separator to separate the glutamic acid feed liquid and cell protein in the fermentation broth, and remove the fermentation cells. The speed of the high-speed disk separator to separate the cell protein is 4000r / min;

[0033] The glutamic acid feed liquid is pumped into the decolorization tank for decolorization treatment, and powdered activated carbon accounting for 2% of the glutamic acid feed liquid mass is added to the decolorization tank. The temperature in the decolorization tank is controlled at 45°C, and concentrated after 30 minutes of decolorization. It is: temperature 70°C, vacuum degree -0.1kpa, primary crystallization to obtain glutamic acid crude crystals and primary mother liquor; crude crystals for decolorization, separation and iron removal, secondary crystallization to obtain glutamic acid crystals and secondary mother liquor, and Glutamic acid cryst...

Embodiment 2

[0044] A production process for refined glutamic acid, comprising the steps of:

[0045] Use a high-speed disk separator to separate the glutamic acid feed liquid and cell protein in the fermentation broth, and remove the fermentation cells. The speed of the high-speed disk separator to separate the cell protein is 5000r / min;

[0046]The glutamic acid feed liquid is pumped into the decolorization tank for decolorization treatment. Powdered activated carbon accounting for 2% of the glutamic acid feed liquid mass is added to the decolorization tank. The temperature in the decolorization tank is controlled at 50°C. After decolorization for 30 minutes, it is concentrated. The concentration parameters It is: temperature 70°C, vacuum degree -0.1kpa, primary crystallization to obtain glutamic acid crude crystals and primary mother liquor; crude crystals for decolorization, separation and iron removal, secondary crystallization to obtain glutamic acid crystals and secondary mother liqu...

Embodiment 3

[0057] The effect test of biological preparation of the present invention:

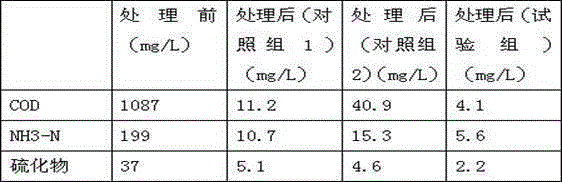

[0058] The experiment was carried out with glutamic acid fermented yeast liquid as the treatment sample.

[0059] Control group 1: use sawdust carrier; the type of microorganisms is the same as that of the test group; treatment method: after three days of continuous dosing, 5g / m3 per day, and then stand for six days, the detection and treatment results are shown in Table 1.

[0060] Control group 2: The carrier is the same as in Example 2, the difference is that only four kinds of bacteria are added, but Scenedesmus obliques is not added; treatment method: add 5g / cubic meter on the first day, and then leave it for six days to detect See Table 1 for the processing results.

[0061] Test group: the process of Example 2 of the present invention, the results of detection and treatment are shown in Table 1.

[0062] Table 1

[0063]

[0064] Conclusion: The carrier prepared by the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com