A salt-resistant superabsorbent resin

A technology of superabsorbent resin and salt resistance, applied in the field of functional polymer materials, can solve problems such as difficult to control product structure distribution, difficult to obtain, high polymer molecular weight, etc., to save preparation costs, increase osmotic pressure difference, The effect of improving salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

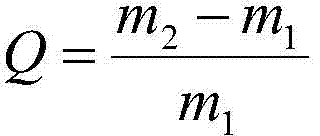

Method used

Image

Examples

Embodiment 1

[0024] 1) Dissolve 6.0 g of sodium polyacrylate, 2.5 g of poly-N-vinylpyrrolidone and 1.5 g of polyvinylsulfonic acid in 190 g of water, and dissolve them completely under stirring to obtain mixed solution A.

[0025] 2) 0.09g of crosslinking agent 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide and 0.9g of sodium chloride were dissolved in 29.01 g of water to obtain mixed solution B; step 1) The obtained mixed solution A and mixed solution B were added to 230 g of oil phase castor oil, and 1.15 g of emulsifier Tween-80 was added at the same time, and the mixture was stirred and reacted at a speed of 300 rpm at 60° C. for 5 hours.

[0026] 3) Finally, add precipitant ethanol to the reaction system to precipitate the product, filter, wash and filter the product with precipitant ethanol, filter again and dry to obtain the final product.

Embodiment 2

[0028] 1) Dissolve 8.0g of sodium polyacrylate, 4.8g of polyacrylamide and 3.2g of poly-2-hydroxy-3-acryloyloxypropanesulfonate potassium in 184g of water, and dissolve it completely under stirring , to obtain mixed solution A.

[0029] 2) Dissolve 0.2 g of crosslinking agent epichlorohydrin and 1.0 g of sodium sulfate in 18.8 g of water to obtain mixed solution B; add mixed solution A and mixed solution B obtained in step 1) to 330 g of oil phase paraffin oil , while adding 3.3 g of emulsifier sodium dodecylsulfonate, stirring and reacting at 50° C. at a speed of 200 rpm for 3 hours.

[0030] 3) Finally, a precipitant acetone is added to the reaction system to precipitate the product, filtered, and the filtered product is washed with the precipitant acetone, filtered again and dried to obtain the final product.

Embodiment 3

[0032] 1) Dissolve 22.5 g of polyglutamic acid, 9.0 g of poly N-vinyl caprolactam and 13.5 g of polyvinyl phosphoric acid in 255 g of water, and dissolve them completely under stirring to obtain mixed solution A.

[0033] 2) Dissolve 2.0 g of crosslinking agent aluminum chloride and 1.2 g of sodium phosphate in 16.8 g of water to obtain mixed solution B; add mixed solution A and mixed solution B obtained in step 1) to 747 g of oil phase rapeseed oil , while adding 24.9 g of emulsifier lecithin, stirring and reacting at a speed of 500 rpm at 60° C. for 1 hour.

[0034] 3) Finally, add precipitant isopropanol to the reaction system to precipitate the product, filter, wash and filter the product with precipitant isopropanol, filter again and dry to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com