Electromagnetic heat energy generation metal material applied to electric water dispenser

A technology of metal materials and water dispensers, which is applied in the direction of induction heating, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of heating efficiency and magnetization efficiency attenuation, and achieve good electrothermal performance and electromagnetic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

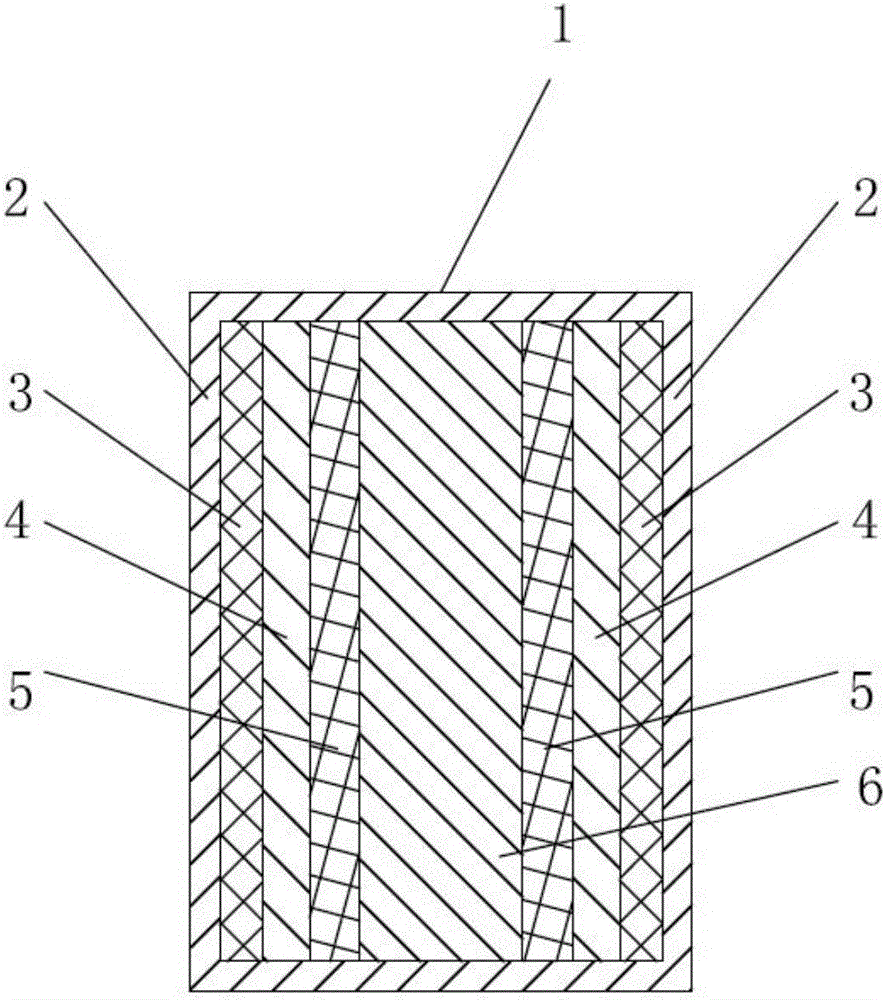

Image

Examples

Embodiment 1

[0029] A metal material used for generating electromagnetic heat energy of an electric water dispenser, comprising the following components by weight percentage: 1.8% carbon, 0.8-0.9% silicon, 8.0% manganese, 1.2% nickel, 0.13% copper oxide, trioxide 1% iron, 12.0% chromium, 0.02% gold, 0.1% boron, 0.31% tantalum, 0.25% titanium, 0.05% ruthenium, and the balance is iron and unavoidable impurities.

Embodiment 2

[0031] A metal material used for generating electromagnetic heat energy of an electric water dispenser, comprising the following components by weight percentage: 2.1% carbon, 0.8-0.9% silicon, 5.0% manganese, 1.5% nickel, 0.08% copper oxide, trioxide 3% iron, 8.0% chromium, 0.05% gold, 0.05% boron, 0.34% tantalum, 0.15% titanium, 0.07% ruthenium, and the balance is iron and unavoidable impurities.

Embodiment 3

[0033] A metal material used for generating electromagnetic heat in an electric water dispenser, comprising the following components by weight percentage: 2.1% carbon, 0.8-0.9% silicon, 6.0% manganese, 1.2-1.5% nickel, 0.09% copper oxide, four Ferric oxide 3%, chromium 11.0%, gold 0.04%, boron 0.08%, tantalum 0.33%, titanium 0.15-0.25%, ruthenium 0.06%, and the balance is iron and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com