Method for promoting dispersion phases in incompatible polymer blend to form stable fibers

A polymer, dispersed phase technology, applied in the direction of conjugated synthetic polymer rayon, fiber chemical characteristics, conjugated rayon, etc., can solve the problems of environmental pollution, high cost, long cycle, etc. performance, reducing dosage, promoting improved effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

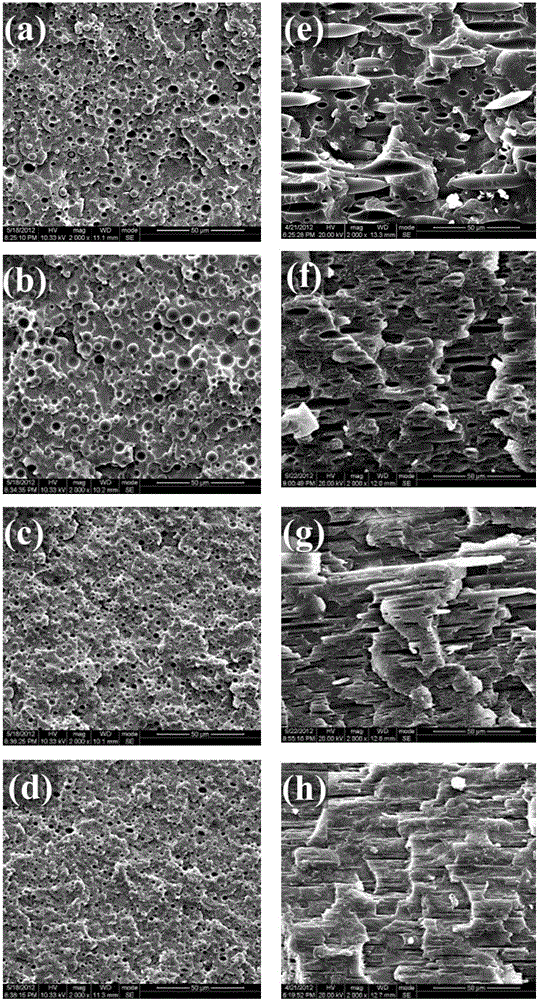

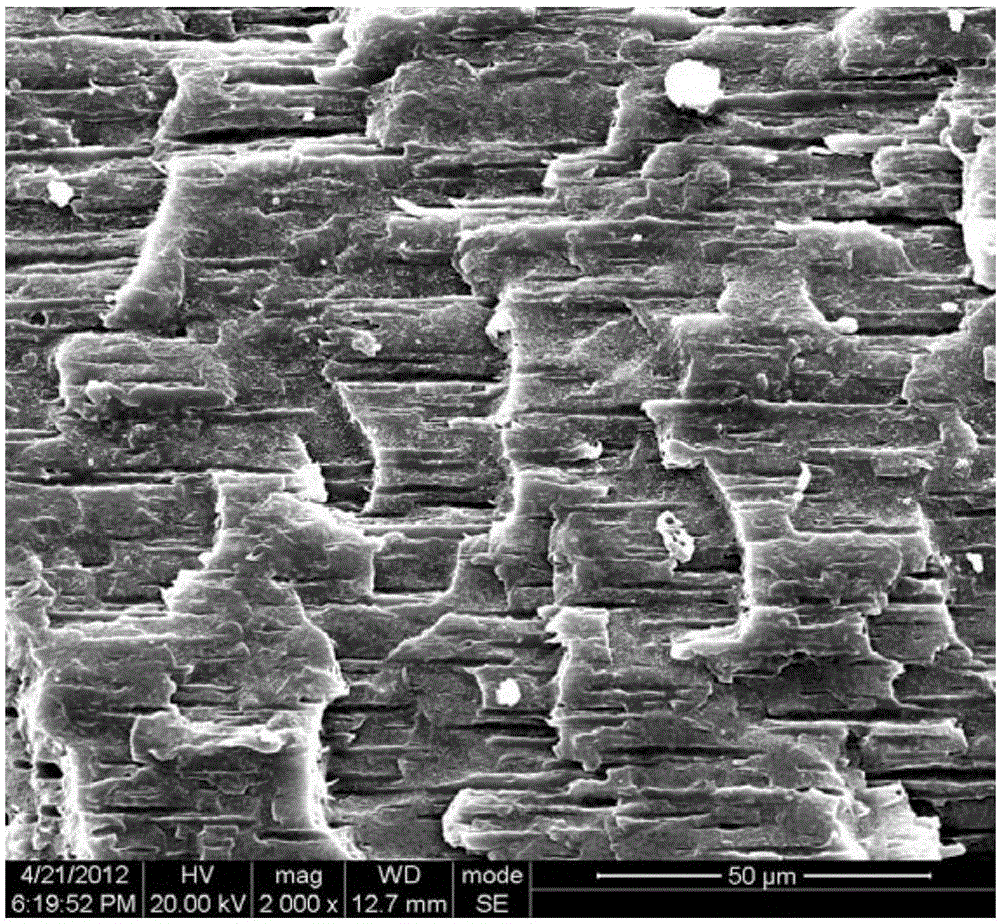

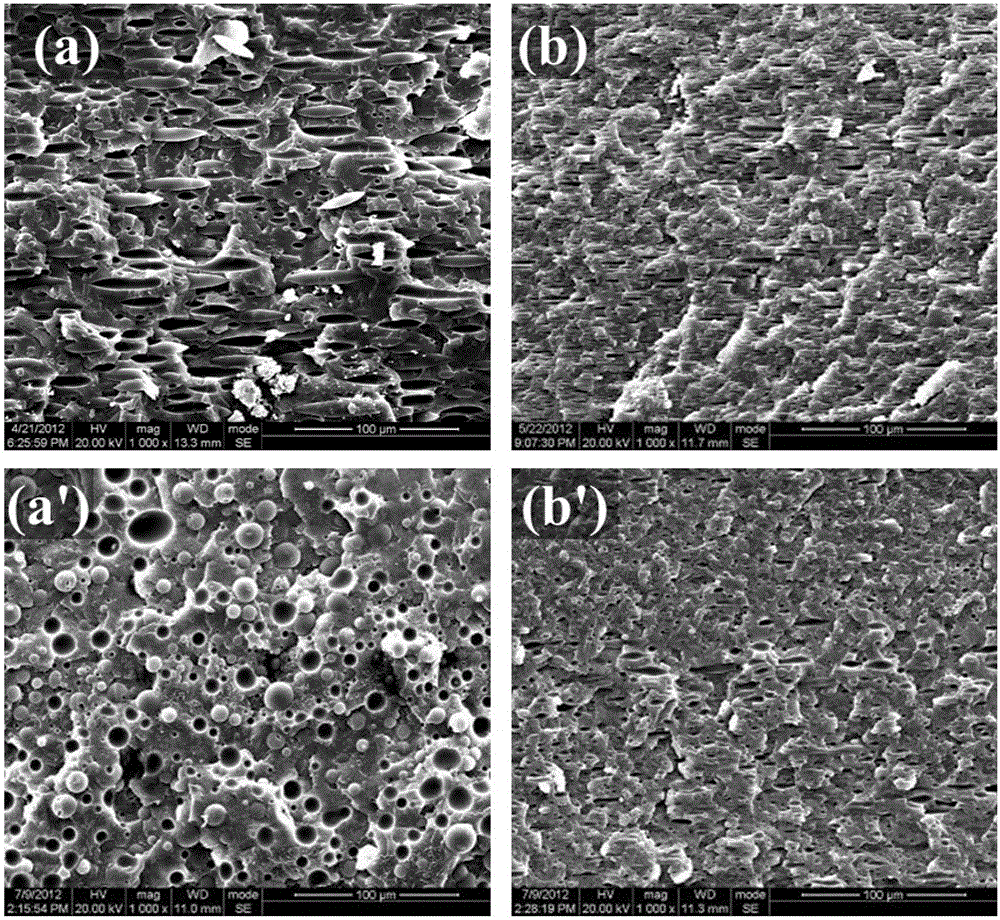

[0052] Formation of PP microfiber phase in the hydrophobic nano-silica / PP / PS blend system of embodiment 1

[0053] Select two mutually incompatible polymers PS and polymer PP respectively, wherein the grade of PS is: Taihua General (Ningbo) GP5250, the grade of PP is: Lanzhou Petrochemical T30S; the inorganic filler particles are hydrophobic nano-scale dioxide Silicon, the grade is DegussaAEROSILR974.

[0054] The dispersed phase polymer PP, the matrix phase polymer PS and the hydrophobic nano-scale silica particles were melt-blended at 200°C for 10 minutes using an internal mixer to prepare a blended compound. Sample preparation was performed by compression molding at 200°C and 10MPa, and then the PS / PP / silica blend composite system was applied with a stretching flow field at a stretching rate of 0.01s -1 , when stretched to a tensile strain of 1, the sample was rapidly cooled with liquid nitrogen, and the stretched sample was quenched in liquid nitrogen for 30 minutes and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com