A kind of anti-freezing rain cable material and the cable prepared therefrom

A technology of anti-freezing rain and cables, applied in the direction of cable/conductor manufacturing, insulated cables, power cables, etc., can solve problems such as tower collapse, cable grid hazards, economic losses, etc., to avoid excessive loads and solve the problem of easy freezing , to ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of single-core cables

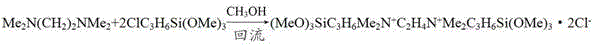

[0034] Preparation of antifreeze rain liquid: Take 1mol of tetramethylethylenediamine and 2mol of chloropropyltrimethoxysilane, dissolve them in methanol, and reflux at 60-65°C for 2 hours to prepare cationic quaternary ammonium salt; take the above 100 parts by weight of the prepared cationic quaternary ammonium salt, 60 parts by weight of ethyl acetate, and 40 parts by weight of ethylene glycol monobutyl ether were mixed at room temperature and sealed for later use.

[0035] Preparation of cables: After removing surface dirt and drying conductive metal wires (such as copper wires, copper-aluminum alloy wires, etc.), they are bundled or twisted to make a single conductor, and the single conductor is placed in a glass fiber sleeve. Repeatedly soak in liquid silica gel for many times, after curing and drying; inject a layer of methyl vinyl silicone rubber on its surface, wherein the injection molding temperature is 160-170°C, and then ...

Embodiment 2

[0037] Preparation of multi-core cables

[0038] The preparation method of the multi-core cable described in Example 2 is basically the same as that of the single-core cable described in Example 1, except that the glass fiber sleeve described in Example 1 only contains a single conductor, However, the glass fiber casing in Embodiment 2 contains three conductors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com