A preparation method of surface modified composite material for bone repair

A technology of surface modification and composite materials, which is applied in the field of polymer materials and biomaterials, can solve the problems of easy peeling off of the coating layer, cumbersome process, and limited depth, and achieve rapid mineralization ability, mild method, and good biocompatibility The effect of sexual biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, the preparation of polylactic acid-polyethylene glycol-polylactic acid copolymer matrix material

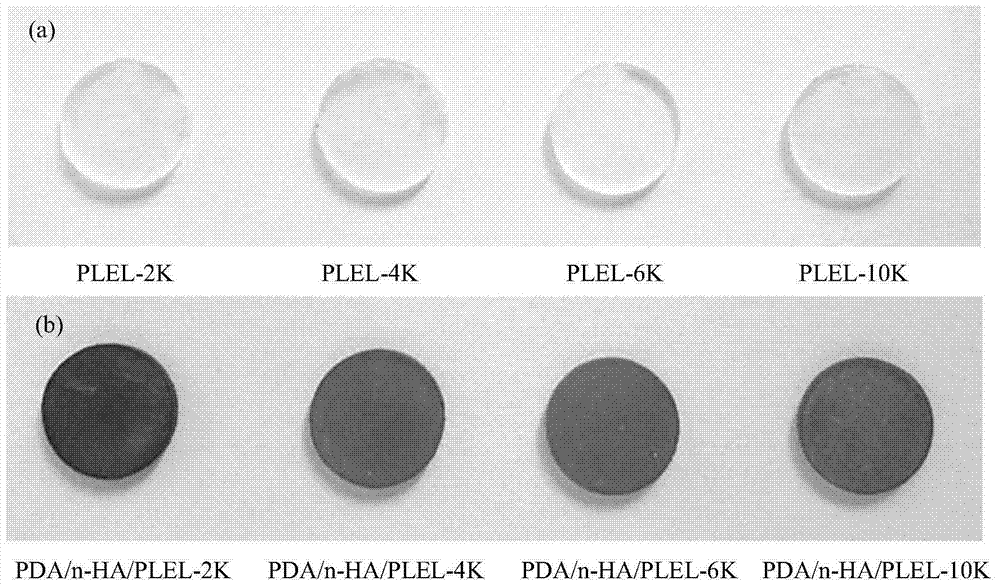

[0014] Weigh 6g of recrystallized L-lactide (L-LA), add 0.176g of macromolecular initiator polyethylene glycol (Mn=2,000) into a three-necked flask, protect with nitrogen, and dissolve 0.0185g of stannous octoate After the reaction is completed, the product is dissolved in dichloromethane, precipitated with ethanol, purified repeatedly three times, and then obtained by vacuum drying. The white solid is PLA-PEG(2,000)-PLA block (PLEL) copolymer, referred to as PLEL-2K. Put the synthesized PLEL copolymers into Φ8mm×1mm stainless steel molds, preheat the molds filled with raw materials in a flat vulcanizer at 175°C for 5min, and at the same temperature, press 10MPa positive pressure for 5min to prepare PLEL Matrix material.

Embodiment 2

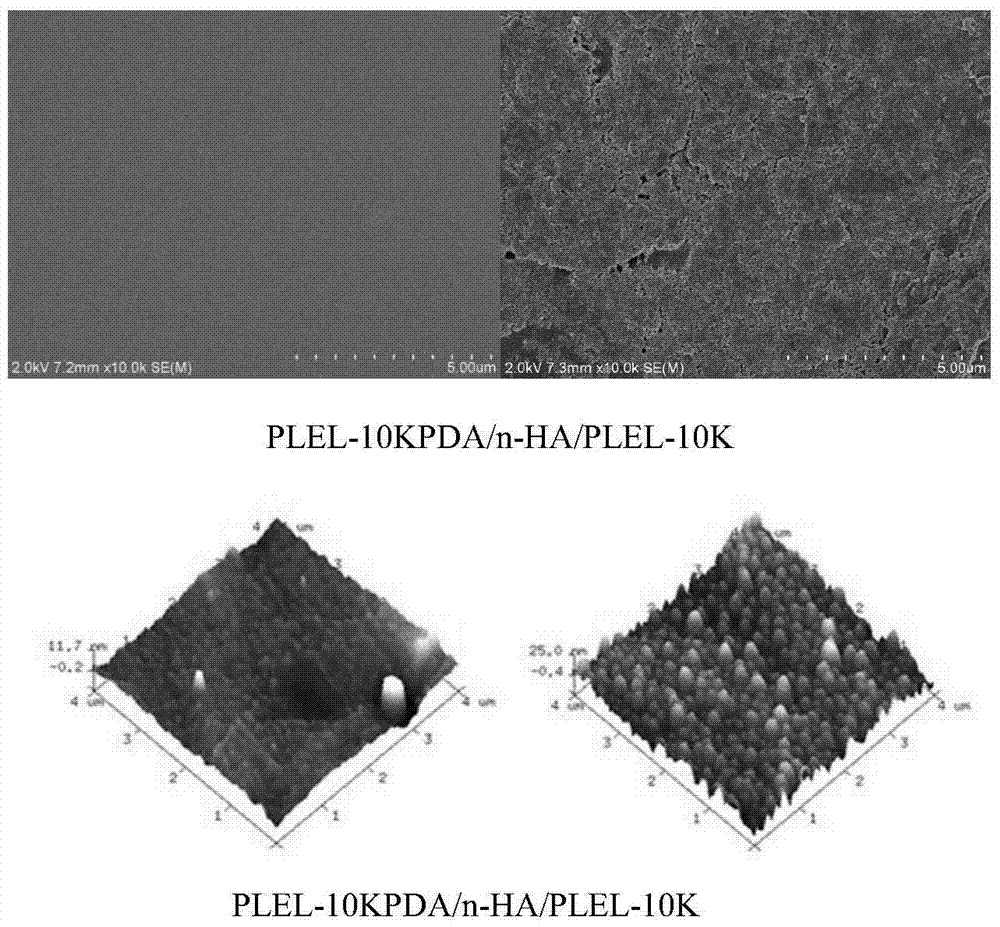

[0015] Embodiment 2, the preparation of surface modified composite material

[0016] Dopamine hydrochloride was dissolved in 10mM Tris·HCl buffer solution (pH=8.5) to a concentration of 4 mg / mL, while nano-hydroxyapatite (n-HA) was dispersed in the same buffer solution at the same concentration as 4mg / mL. Mix the two solutions in equal volumes, and finally immerse the PLEL matrix material ultrasonically washed with ultrapure water into the mixed solution, and react for 24 hours in a water bath constant temperature oscillator at 25°C for surface coating; after the reaction, take out the PLEL matrix material and use Ultrapure water ultrasonic washing three to four times, vacuum drying at 40 ℃ for 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com