Chelate fiber, synthetic method thereof and method for enriching hexavalent chromium from serpentine

A technology of chelating fibers and synthesis methods, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve environmental pollution, unusable problems, etc., achieve low price, overcome poor adsorption performance , The effect of short adsorption equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

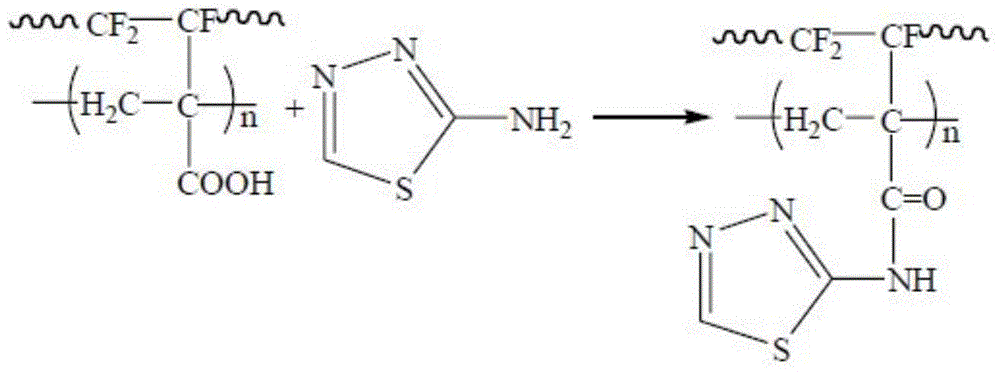

[0030] A kind of synthetic method of chelating fiber MATF, carries out following steps successively:

[0031] 1) Put about 20.0mg of the matrix---grafted acrylic polytetrafluoroethylene fiber (PTFE-g-AA) into a 100mL three-necked bottle, add 50mL of toluene and soak for 12 hours;

[0032] Remarks: Grafted acrylic polytetrafluoroethylene fiber (PTFE-g-AA) is also known as polytetrafluoroethylene grafted acrylic copolymer, acrylic modified polytetrafluoroethylene fiber, etc. The PTFE-g-AA functional group (that is, -COOH) content in the grafted acrylic polytetrafluoroethylene fiber (PTFE-g-AA) is 3.07mmol / g;

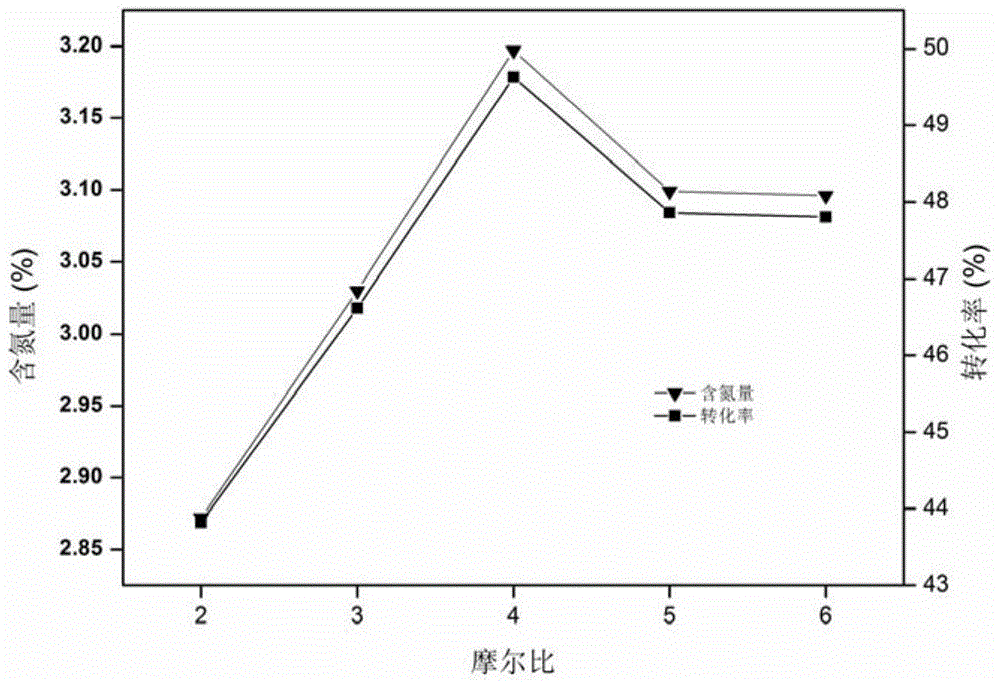

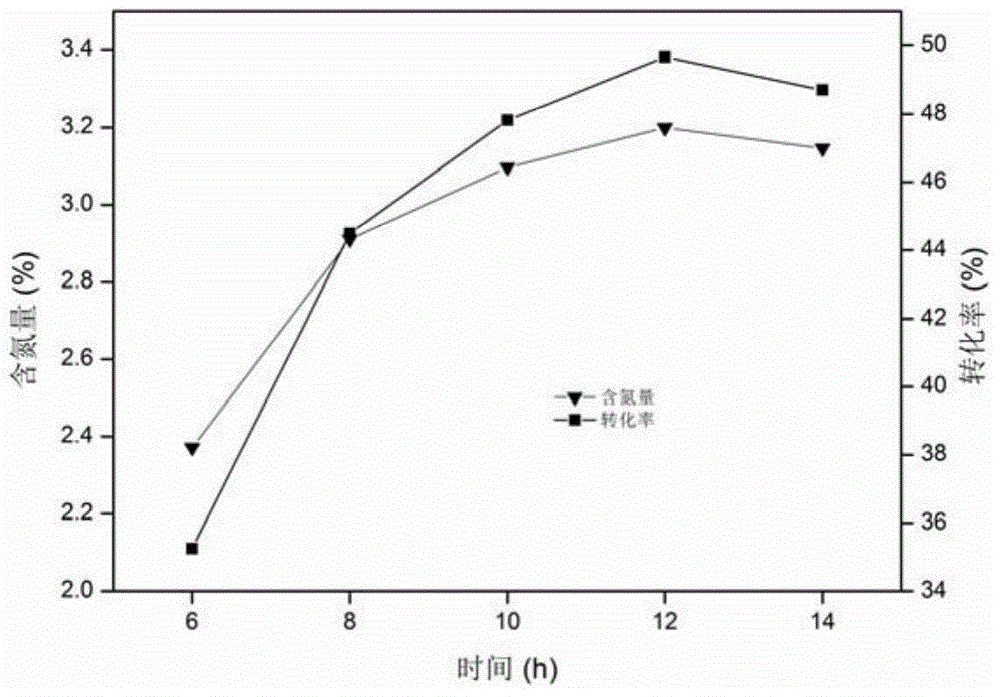

[0033] 2), then add 0.246mmol of the ligand-2-amino-1,2,4-thiadiazole (MAT) into the three-necked flask (that is, the reaction molar ratio of PTFE-g-AA and the ligand is 1 : 4), 35 DEG C of stirring reaction 12 hours, the stirrer rotating speed is 300rpm / min;

[0034] 3), the product obtained in step 2) is filtered, and the obtained filter cake is washed 3 times successi...

Embodiment 2

[0085] The serpentine mineral powder that was ball-milled for 1 hour was refluxed at 100°C for 1 hour with 3mol / L HCl at a solid-to-liquid ratio of 1:4, filtered and separated, and the filtrate was leached with fresh mineral powder to reduce acidity; fresh mineral powder was used for leaching Acid reduction, on the one hand, can adjust the pH value of the acid leaching solution to the range suitable for fiber adsorption of Cr(VI), which is conducive to separation and enrichment; on the other hand, it can increase the concentration of Cr(VI) ions in the acid leaching solution, and improve The efficiency of the separation and enrichment process; after that, the fiber adsorption technology is used to separate and enrich the Cr(VI) ions in the pickling solution, where the volume of the pickling solution (L): MATF fiber mass (g) = 1:1. Among them, the fiber adsorption technology is to use the adsorption material to adsorb the adsorbate. Adsorption materials commonly used in fiber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com