Glass wool with nano-particle layer

A technology of nano-particles and glass wool, which is applied in the field of thermal insulation materials, can solve problems such as unfavorable social sustainable development, lack of suitable materials for thermal insulation, and long-term planning and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] nano-SiO 2 , has the following basic properties: the specific surface area is 200±25m 2 / g; loss on drying is 1% (drying at 100°C for 2h); loss on ignition is 4% (burning at 1000°C for 2h); purity is 99.8%; pH value of suspension is 3.7~4.7 (4% water suspension Turbid liquid); the bulk density is 50g / L; the particle size range is 10nm to 20nm; the average particle size is about 15nm.

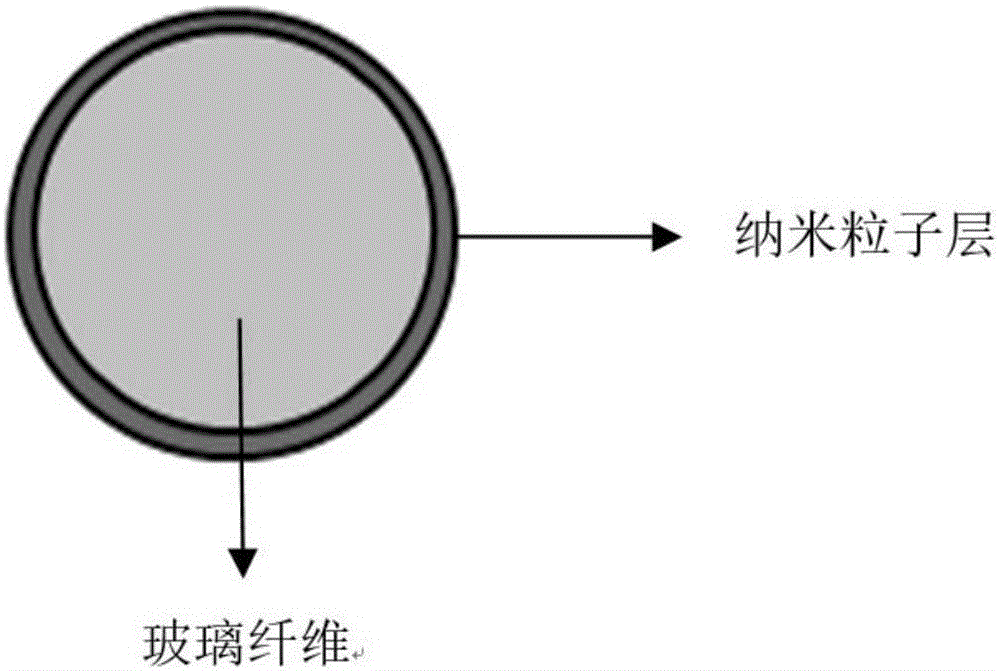

[0096] nano-SiO 2 Add it into 73g of the above-mentioned glass fibers, and stir at a speed of 100r / min for 1 hour, so that the nanoparticles are uniformly attached to the surface of the glass fibers, and a composite of nanoparticles and glass fibers is obtained.

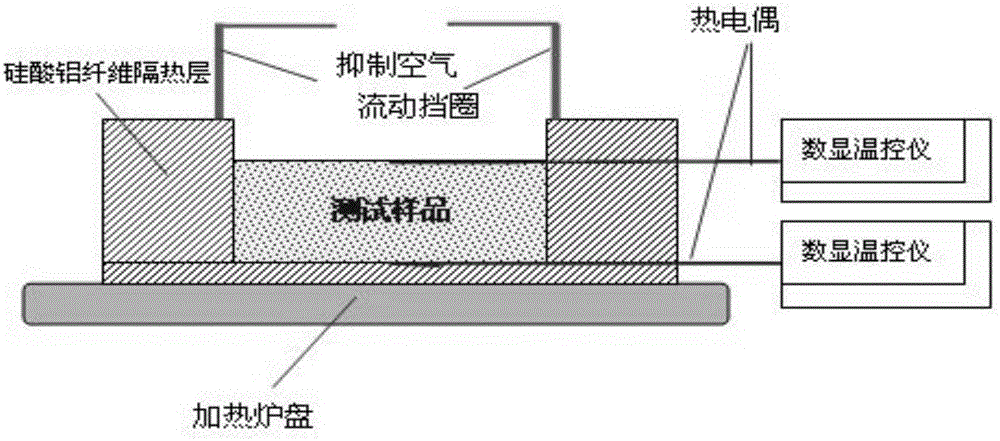

[0097] Spray 8g of acrylic resin binder (provided by the factory for direct spraying) into the composite of the above-mentioned nanoparticles and glass fibers, and then put it into a mold and use a YES-300 pressure testing machine for compression molding. During the pressing process, the pressure was first applied slowly by c...

Embodiment 2

[0100] In addition to adding half the amount of nano-SiO 2 , and nano-SiO 2 Except for the same amount of silicon carbide (with a particle size ranging from 2 μm to 4 μm; the average particle size is about 3 μm), the glass wool with nanoparticle layer of the present invention was prepared by the same method as in Example 1. The thickness of the nanoparticle layer is 1 / 33 of the diameter of the glass fiber.

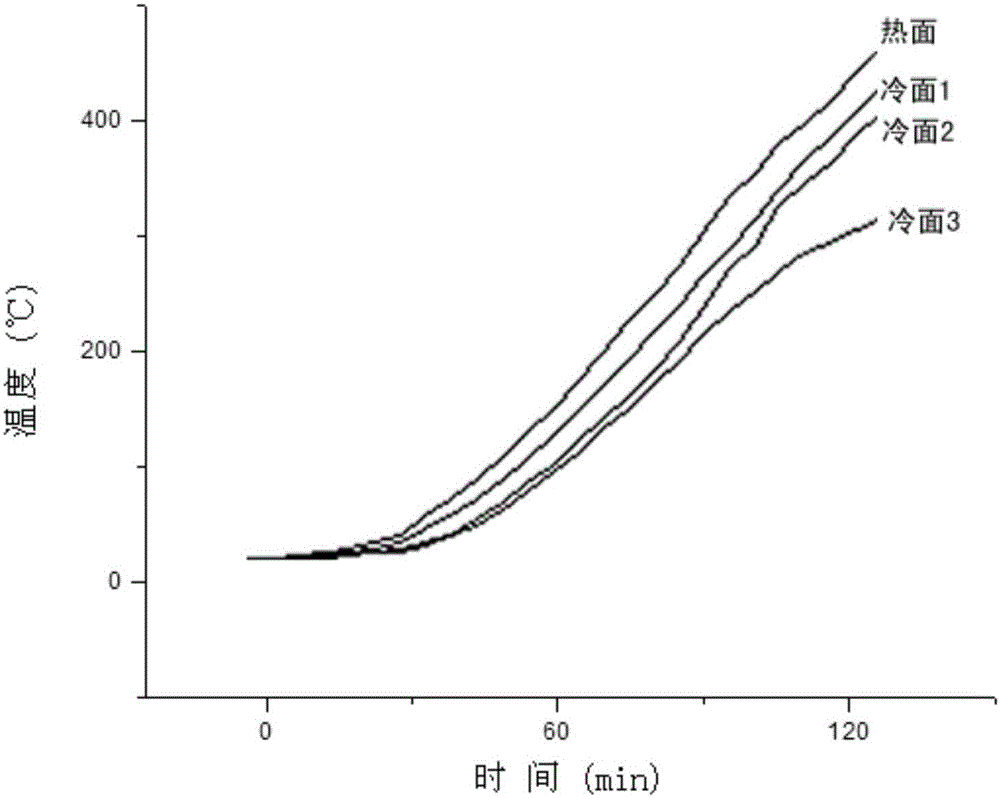

[0101] The results of the back temperature test were as follows: image 3 shown. It can be seen that the maximum temperature difference between the hot surface and the cold surface 3 of the glass wool is 121 degrees, and the gap tends to widen.

Embodiment 3

[0103] In addition to adding half the amount of nano-SiO 2 , and nano-SiO 2 Equal amount of silicon carbide (particle size range is 2μm ~ 4μm; average particle size is about 3μm), nano-SiO 2 1 / 10 of the amount of nano-Al 2 o 3 (The average particle diameter is about 30nm~about 50nm), adopt the same method as Example 1 to prepare the glass wool with the nanoparticle layer of the present invention. The thickness of the nanoparticle layer is 1 / 33 of the diameter of the glass fiber.

[0104] The results of the back temperature test show that the thermal insulation effect of the glass wool is better than that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com