Ceramic-polymer composite material, preparation method therefor and use thereof

A composite material and polymer technology, applied in the direction of fixed capacitor dielectric, fixed capacitor components, etc., can solve the problems of low dielectric constant temperature coefficient, circuit performance deterioration, and can not be used as the performance basis of microwave frequency band, etc., to achieve low dielectric Effects of Loss and Microwave Dielectric Properties Optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

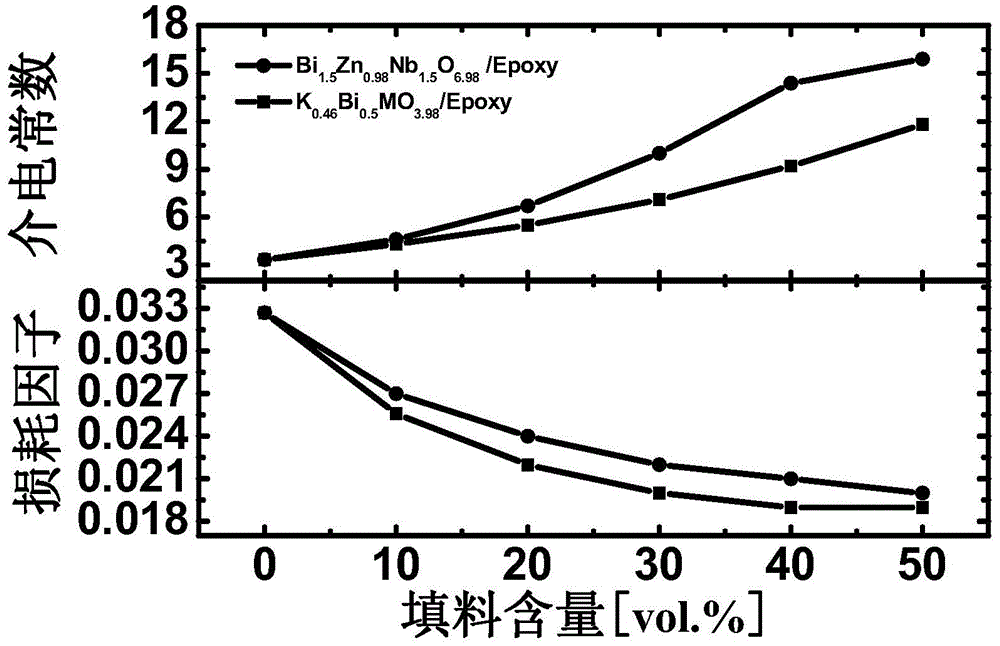

Examples

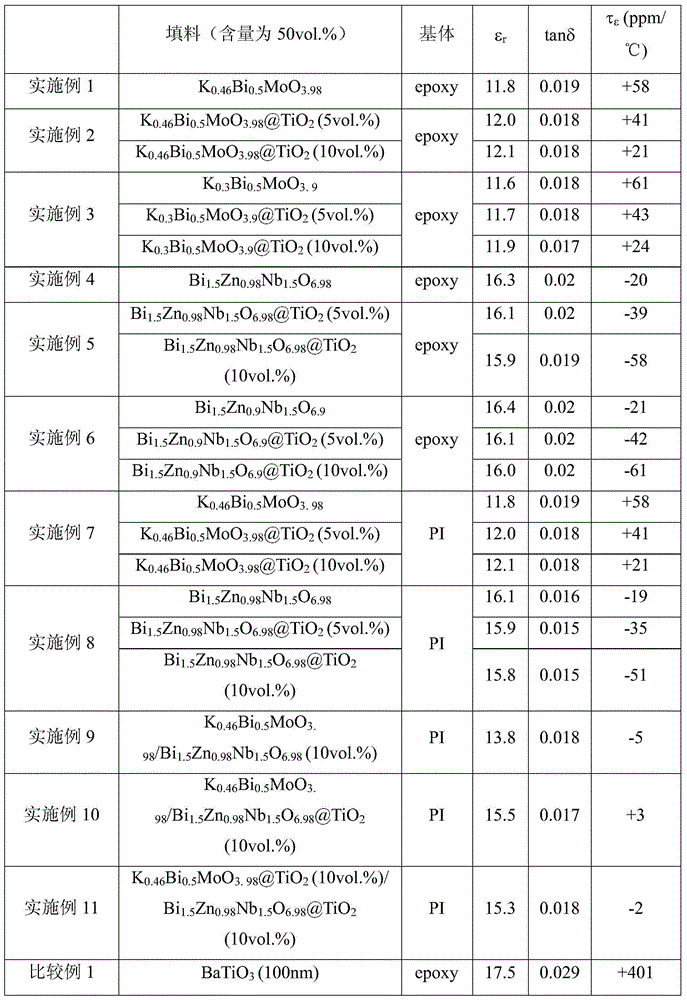

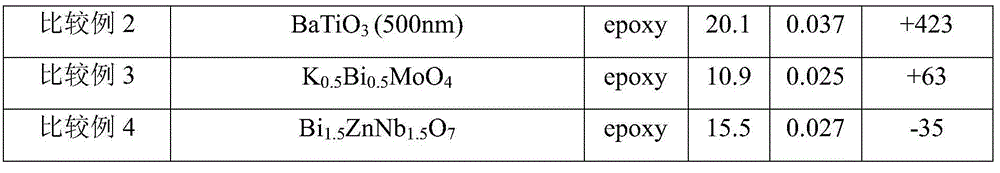

Embodiment 1

[0074] According to K 0.46 Bi 0.5 MoO 3.98 Molecular formula weighs raw material K 2 CO 3 、 Bi 2 o 3 、MoO 3 , the raw materials are mixed evenly by planetary ball milling method, the rotating speed is 160rpm, and the time is 3-4 hours. The homogeneously mixed slurry was dried, placed in an alumina crucible, and calcined at 550°C±30°C for 2 hours. The calcined powder is pulverized and dried by planetary ball milling, and then calcined at 630°C±30°C for 2 hours to obtain K 0.46 Bi 0.5 MoO 3.98 Ceramic powder. The ceramic powder prepared above was mechanically crushed and passed through a 120-mesh sieve, and then further crushed by planetary ball milling for 8 hours. Place the pulverized ceramic powder in an alumina crucible and treat it at 580°C±30°C for 2 hours, and cool naturally to obtain the required K 0.46 Bi 0.5 MoO 3.98 Ceramic powder. Will K 0.46 Bi 0.5 MoO3.98 The ceramic powder is mixed with the epoxy glue according to the corresponding ratio, and the ...

Embodiment 2

[0078] Prepare K according to the method described in Example 1 0.46 Bi 0.5 MoO 3.98 For ceramic powder, add ceramic powder to ethanol solvent at a volume ratio of 20:100, and add PVP dispersant accounting for 3% of the mass of ceramic powder, stir until PVP is completely dissolved, and ultrasonically treat for 1 hour to obtain ceramic powder Body suspension; Ultrasonic the mixed solution of titanium isopropoxide (TIPP) in acetylacetone for 15 minutes, ultrasonic the mixed solution of titanium isopropoxide (TIPP) in acetylacetone for 15 to 20 minutes, then add the above ceramic powder suspension In the turbid solution, stir at a speed of 500rpm for 10 minutes, then change to a speed of 300rpm, heat up to 70°C for 12 hours, centrifuge the product after the reaction, and use a mixture of ethanol and acetone with a volume ratio of 1:1 , ethanol and distilled water for 3 times and dried in a vacuum at 60°C, put the dried product in a muffle furnace and raise the temperature to 6...

Embodiment 3

[0083] According to K 0.3 Bi 0.5 MoO 3.9 Molecular formula weighs each raw material K 2 CO 3 、 Bi 2 o 3 、MoO 3 , and prepare K according to the method described in Example 1 0.3 Bi 0.5 MoO 3.9 Ceramic powder, wherein the calcination and firing temperatures are 550°C±30°C and 640°C±30°C respectively. According to the method described in Example 1, the ceramic powder was pulverized and spheroidized, and the heat treatment temperature was 590°C±30°C.

[0084] Prepare K according to the method described in Example 1 0.3 Bi 0.5 MoO 3.9 TiO 2 Core-shell structure ceramic powder, in which TiO 2 The volume fractions are 5% and 10%, respectively.

[0085] The above-prepared K 0.46 Bi 0.5 MoO 3.98 Ceramic powder and K 0.3 Bi 0.5 MoO 3.9 TiO 2 The core-shell structure ceramic powder was mixed with epoxy glue at a volume fraction of 50%, and a composite material thick film was prepared according to the method described in Example 1. The microwave dielectric properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com