A spherical polyelectrolyte brush dual-element retention aid system and method for improving pulp retention

A technology of polyelectrolyte brush and retention rate, which is applied in the field of papermaking industry, can solve the problems of poor shear resistance and achieve the effects of strong shear resistance, less additive dosage and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

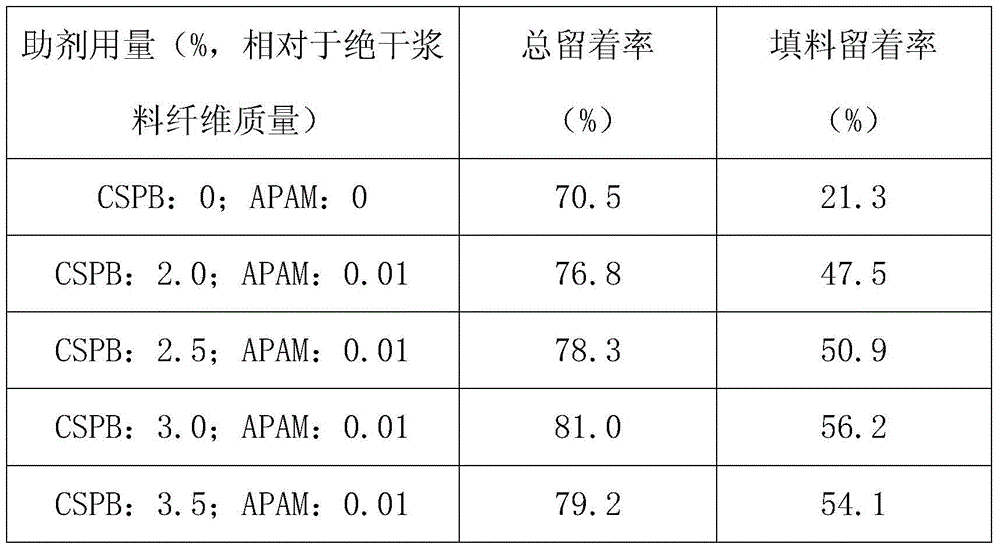

[0030] Disperse the eucalyptus pulp fiber in water with a beating degree of 25°SR, and then uniformly mix it with precipitated calcium carbonate whose mass percentage is 10% relative to the dry eucalyptus pulp fiber to obtain a slurry. At a stirring speed of 600rpm, a cationic spherical polyelectrolyte brush of 2.0 to 3.5% relative to the dry eucalyptus pulp fiber mass percentage is added, and the inner core of the cationic spherical polyelectrolyte brush is SiO 2 The particle size is 60nm, the molecular weight of the brush layer is 71300g / mol, and the charge density is 250μeq / g; after 60 seconds, add anionic polyacrylamide (6 million molecular weight) that is 0.01% relative to the absolute dry eucalyptus pulp fiber mass percentage, and continue After stirring for 60 seconds, open the drain valve, take the filtrate of the first 100ml, and measure the total retention rate of the slurry and the filler retention rate as shown in Table 1.

[0031] Table 1 Effect of CSPB / APAM dual ...

Embodiment 2

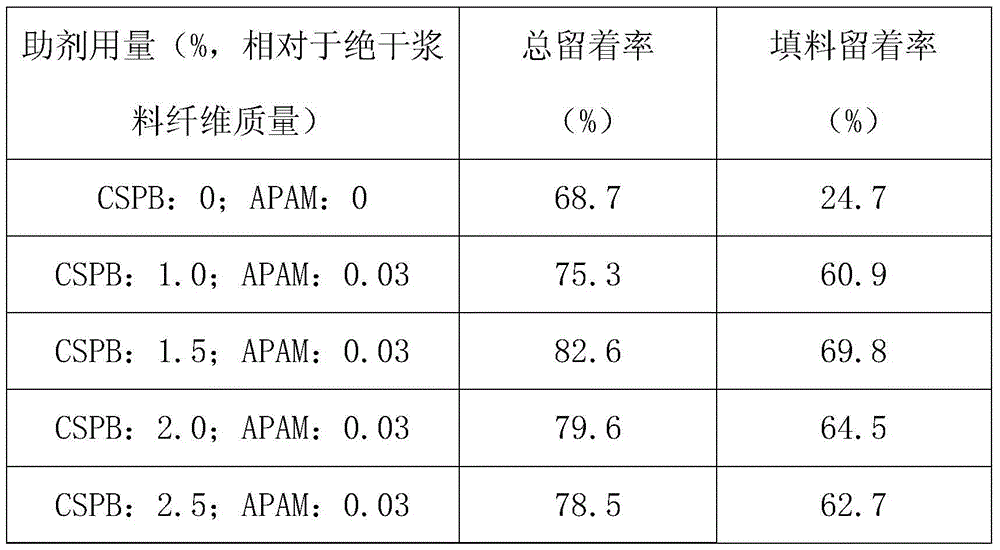

[0034] Disperse reed pulp fibers in water with a beating degree of 33°SR, and then uniformly mix it with 10% chalk relative to the absolute dry reed pulp fiber mass percentage to obtain a slurry. At a stirring speed of 600rpm, a cationic spherical polyelectrolyte brush with a mass percentage of 1.0 to 2.5% relative to the dry reed pulp fiber is added, and the inner core of the cationic spherical polyelectrolyte brush is SiO 2 The particle size is 80nm, the molecular weight of the brush layer is 106700g / mol, and the charge density is 340μeq / g; after 60 seconds, add anionic polyacrylamide (6 million molecular weight) that is 0.03% relative to the absolute dry reed pulp fiber mass percentage, and continue stirring After 60 seconds, open the drain valve, get the filtrate of the first 100ml, and record the total retention rate of the slurry and the filler retention rate as shown in Table 2.

[0035] Table 2 Effect of CSPB / APAM dual system on the retention rate of reed pulp

[0036...

Embodiment 3

[0038] Disperse the eucalyptus pulp fiber in water with a beating degree of 44°SR, and then uniformly mix it with precipitated calcium carbonate whose mass percentage is 20% relative to the dry eucalyptus pulp fiber to obtain a slurry. At a stirring speed of 600rpm, a cationic spherical polyelectrolyte brush of 1.0 to 2.5% relative to the mass percentage of the dry eucalyptus pulp fiber is added, and the inner core of the cationic spherical polyelectrolyte brush is SiO 2 The particle size is 100nm, the molecular weight of the brush layer is 154900g / mol, and the charge density is 395.5μeq / g; after 60 seconds, add anionic polyacrylamide (8 million molecular weight) that is 0.02% relative to the absolute dry eucalyptus pulp fiber mass percentage, After continuing to stir for 60 seconds, open the drain valve, get the filtrate of the first 100ml, and record the total retention rate and filler retention rate of the slurry as shown in Table 3.

[0039] Table 3 Effect of CSPB / APAM dua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com