Sample pretreatment method simultaneously determining arsenic and mercury in milk and dairy products and detection method using same

A sample pretreatment and dairy product technology, applied in the preparation of test samples, fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of cost, manpower and material resources, etc., achieve accurate test results, save test costs, arsenic and The effect that the loss of mercury element is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

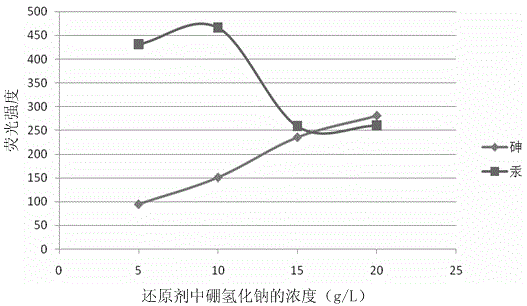

Method used

Image

Examples

Embodiment 1

[0022] 1 Main instruments and reagents.

[0023] 1.1 Instrument

[0024] Jitian Atomic Fluorescence Photometer; High Performance Arsenic Hollow Cathode Lamp; High Performance Mercury Hollow Cathode Lamp; American CEI Microwave Digestion Equipment.

[0025] 1.2 Reagents

[0026] Mercury standard stock solution: 1mg / L, National Center for Standard Materials; arsenic standard stock solution: 1mg / L, National Center for Standard Materials; Urea; saturated sodium hydroxide solution; all the utensils in the experiment were soaked in (1:1) nitric acid solution overnight, then rinsed with distilled water and ultrapure water, and then dried for later use; the water used in the experiment was ultrapure water (with a resistance value greater than 18.2MΩ).

[0027] 2 Instrument working conditions

[0028] Photomultiplier tube negative high voltage 240mV; mercury lamp current 30mA; arsenic lamp current 60mA; atomizer height 10mm carrier gas flow 400mL / min; shielding gas flow 1000mL / min;...

Embodiment 2

[0041] In this example, the sample pretreatment method is adjusted on the basis of Example 1, and the rest of the method steps are the same as in Example 1.

[0042]Sample pretreatment: Weigh the milk beverage to be tested in the digestion tank, the sampling volume is 1.0g, add 2mL hydrogen peroxide (30% by mass fraction) and 4mL nitric acid (65.0% to 68.0% by mass fraction) to obtain the Digestion solution: place the solution to be digested in the microwave digestion equipment, and digest it according to the set procedure (see Table 1 in Example 1). After the digestion is completed and cooled to 25-30°C, add 1.0mL saturated sodium hydroxide solution to obtain neutralization solution; transfer the neutralizing solution to a 25mL volumetric flask with a volume fraction of 5% hydrochloric acid solution, then add 2.5mL of 50g / L thiourea solution, and use a volume fraction of 5% hydrochloric acid solution to dilute to 25mL and mix to obtain Liquid to be tested. At the same time a...

Embodiment 3

[0045] In this example, the sample pretreatment method is adjusted on the basis of Example 1, and the rest of the method steps are the same as in Example 1.

[0046] Sample pretreatment: Weigh the milk powder of the sample to be tested in the digestion tank, the sampling volume is 0.3g, add 2mL of hydrogen peroxide (30% by mass fraction) and 4mL of nitric acid (65.0% to 68.0% by mass fraction) to obtain the digested solution; place the solution to be digested in the microwave digestion equipment, and digest it according to the set program (see Table 1 in Example 1). It is that 5% hydrochloric acid solution is transferred in the 25mL volumetric flask by neutralizing solution with volume fraction, then adds the thiourea solution of 2.5mL50g / L, is that 5% hydrochloric acid solution is settled to 25mL and mixes with volume fraction, obtains measuring liquid. At the same time as a blank control.

[0047] The correlation coefficients of the standard curve are: the correlation coef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com