High-performance miniature supercapacitor and fabrication method thereof

A supercapacitor, high-performance technology, applied in hybrid capacitor electrodes, hybrid capacitor current collectors, etc., can solve the problems of low utilization of electrode material surface area, small capacitance, etc., achieve good pseudocapacitance characteristics, improve energy density, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

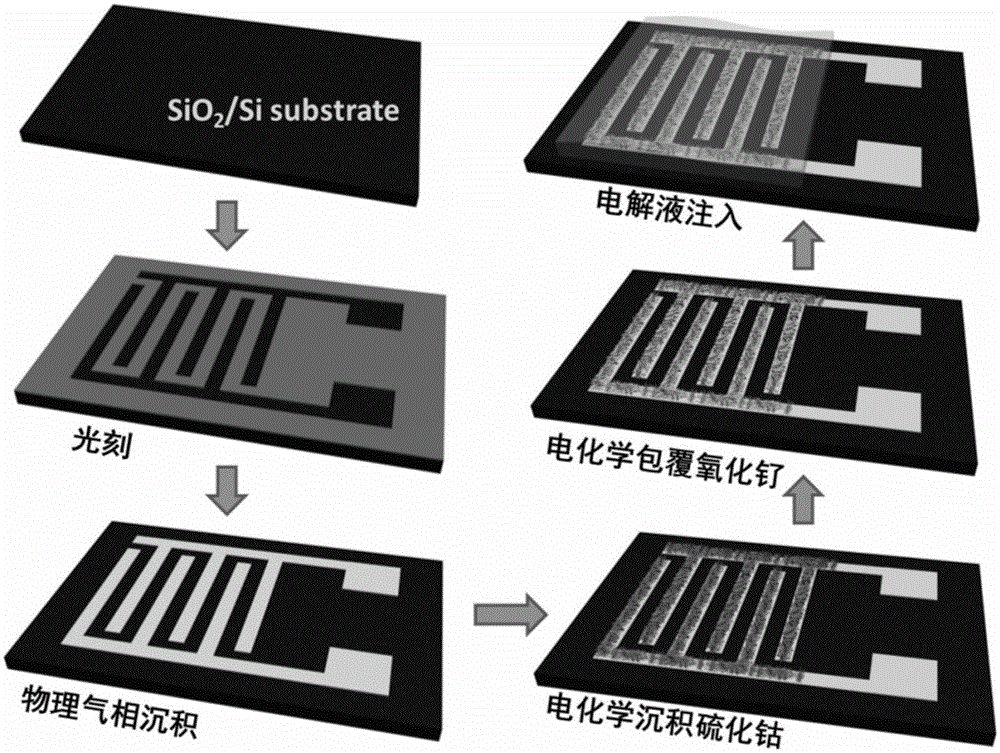

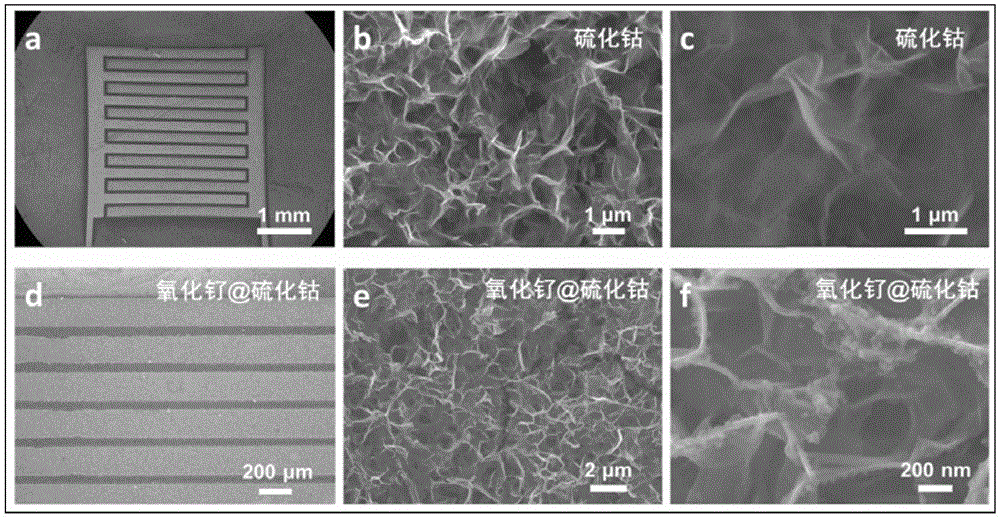

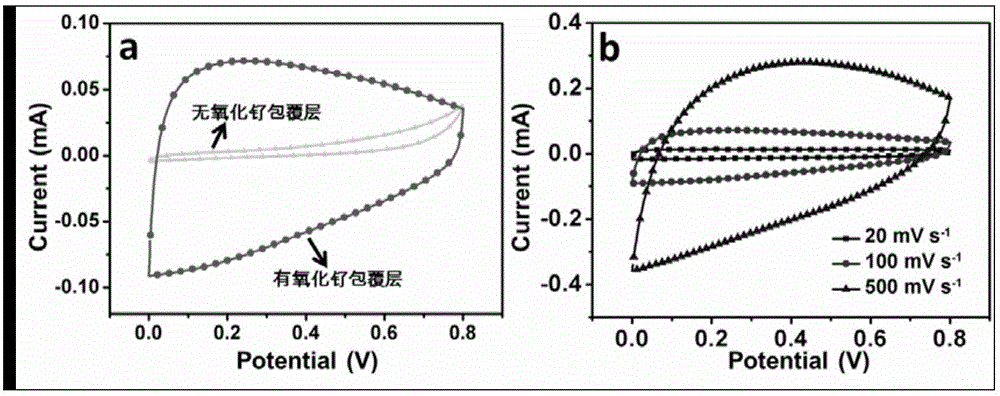

[0028] Such as figure 1 As shown, the preparation method of a high-performance miniature supercapacitor with a heterostructure of cobalt sulfide nanosheets modified by ruthenium oxide includes the following steps:

[0029] 1. Select the silicon substrate, cut the silicon substrate into an appropriate size, and then ultrasonically clean the silicon wafer with isopropyl alcohol (IPA) for about 3 minutes, and dry it with nitrogen;

[0030] 2. Use a spin coater to spin coat a layer of 9000A on the substrate. The spin coat speed is 4000r / min and the spin coat time is 40s. After homogenizing the glue, use an electric hot plate to bake at 100°C, 15min;

[0031] 3. Use a photolithography machine to etch the interdigital electrode pattern on the spin-coated silicon wafer, and the exposure time is 28s;

[0032] 4. Development: First immerse the photoetched substrate in RD6 developer solution for 90s, then put it in deionized water for 30s, then put it in the second part of deionized water for 30...

Embodiment 2

[0041] The preparation method of the high-performance miniature supercapacitor with the heterostructure of ruthenium oxide modified cobalt sulfide nanosheets includes the following steps:

[0042] 1. Select the silicon substrate, cut the silicon substrate into an appropriate size, and then ultrasonically clean the silicon wafer with isopropyl alcohol (IPA) for about 3 minutes, and dry it with nitrogen;

[0043] 2. Use a spin coater to spin coat a layer of 9000A on the substrate. The spin coat speed is 4000r / min and the spin coat time is 40s. After homogenizing the glue, use an electric hot plate to bake at 100°C, 15min;

[0044] 3. Use a photolithography machine to etch the interdigital electrode pattern on the spin-coated silicon wafer, and the exposure time is 28s;

[0045] 4. Development: First immerse the photoetched substrate in RD6 developer solution for 90s, then put it in deionized water for 30s, then put it in the second part of deionized water for 30s, and dry it with nitroge...

Embodiment 3

[0054] The preparation method of the high-performance miniature supercapacitor with the heterostructure of ruthenium oxide modified cobalt sulfide nanosheets includes the following steps:

[0055] 1. Select the silicon substrate, cut the silicon substrate into an appropriate size, and then ultrasonically clean the silicon wafer with isopropyl alcohol (IPA) for about 3 minutes, and dry it with nitrogen;

[0056] 2. Use a spin coater to spin coat a layer of 9000A on the substrate. The spin coat speed is 4000r / min and the spin coat time is 40s. After homogenizing the glue, use an electric hot plate to bake at 100°C, 15min;

[0057] 3. Use a photolithography machine to etch the interdigital electrode pattern on the spin-coated silicon wafer, and the exposure time is 28s;

[0058] 4. Development: First immerse the photoetched substrate in RD6 developer solution for 90s, then put it in deionized water for 30s, then put it in the second part of deionized water for 30s, and dry it with nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume specific capacity | aaaaa | aaaaa |

| Volume specific capacity | aaaaa | aaaaa |

| Volume specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com