HEMT device with junction type semiconductor layer

A semiconductor and junction technology, applied in the field of HEMT devices, can solve problems such as limiting gate voltage swing, and achieve the effects of increasing off-state breakdown voltage, improving electric field concentration effect, and uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

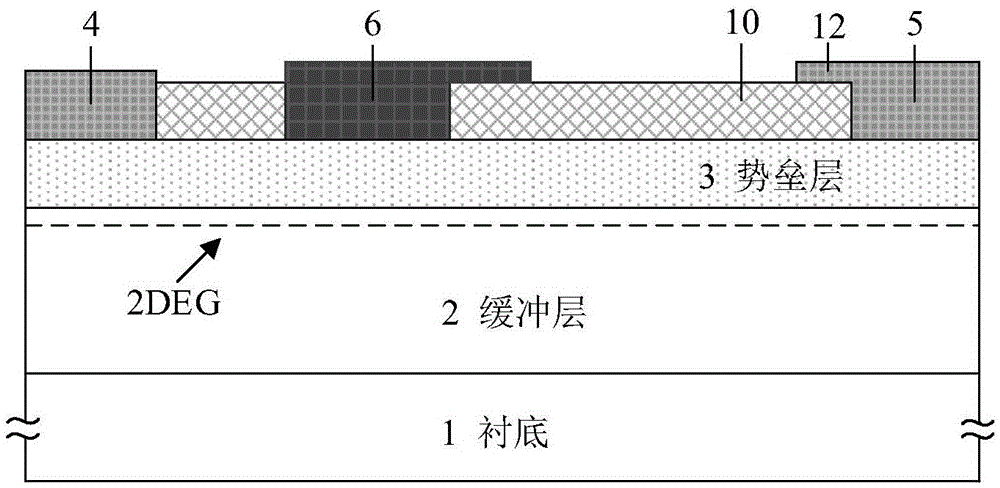

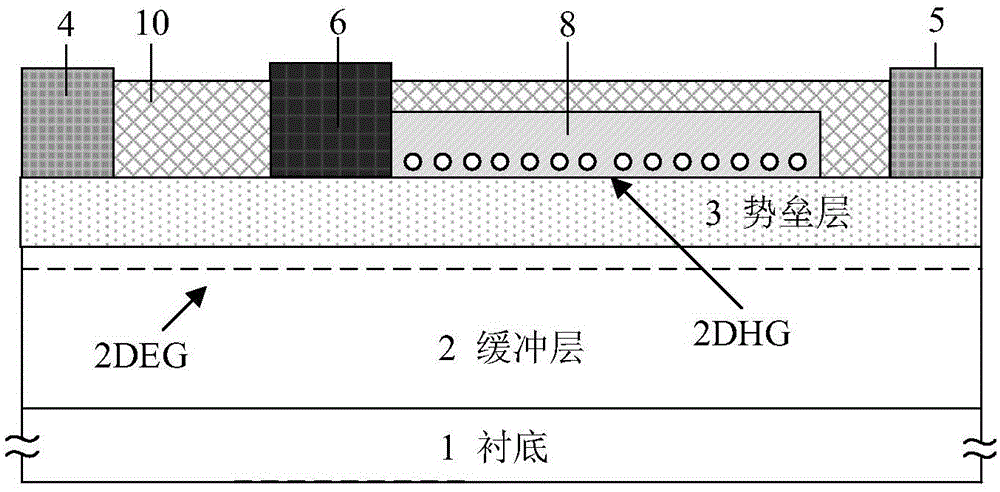

Embodiment 1

[0034] Such as Figure 4As shown, this example includes a substrate 1, a buffer layer 2 disposed on the upper surface of the substrate 1, and a barrier layer 3 disposed on the upper surface of the buffer layer 2, and the contact surface of the buffer layer 2 and the barrier layer 3 forms a The first heterojunction of a two-dimensional electron gas channel (2DEG); the two ends of the upper surface of the barrier layer 3 respectively have a source electrode 4 and a drain electrode 5, and the middle part of the upper surface of the barrier layer 3 has a gate structure; The upper surface of the barrier layer 3 between the source electrode 4 and the gate structure has a dielectric passivation layer 10, and the upper surface of the barrier layer 3 between the drain electrode 5 and the gate structure has a junction semiconductor layer 8; The contact surface between the junction semiconductor layer 8 and the barrier layer 3 forms a second heterojunction with two-dimensional hole gas (...

Embodiment 2

[0037] Such as Figure 5 As shown, the difference between this example and Example 1 is that the device rectification structure 9 of this example is a PN junction rectifier, and other structures are the same as those of Example 1. The rectifier structure and the P-type region of the junction semiconductor layer form a PN junction, which prevents the leakage current of the gate-2DHG-2DEG from being caused by a positive voltage on the gate, resulting in premature breakdown of the device.

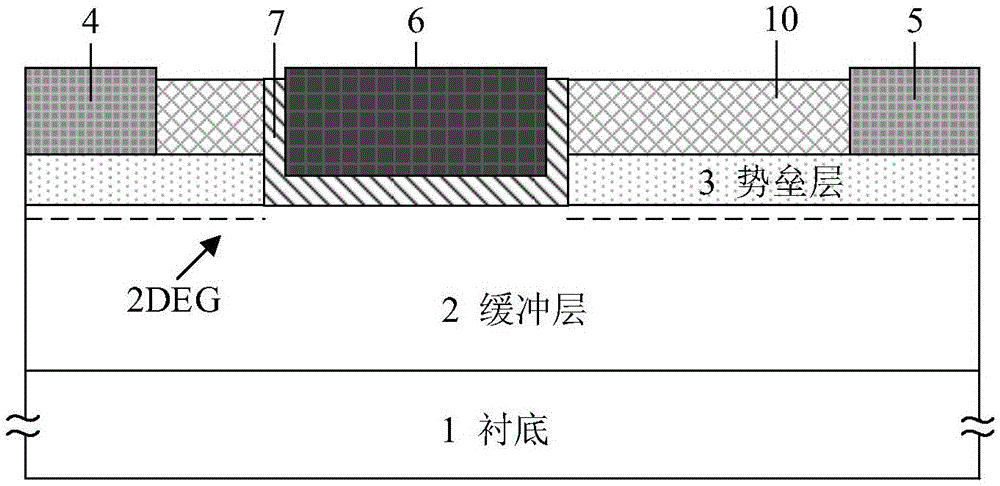

Embodiment 3

[0039] Such as Figure 6 As shown, the difference between this example and Example 1 is that the isolation layer 11 uses grooves to block 2DHG, which is used to avoid premature breakdown of the device caused by the leakage current of the gate-2DHG-2DEG when the gate is applied with a positive voltage. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com