Preparation method of honeycomb structure silicon-cobalt tetraoxide composite

A technology of tricobalt tetroxide and honeycomb structure, which is applied in cobalt oxide/cobalt hydroxide, structural parts, electrochemical generators, etc., and can solve problems such as structural stability and poor electrical conductivity, capacity fading, different structures and shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

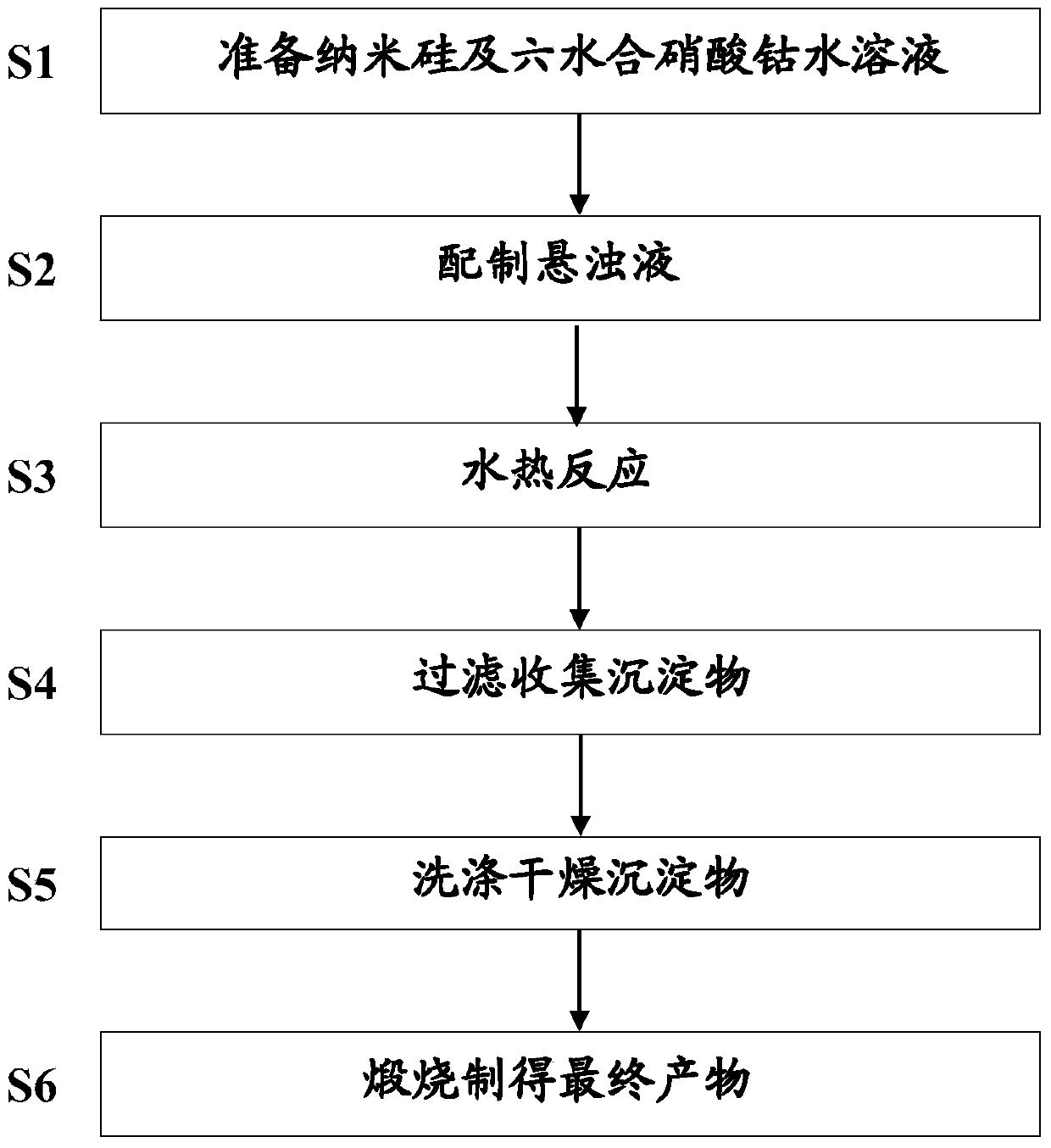

[0055] Please refer to figure 1 According to a non-limiting embodiment of the present invention, a method for preparing a honeycomb structure silicon-cobalt tetroxide composite is provided, and the method includes the following steps.

[0056] Prepare silicon with a particle diameter of about 30-50 nm and an aqueous solution of cobalt nitrate hexahydrate with a concentration of about 4 g / L.

[0057] Disperse the prepared silicon into the aqueous solution of cobalt nitrate hexahydrate at a mass ratio of about 1:5000, add urea as a precipitating agent, and add polyethylene glycol as a dispersant, wherein the mass of urea and cobalt nitrate hexahydrate aqueous solution The ratio is about 1:36, and the volume ratio of polyethylene glycol and cobalt nitrate hexahydrate aqueous solution is about 1:30; the prepared mixed solution is first ultrasonically treated in a cell pulverizer for about 30 minutes, and then subjected to constant temperature magnetic stirring , the stirring temper...

Embodiment 1

[0067] A kind of preparation method of honeycomb structure silicon-cobalt trioxide compound, such as figure 1 As shown, the following steps S1-S6 are included.

[0068] In step S1, silicon with a particle size of about 30-50 nanometers and an aqueous solution of cobalt nitrate hexahydrate are prepared, and the aqueous solution of cobalt nitrate hexahydrate is prepared by adding about 0.55 g of cobalt nitrate hexahydrate to about 150 ml of deionized water.

[0069] In step S2, about 0.03 grams of nano-silicon is dispersed in about 150 milliliters of cobalt nitrate hexahydrate aqueous solution with about 4 grams of urea as a precipitating agent, ultrasonicated in a cell pulverizer for 30 minutes, and then subjected to a constant temperature magnetic force at 40° C. Stirred for 10h to prepare a suspension.

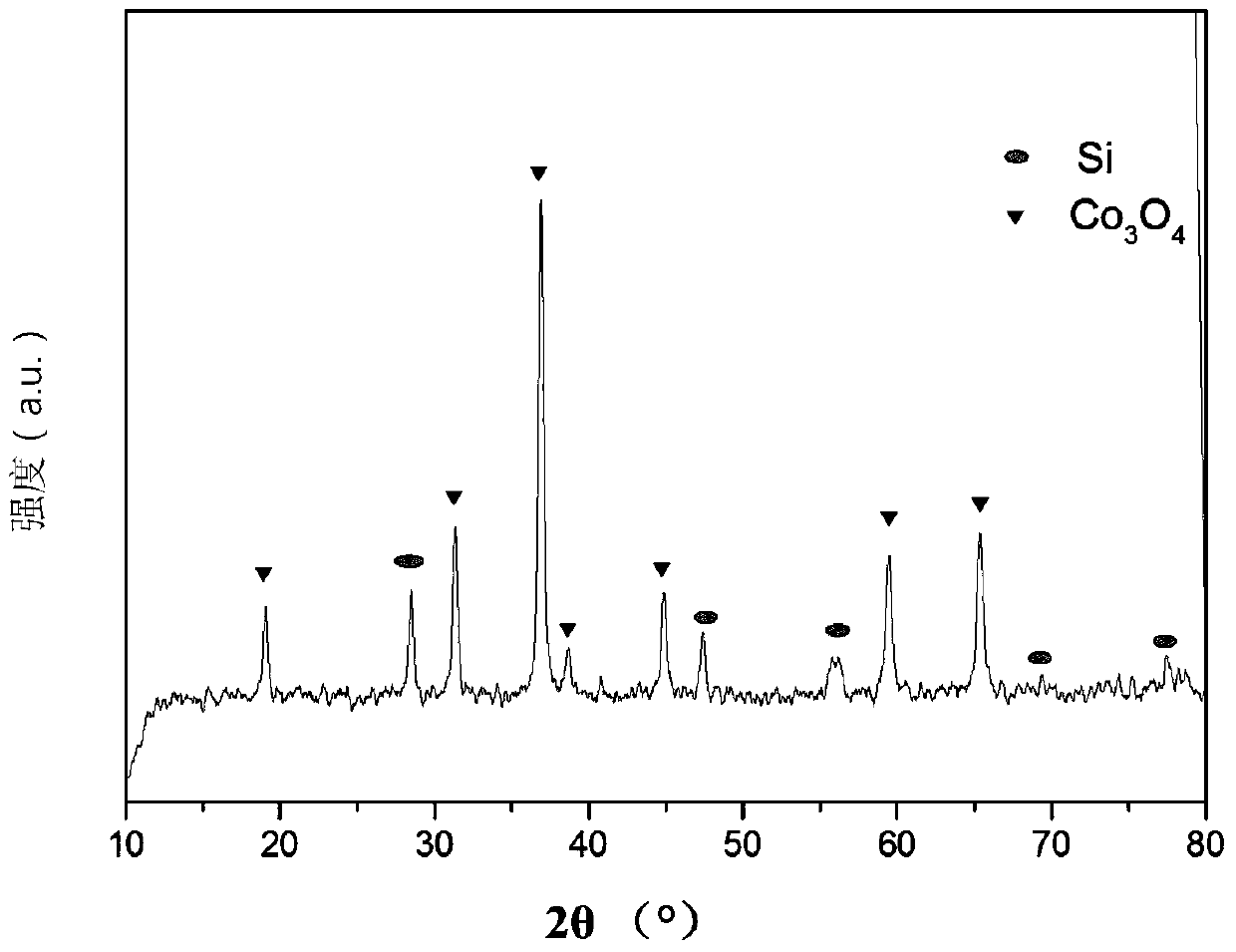

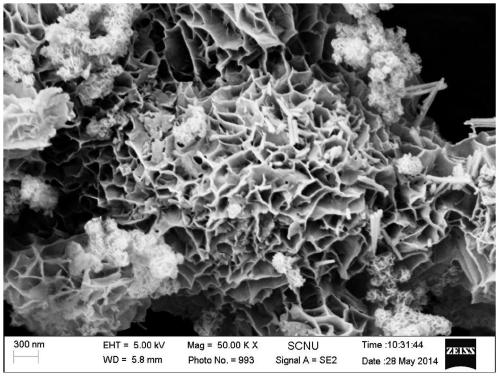

[0070] In step S3, hydrolysis conversion and self-assembly are carried out, the suspension obtained in step S2 is transferred to a stainless steel high-pressure hydrothermal...

Embodiment 2

[0076] Except that the constant temperature magnetic stirring temperature in step S2 is 45° C., other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com