Retaining structure-based heat transferring and dissipating system and wind generator set

A technology of enclosure structure and heat dissipation system, which is applied in the direction of wind turbine components, wind engines, wind power generation, etc., and can solve the problems of increasing the cost of racks and towers, increasing the load of racks, towers, and impacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

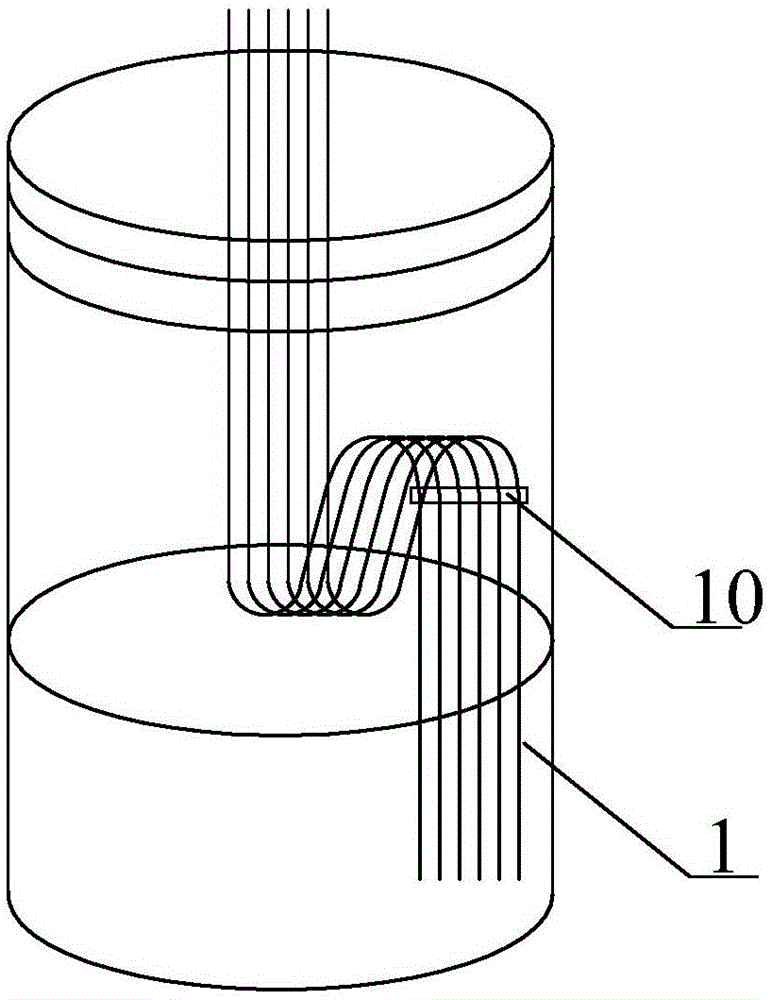

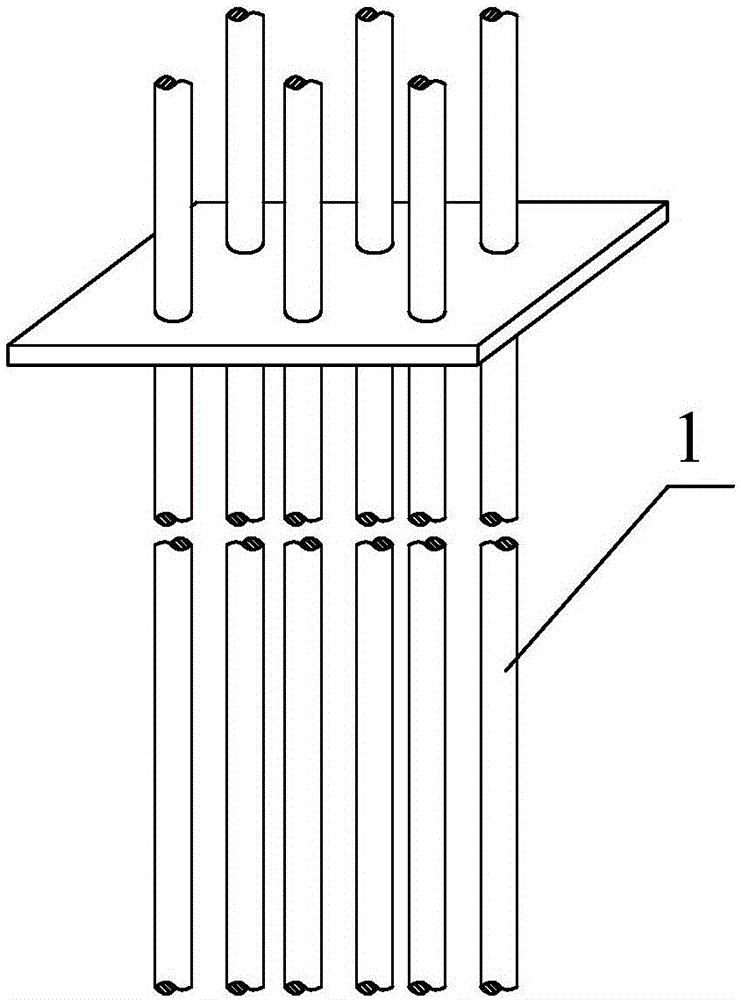

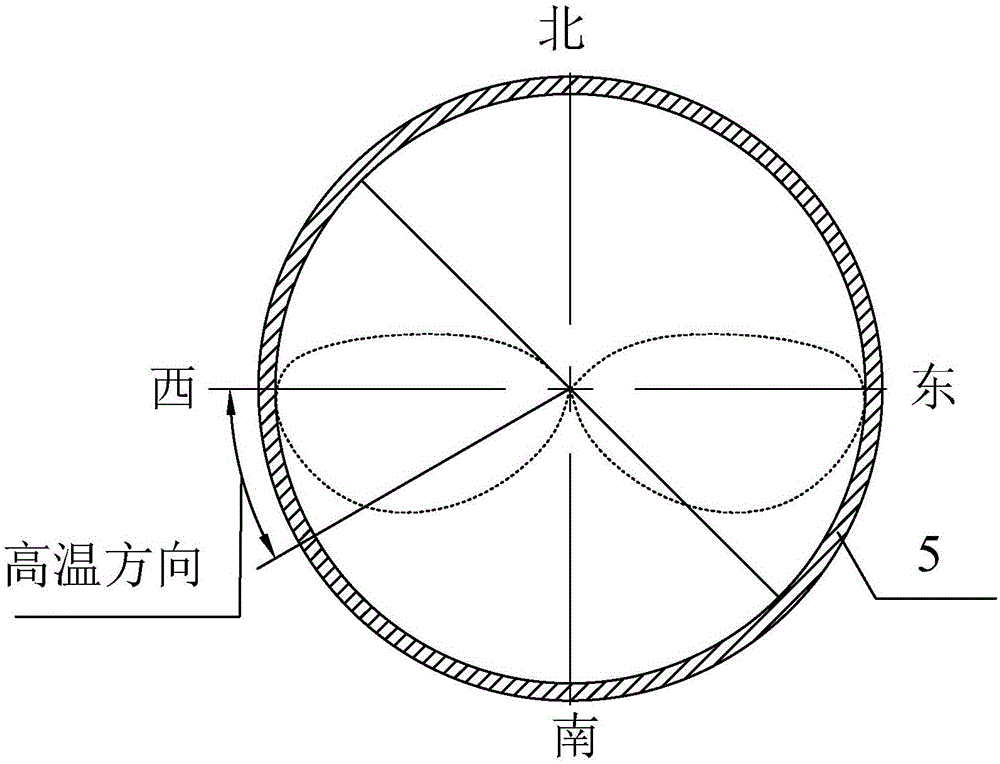

[0118] Such as Figure 6 to Figure 9 As shown, the heat transfer and cooling system based on the enclosure structure in this embodiment includes an enclosure structure and a power transmission cable 1 laid along the inner wall of the enclosure structure. The power transmission cable 1 is laid in a bent shape along the vertical direction. The power transmission cable 1 It is preferably laid in the region of the envelope close to the inner wall of the shade.

[0119] In the embodiment of the present invention, "bent shape" should be understood as the power transmission cable 1 is different from the prior art extending substantially linearly from top to bottom, but in a zigzag shape, a curved shape, or a combination of a zigzag line and a curve way, extending back and forth in the circumferential direction from top to bottom.

[0120] In this embodiment, the enclosure structure is a circular tower 5 with a horizontal section. In other embodiments, the enclosure structure can be ...

Embodiment 2

[0202] The heat transfer and cooling system of this embodiment is the same as the first embodiment in terms of its inventive concept, basic implementation, working principle and beneficial effects. For the sake of brevity, only the differences from the first embodiment are described here. Description of Embodiment 1.

[0203] The difference between this embodiment and the first embodiment lies in that the specific shape of the power transmission cable 1 bent along the vertical direction is different.

[0204] Such as Figure 17 As shown, in this embodiment, the power transmission cable 1 includes a plurality of twisted sections arranged from top to bottom in the vertical direction, and each twisted section includes two inclined subsections (ie, the first inclined subsection 11 and the second inclined subsection 11). Two inclined subsections 12) and the transition subsection 13 between the two inclined subsections, the angle between the first inclined subsection 11 and the sec...

Embodiment 3

[0208] The heat transfer and cooling system of this embodiment is the same as the first embodiment in terms of its inventive concept, basic implementation, working principle and beneficial effects. For the sake of brevity, only the differences from the first embodiment are described here. Description of Embodiment 1.

[0209] The difference between this embodiment and the first embodiment lies in that the specific shape of the power transmission cable 1 bent along the vertical direction is different.

[0210] Such as Figure 18 As shown, in this embodiment, the power transmission cable 1 also includes a plurality of twisted sections arranged from top to bottom in the vertical direction, and each twisted section includes two inclined subsections (ie, the first inclined subsection 11 and the first inclined subsection 11). The second inclined subsection 12) and the transition subsection 13 between the two inclined subsections, the angle between the first inclined subsection 11 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com