Oil tank-used series-type constant power electric tracing band

A series technology of electric heating cables, applied in the direction of heating element materials, heating element shapes, etc., can solve the problems of harsh operating environment of oil tanks and difficulty in applying electric heating cables, and achieve good mixing uniformity, enhanced mechanical properties and durability Corrosion performance, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

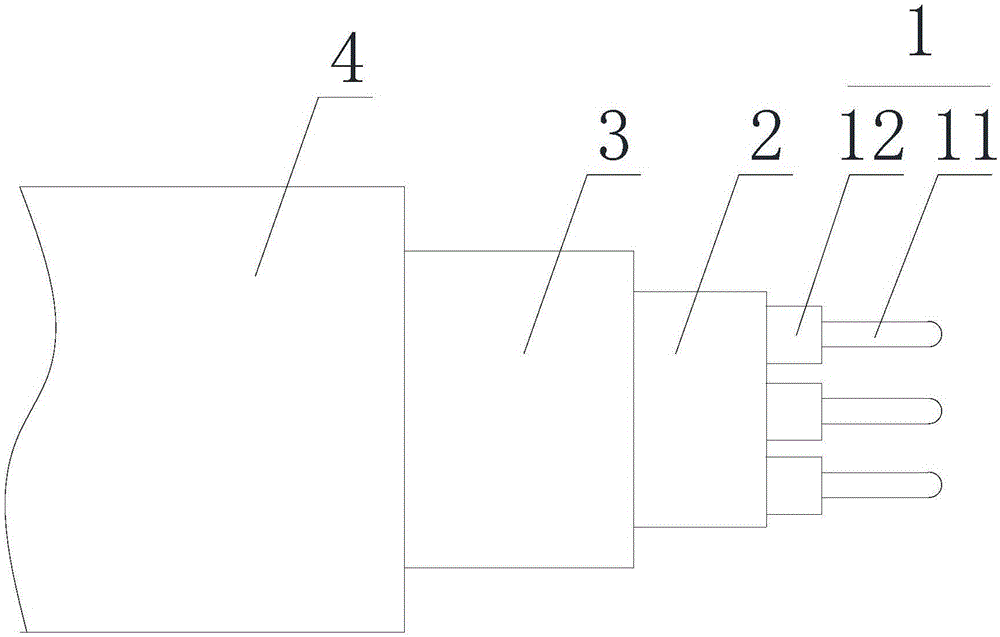

[0018] Reference figure 1 , A series-type constant power electric tracing cable for oil tanks, including heating components. The heating components are composed of three groups of heating units 1 arranged in parallel. Each group of heating units 1 consists of a heating core 11 and insulation covering the heating core 11 It consists of a layer 12, the heating component is covered with a sheath layer 2, the sheath layer 2 is covered with a metal braid layer 3, and the metal braid layer 3 is covered with a reinforcement layer 4; the reinforcement layer 4 is made of polypropylene .

[0019] The raw materials of the polypropylene material include 60 parts by weight of carboxyl nitrile rubber, 10 parts of EPDM, 40 parts of polypropylene, 0.5 part of dioctyl terephthalate, 3 parts of trioctyl phosphate, aromatic 1 part of hydrocarbon oil, 50 parts of white carbon black, 8 parts of clay powder, 18 parts of kaolin, 10 parts of modified gypsum, 20 parts of glass beads, 1 part of polyvinyl...

Embodiment 2

[0023] A series-type constant power electric tracing cable for oil tanks, including heating components, the heating components are composed of three groups of heating units 1 arranged in parallel, and each group of heating units 1 consists of a heating core 11 and an insulating layer covering the heating core 11 12 composition, the heating component is covered with a sheath layer 2, the sheath layer 2 is covered with a metal braid layer 3, and the metal braid layer 3 is covered with a reinforcement layer 4; the reinforcement layer 4 is made of polypropylene.

[0024] The raw materials of the polypropylene material include 40 parts by weight of carboxyl nitrile rubber, 20 parts of EPDM rubber, 30 parts of polypropylene, 1.5 parts of dioctyl terephthalate, 1 part of trioctyl phosphate, aromatic 2 parts of hydrocarbon oil, 40 parts of white carbon black, 13 parts of clay powder, 8 parts of kaolin, 20 parts of modified gypsum, 10 parts of glass beads, 3 parts of polyvinyl alcohol, 5 p...

Embodiment 3

[0028] A series-type constant power electric tracing cable for oil tanks, including heating components, the heating components are composed of three groups of heating units 1 arranged in parallel, and each group of heating units 1 consists of a heating core 11 and an insulating layer covering the heating core 11 12 composition, the heating component is covered with a sheath layer 2, the sheath layer 2 is covered with a metal braid layer 3, and the metal braid layer 3 is covered with a reinforcement layer 4; the reinforcement layer 4 is made of polypropylene.

[0029] 32 parts of polypropylene, 1 part of dioctyl terephthalate, 2 parts of trioctyl phosphate, 1.6 parts of aromatic hydrocarbon oil, 50 parts of white carbon black, 8 parts of clay powder, 18 parts of kaolin, 10 parts of modified gypsum, glass 20 parts of beads, 1 part of polyvinyl alcohol, 10 parts of polyvinyl butyral, 2 parts of liquid coumarone resin, antioxidant AT-2152 parts, stearic acid 1.4 parts, oleic acid 0.8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com