Desulfurization device

A desulfurization equipment and sulfur dioxide technology, applied in the field of sulfur desulfurization equipment, can solve the problems of low contact efficiency between flue gas and ammonia water or ammonia gas, difficulty in maintaining high-efficiency operation of desulfurization equipment, and low efficiency of spray equipment, so as to avoid regular shutdown and cleaning Scaling, improving dust removal efficiency, and saving ammonia water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

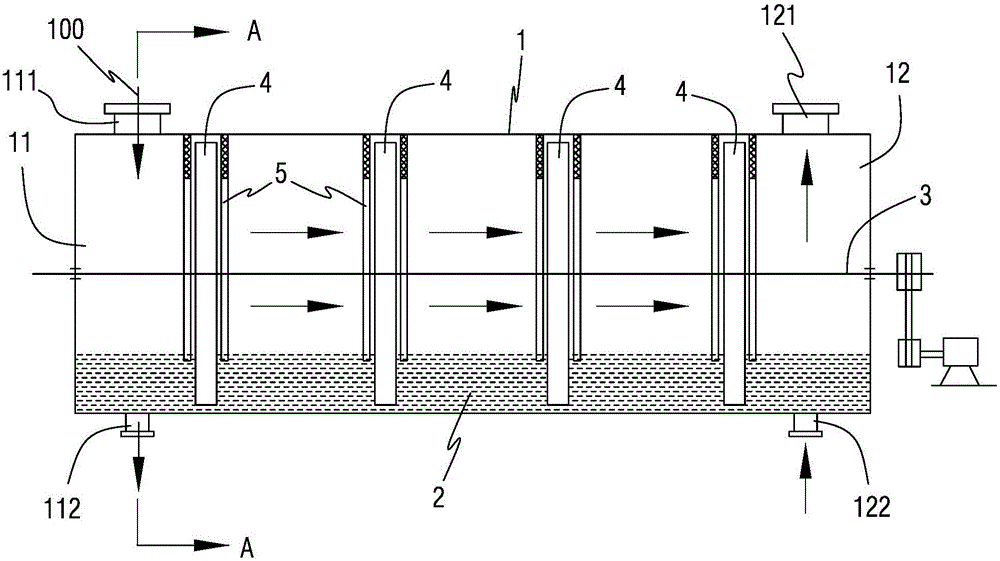

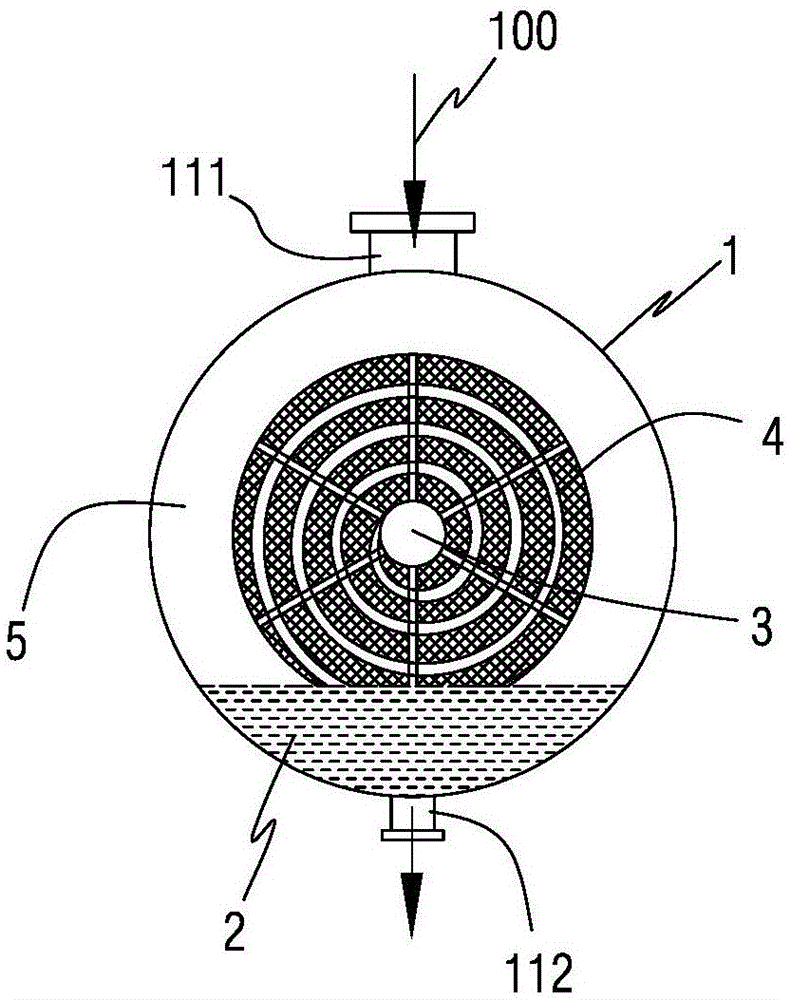

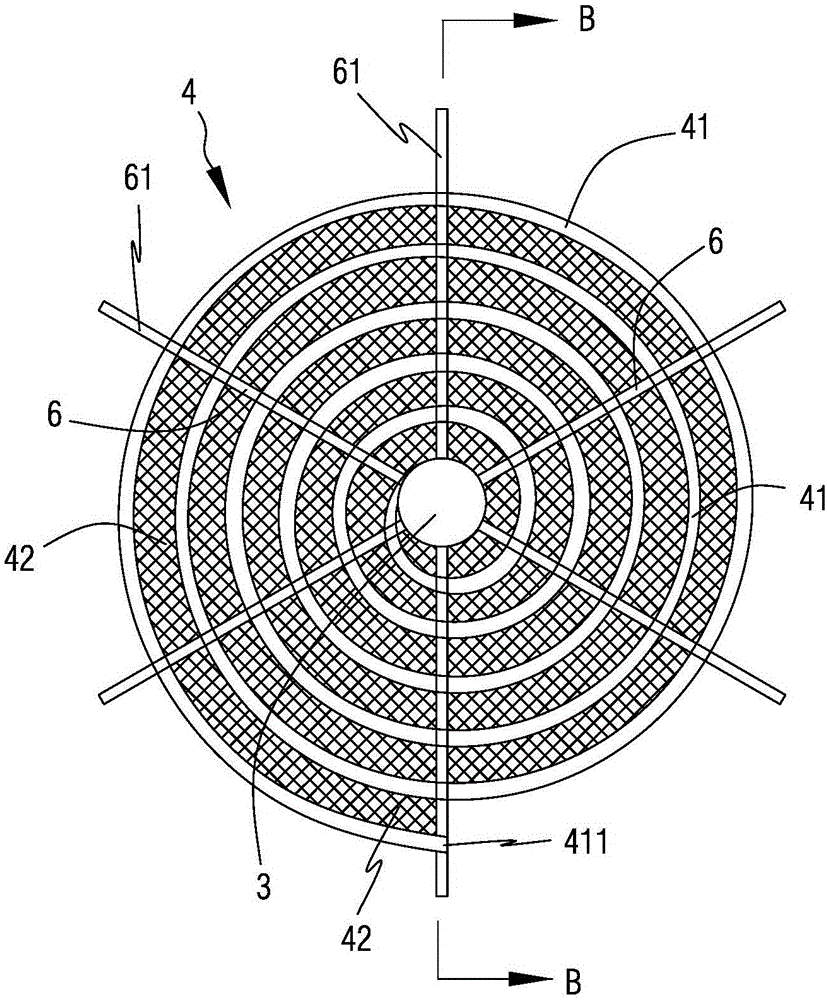

[0020] figure 1 Shown is a schematic structural view of a desulfurization device according to a specific embodiment of the present invention, figure 2 to show figure 1 A-A sectional view of desulfurization equipment shown, Figure 1-2 The desulfurization equipment shown in can be used for desulfurization, dust removal and purification treatment of coal-fired flue gas emissions from industries such as electric power, chemical industry, metallurgy, and manufacturing, and is especially suitable for removing sulfur dioxide and smoke in coal-fired flue gas 100.

[0021] As shown in the figure, the desulfurization equipment includes a horizontally arranged cylindrical housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com