Cobalt-based catalyst for direct conversion of syngas into low-carbon olefin and preparation method and application thereof

A technology of cobalt-based catalysts and low-carbon olefins, applied in physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high methane selectivity and low olefin selectivity and other problems, to achieve the effect of simple preparation method, easy industrial scale-up, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

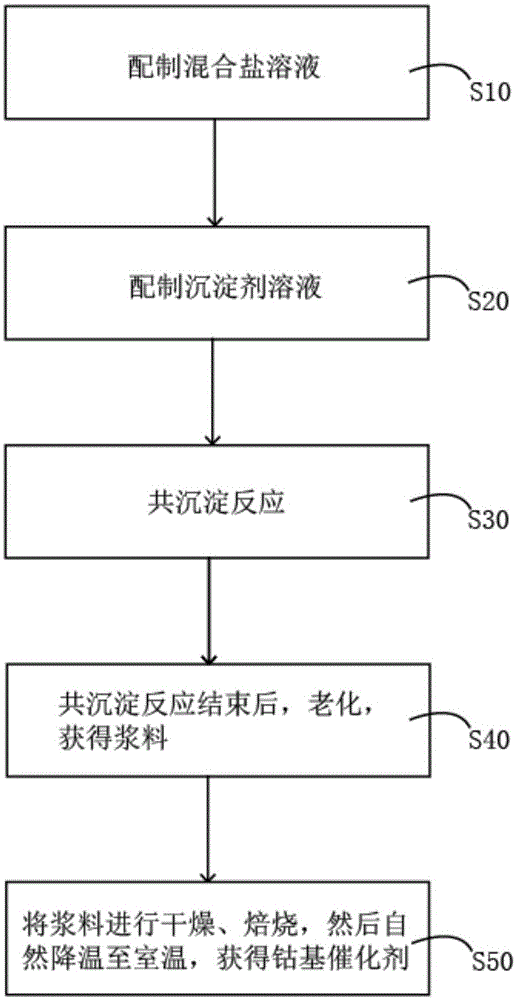

[0034] refer to figure 1 A method for preparing a cobalt-based catalyst for direct conversion of synthesis gas into light olefins provided by the invention, said preparation method comprising the following steps:

[0035] Step S10: preparing a mixed salt solution;

[0036] Step S20: preparing a precipitant solution;

[0037] Step S30: coprecipitation reaction;

[0038] Step S40: After the co-precipitation reaction is completed, aging to obtain the slurry;

[0039] Step S50: drying and calcining the slurry, and then naturally cooling down to room temperature to obtain a cobalt-based catalyst.

[0040] Specifically, the preparation method of the cobalt-based catalyst for the direct conversion of synthesis gas into light olefins provided by the present invention can be:

[0041] First, perform step S10: prepare mixed salt solution: when the catalyst does not contain additives, the inorganic salt of cobalt and manganese or the organic salt of cobalt and manganese are formulate...

Embodiment 1

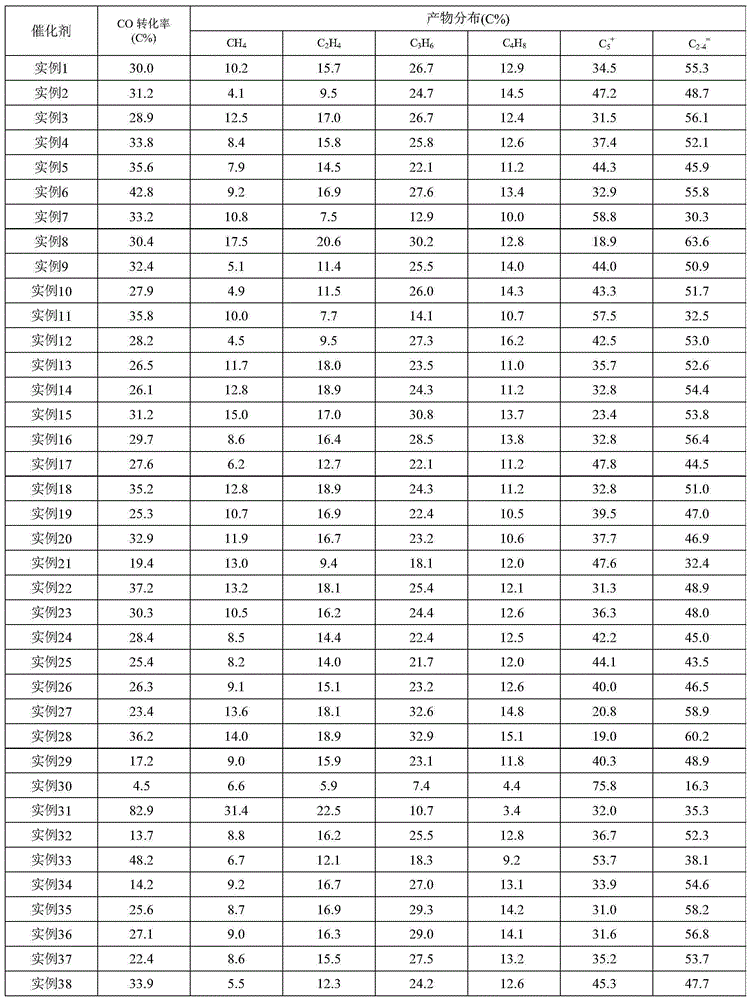

[0062] Cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and manganese nitrate (50%wtMn(NO 3 ) 2 , aq) be dissolved in deionized water as 1:2 by Co, Mn atomic ratio, the preparation becomes the mixed nitrate solution of Co, Mn that the total metal ion concentration is 2mol / L; Na 2 CO 3 dissolved in deionized water to prepare Na + Alkaline solution with a concentration of 2mol / L. Choose SiO2 2 As a carrier, use the co-precipitation method to make the two solutions undergo precipitation reaction, control the precipitation pH=8, the precipitation temperature is 50°C, and the precipitation time is 2 The catalyst was calcined under atmosphere for 10 h, and the temperature was naturally lowered to room temperature. 1.5ml of catalyst was loaded into a fixed bed for pre-reduction, and the reduction atmosphere was pure hydrogen at 400°C under normal pressure; after the reduction was completed, H 2 / CO is 2:1 for synthesis gas to react, the reaction temperature is 250°C, the reaction pressur...

Embodiment 2

[0064] Cobalt acetate (C 4 h 6 CoO 4 4H 2 O) and manganese nitrate (50%wtMn(NO 3 ) 2 , aq) be dissolved in deionized water as 1:2 by Co, Mn atomic ratio, prepare to become the mixed nitrate solution that total metal ion concentration is 1mol / LCo, Mn; Na 2 CO 3 dissolved in deionized water to prepare Na + Alkaline solution with a concentration of 1mol / L. Choose SiO2 2 As a carrier, use the co-precipitation method to make the two solutions undergo precipitation reaction, control the precipitation pH=8, the precipitation temperature is 50°C, and the precipitation time is 2 The catalyst was calcined under atmosphere for 10 h, and the temperature was naturally lowered to room temperature. 1.5ml of catalyst was loaded into a fixed bed for pre-reduction, and the reduction atmosphere was pure hydrogen at 400°C under normal pressure; after the reduction was completed, H 2 / CO is 2:1 for synthesis gas to react, the reaction temperature is 250°C, the reaction pressure is 0.5MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com