A kind of glutinous rice compound soil for pouring and preparation method thereof

A technology of compound clay and glutinous rice, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of difficulty in adapting to the construction of modern cultural relics protection projects, complex preparation process, large shrinkage, etc., to shorten the preparation time, The effect of simplifying the preparation process and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of glutinous rice compound

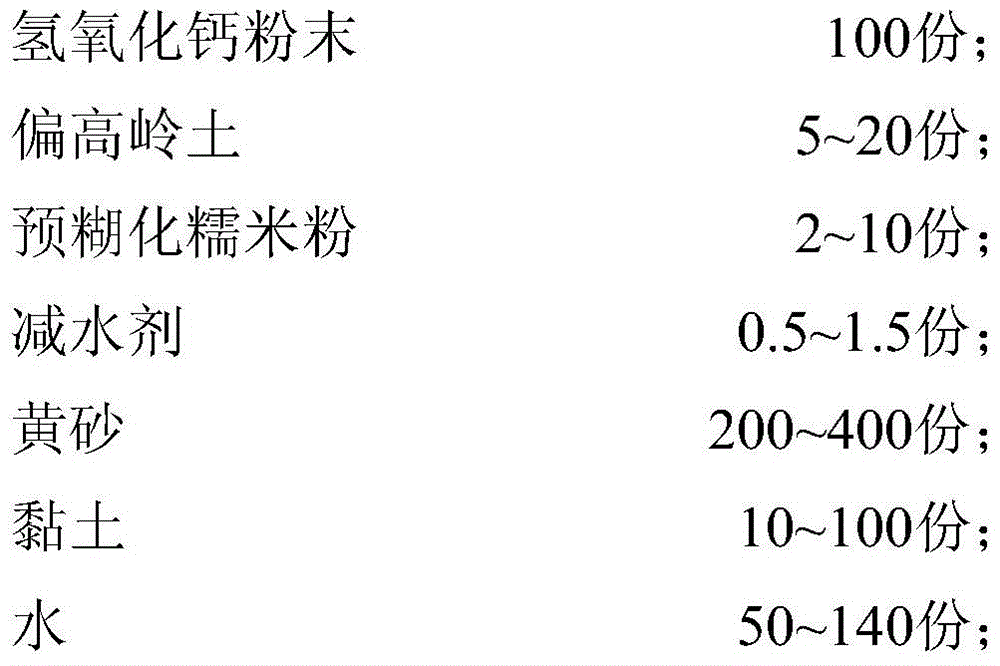

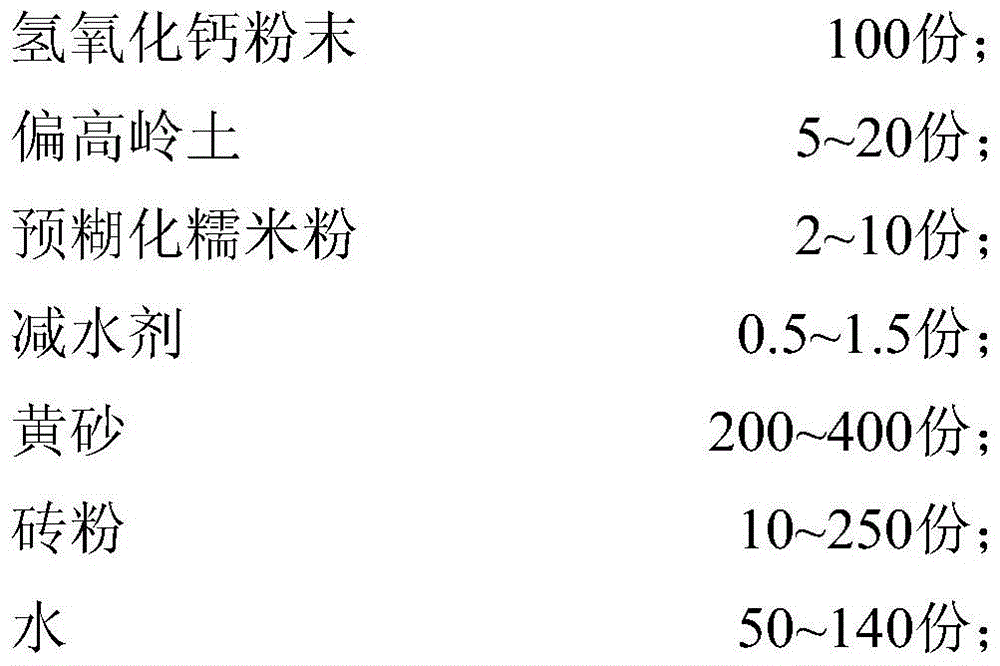

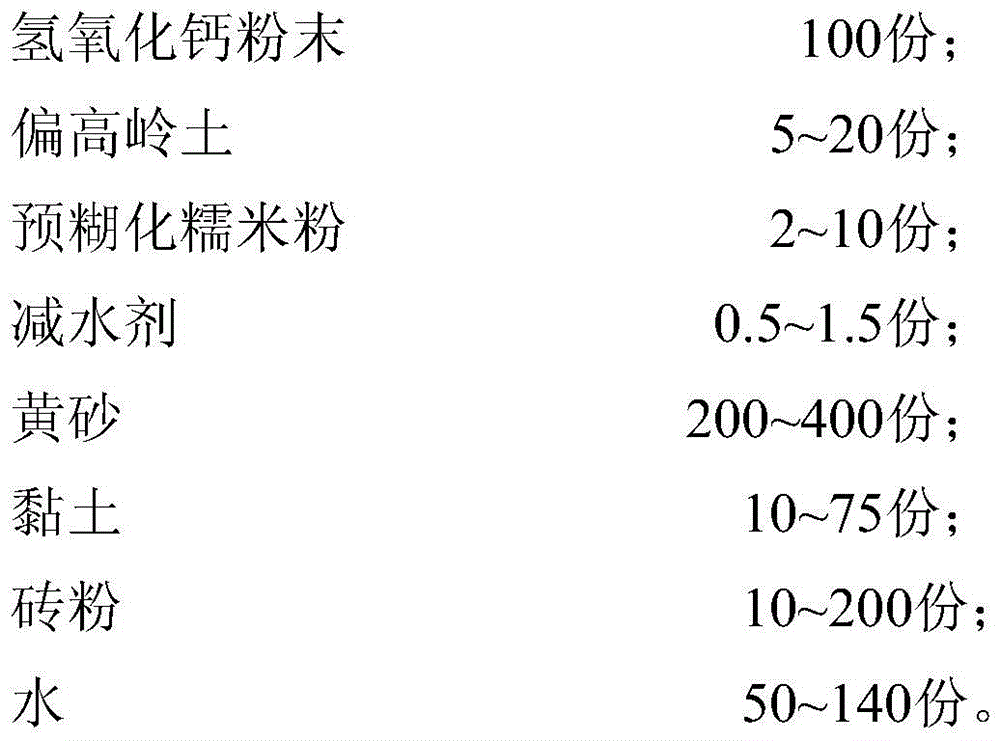

[0045] Weigh 100 parts with a purity of 95% and an apparent density of 0.72g / cm 3 , The specific surface area is 10.68m 2 / g of calcium hydroxide, 10 parts of metakaolin with pozzolanic activity, 5 parts of amylopectin content of 92%, apparent density of 0.17g / cm 3 Pre-gelatinized glutinous rice flour and 1 part of French Eisen C-SP polycarboxylate superplasticizer, mix the above raw materials as dry powder, stir at a speed of 500rpm for 5min, and store in sealed plastic bags;

[0046] Add 116 parts of the above-mentioned base material, add 300 parts of yellow sand with a particle size of 0.1-1mm, and 33 parts of clay passed through a 100-mesh sieve, first mix the dry material at a stirring speed of 500rpm for 5min, then add 75 parts of water, and then mix it at a speed of 1500rpm Stir for 8 minutes until the slurry is evenly mixed to obtain a glutinous rice compound slurry for pouring.

[0047] 2. Inspection of properties ...

Embodiment 2

[0052] 1. Preparation of glutinous rice compound

[0053] Weigh 100 parts with a purity of 95% and an apparent density of 0.72g / cm 3 , The specific surface area is 10.68m 2 / g of calcium hydroxide, 20 parts of metakaolin with pozzolanic activity, 10 parts of amylopectin content of 92%, apparent density of 0.17g / cm 3 The pre-gelatinized glutinous rice flour and 1 part of French Eisen C-SP polycarboxylate superplasticizer, the above raw materials are mixed as dry powder, stirred at a speed of 500rpm for 5min, and sealed in plastic bags for storage.

[0054] Add 131 parts of the above-mentioned base material, 200 parts of yellow sand with a particle size of 0.1 to 1 mm, 100 parts of clay passed through a 100-mesh sieve, and then add 90 parts of water, and stir at a speed of 1500 rpm for 8 minutes until the slurry is evenly mixed to obtain a concrete for pouring. Glutinous rice triad slurry.

[0055] 2. Inspection of properties of glutinous rice composite soil

[0056] Pour th...

Embodiment 3

[0060] Change the clay that crossed 100 mesh sieves into 50 parts in the raw material, and other steps are identical with embodiment 1.

[0061] The test results are as follows: the initial setting time is 17 hours, the shrinkage rate is 2.08%; the flexural strength at 28 days is 0.82MPa, and the compressive strength is 2.21MPa; with continued maintenance, the compressive strength at 3 months is 2.76MPa. The appearance of the test block is similar to that of traditional composite soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com