Environment-friendly flame-retardant type wood-plastic composite and preparation method thereof

A wood-plastic composite material, a flame-retardant technology, applied in the field of composite materials and its preparation, can solve the problems of burning, heat resistance, and flammability under fire or high temperature conditions, and is suitable for widespread use and good durability. Effect of Thermal Flame Retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

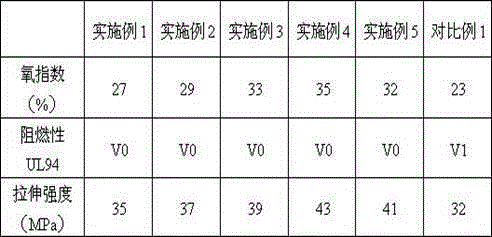

Examples

Embodiment 1

[0020] An environmentally friendly flame-retardant wood-plastic composite material, made of the following raw materials in parts by weight: 80 parts of wood flour, 20 parts of polystyrene, 20 parts of polyvinyl chloride, 10 parts of calcium silicate, 8 parts of aluminum oxide, phosphoric acid 5 parts of ammonium magnesium, 5 parts of 300 mesh water-based sepiolite, 7 parts of acrylic resin, 5 parts of alkenyl succinate copper, 2 parts of KH-550 silane coupling agent, 3 parts of toluene diisocyanate crosslinking agent and 4 parts of water share.

[0021] The preparation method for preparing the above-mentioned environmentally friendly flame-retardant wood-plastic composite material includes the following preparation steps:

[0022] (1) Weigh the raw materials according to the above parts by weight;

[0023] (2) Put the weighed polystyrene, polyvinyl chloride, calcium silicate, alumina, magnesium ammonium phosphate, sepiolite, acrylic resin, copper alkenyl succinate, silane cou...

Embodiment 2

[0027] An environmentally friendly flame-retardant wood-plastic composite material, made of the following raw materials in parts by weight: 200 parts of wood powder, 40 parts of polystyrene, 50 parts of polyvinyl chloride, 30 parts of calcium silicate, 25 parts of aluminum oxide, phosphoric acid 20 parts of ammonium magnesium, 18 parts of 300 mesh water-based sepiolite, 20 parts of acrylic resin, 16 parts of alkenyl succinate copper, 12 parts of Si-550 silane coupling agent, 15 parts of polyoxypropylene triol crosslinking agent and 12 parts of water.

[0028] The preparation method for preparing the above-mentioned environmentally friendly flame-retardant wood-plastic composite material includes the following preparation steps:

[0029] (1) Weigh the raw materials according to the above parts by weight;

[0030] (2) Put the weighed polystyrene, polyvinyl chloride, calcium silicate, alumina, magnesium ammonium phosphate, sepiolite, acrylic resin, copper alkenyl succinate, sila...

Embodiment 3

[0034] An environmentally friendly flame-retardant wood-plastic composite material, made of the following raw materials in parts by weight: 80-200 parts of wood powder, 20-40 parts of polystyrene, 20-50 parts of polyvinyl chloride, 10-30 parts of calcium silicate Parts, 8~25 parts of alumina, 5~20 parts of magnesium ammonium phosphate, 5~18 parts of 300 mesh water-based sepiolite, 7~20 parts of acrylic resin, 5~16 parts of alkenyl copper succinate, Si-550 2~12 parts of silane coupling agent, 3~15 parts of 1,6-hexamethylene diisocyanate crosslinking agent and 4~12 parts of water.

[0035] The preparation method for preparing the above-mentioned environmentally friendly flame-retardant wood-plastic composite material includes the following preparation steps:

[0036] (1) Weigh the raw materials according to the above parts by weight;

[0037] (2) Put the weighed polystyrene, polyvinyl chloride, calcium silicate, alumina, magnesium ammonium phosphate, sepiolite, acrylic resin, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com