Ultraviolet curing adhesive

A technology of adhesive and ultraviolet light, which is applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., and can solve the problem that high bond strength and good weather resistance cannot be achieved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

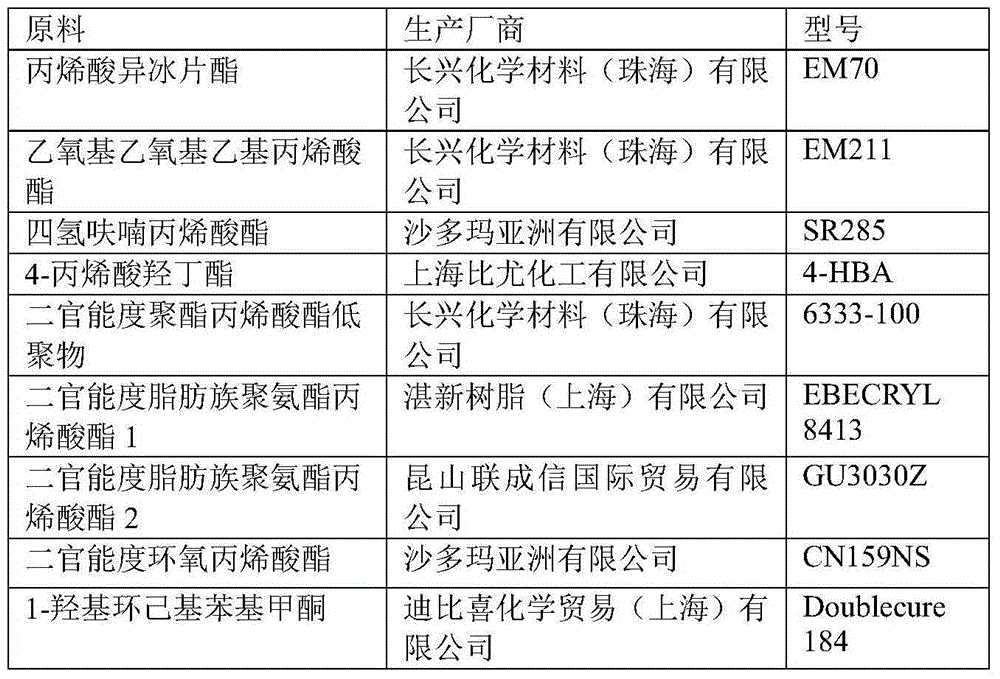

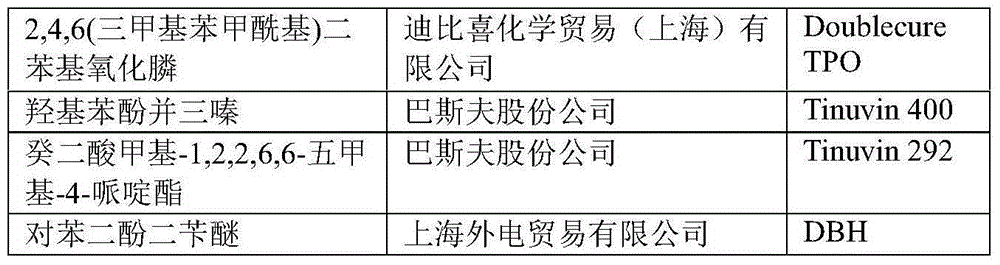

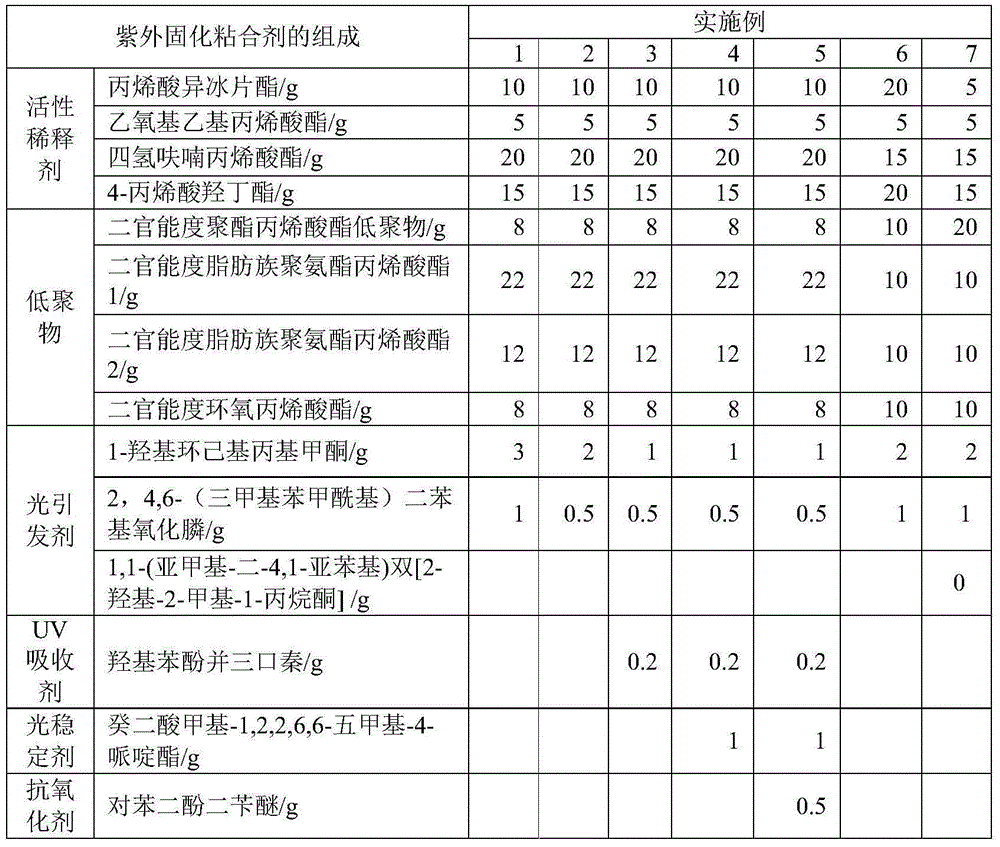

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. The present invention will be described in detail below in conjunction with embodiments.

[0023] As described in the background art, the existing problem exists that the bonding strength and weather resistance of the adhesive cannot be combined. In order to solve this problem, the present invention provides a UV-curable adhesive. In parts by weight, the adhesive includes 5-20 parts of polyester acrylate oligomer and 15-35 parts of urethane acrylate. , 5-20 parts of epoxy acrylate, 50-120 parts of reactive diluent and 1-3 parts of photoinitiator.

[0024] The above-mentioned adhesive provided by the present invention simultaneously contains three unsaturated oligomers of polyester acrylate oligomer, urethane acrylate and epoxy acrylate. Polyester acrylate oligomer has low viscosity and good compatibility with other componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com