All-nutrition rapid staple food grain and preparing method thereof

A full-nutritional and fast technology, applied in food preparation, food science, and vitamin-containing food ingredients, etc., can solve the problems of limited types of nutritional elements, unreachable, unsatisfactory nutrition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

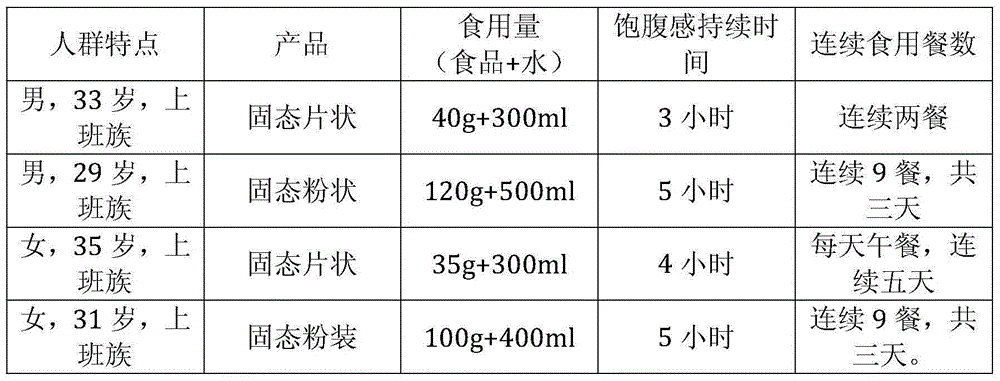

Examples

preparation example Construction

[0040] According to above-mentioned raw materials, the preparation method of fast staple food of whole nutrition is as follows, comprises the following steps:

[0041] Step 1. Weighing the raw materials in predetermined proportions by weight, and set aside;

[0042] Step 2, finely grinding the carbohydrates and cellulose in the raw materials until the particle size is greater than or equal to 100 mesh, and set aside;

[0043] Step 3, mixing and drying and sterilizing all raw materials to prepare semi-finished products;

[0044] Step 4. Carry out metal detection inspection on the semi-finished product. If the inspection is qualified, it will enter the next step. If the inspection fails, it will be eliminated;

[0045] Step 5, prepare the semi-finished product after step 4 into solid powder, solid sheet or liquid finished product.

[0046] Furthermore, in the above step five, the preparation method of preparing the semi-finished product into a solid sheet-like product or a liq...

Embodiment 1

[0054] Weigh the raw materials with predetermined ratio by weight, specifically: rice protein 5, whey protein 2, crystalline fructose 5, oat flour 20, linseed powder 5, psyllium seed 1, multivitamin 0.1 (per 100 grams meet Vitamins include vitamin A 0.2 mg, vitamin D 0.0004 mg, vitamin B 1 0.4 mg, B vitamins 2 0.4 mg, B vitamins 6 0.4 mg, B vitamins 12 0.2 mg, niacinamide 4 mg, vitamin E 3 mg, folic acid 0.1 mg, calcium pantothenate 0.8 mg, vitamin C 40 mg), multimineral 1 (per 100 g of multiminerals includes iron 3 mg, calcium 200 mg, magnesium 50 mg , phosphorus 200 mg, zinc 2 mg, taurine 20 mg, L-carnitine 200 mg), combination of pumpkin powder and sesame powder 1, food flavor 1, salt 1; The particle size is greater than or equal to 100 mesh; all raw materials are mixed, dried and sterilized to prepare semi-finished products; metal detection inspection is carried out on the semi-finished products, if the inspection is qualified, it will enter the next step, if the inspec...

Embodiment 2

[0056] Take the raw material of predetermined ratio weight part, be specifically: soybean protein 25, positive nitrogen protein 20, sucrose powder 30, rice starch 50, sunflower seed oil powder 25, konjac powder 30, multivitamin 0.5 (every 100 grams meet the requirement of vitamins including Vitamin A 0.8mg, Vitamin D 0.0016mg, Vitamin B 1 1.6 mg, B vitamins 2 1.6 mg, B vitamins 6 1.6 mg, B vitamins 12 0.8 mg, niacinamide 16 mg, vitamin E 12 mg, folic acid 0.3 mg, calcium pantothenate 3.2 mg, vitamin C 160 mg), complex mineral 4 (per 100 g of complex minerals includes iron 13 mg, calcium 800 mg, magnesium 200 mg , phosphorus 700 mg, zinc 8 mg, taurine 140 mg, L-carnitine 2000 mg), a combination of barley powder, sesame powder and walnut powder 10, food flavor 10, salt 3; grind rice starch and konjac powder to The particle size is greater than or equal to 100 mesh; all raw materials are mixed, dried and sterilized to prepare semi-finished products; metal detection inspection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com