Device of increasing adsorption bed thermal-circular gas desorption regeneration efficiency and method thereof

A technology of hot gas circulation and regeneration efficiency, which is applied in the fields of chemical industry and environmental protection. It can solve the problems of increasing the regeneration time of the system, the inability to apply it on a large scale, and the low condensation temperature, so as to improve the desorption efficiency, solve the problem of secondary water pollution, and effectively desorb attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

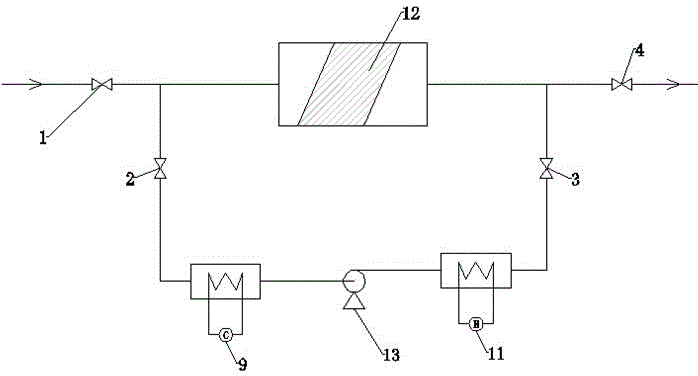

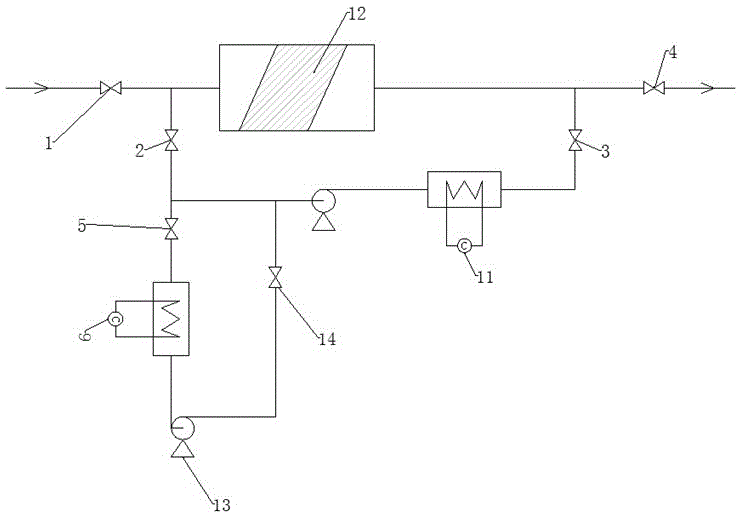

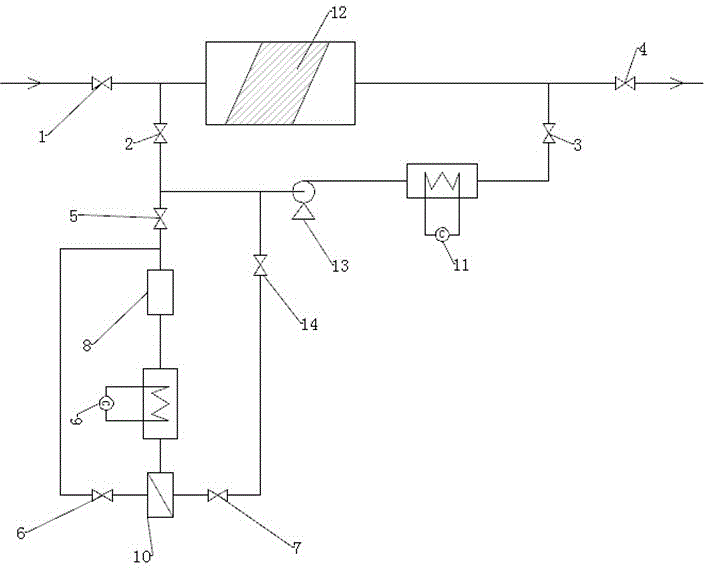

Embodiment 1

[0021] Embodiment 1: by the first valve 1, the second valve 2, the third valve 3, the fourth valve 4, the fifth valve 5, the sixth valve 6, the seventh valve 14, the pressure reducing valve 7, the air compressor 8, Condenser 9, membrane separation device 10, circulating gas heater 11, activated carbon bed 12, circulating fan 13, flow meter, temperature detector, corresponding pipelines and automatic control system are connected, the first valve 1, the fourth valve 4 and the activated carbon bed 12 constitute the adsorption gas path; the activated carbon bed 12, the circulating fan 13 and the circulating gas heater 11 constitute the desorption main gas path; the sixth valve 6, the seventh valve 14 and the air compressor 8, the condenser 9, and the membrane separation The device 10 and the pressure reducing valve 7 are connected to form a part of the condensation recovery gas path.

[0022] When the activated carbon bed is adsorbing, only the first valve 1 and the fourth valve 4...

Embodiment 2

[0024] Adopt the device described in embodiment 1 to be used for thermal cycle gas desorption recovery polyurethane solvent example

[0025] The drying room workshop of a certain coating production line has a system design scale of 5000m3 / h. Considering the heat preservation requirements of the drying room, the gas is recycled in a closed circuit without environmental discharge; the solvent is polyurethane paint solvent (including xylene, aromatic solvent ( Except xylene), butyl acetate and methyl isobutyl ketone, etc.); the temperature of the incoming gas is 50~80℃, and the content of organic matter in the gas is 400~3000mg / m 3 . The system adopts comprehensive energy utilization measures such as heat exchange, and the temperature of the return air is lower than the temperature of the incoming air by less than 10°C. The system is running normally, the purity of the solvent recovered from the polyurethane paint spraying process is greater than 99%, the water content of the so...

Embodiment 3

[0027] Using the device described in Example 1, a compound packaging factory, the system design scale air volume is 100,000 m 3 / h, the recovery solvent is ethyl acetate. The recovery of ethyl acetate by this method is 800 tons per year, the purity of the refined solvent is greater than 99.6%, and the water content is less than 300ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com