Chitosan-coated vitamin C micro-capsule and preparing method thereof

A vitamin and chitosan technology, applied in the chemical industry, can solve problems such as poor stability and low coating rate of vitamin C microcapsules, and achieve good application prospects, good biocompatibility and degradability, and prevent oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

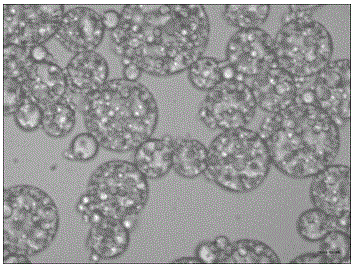

Image

Examples

Embodiment 1

[0028] A chitosan-coated vitamin C microcapsule, the parts by weight of each raw material are as follows:

[0029] 0.4 parts of vitamin C

[0030] 0.02 parts of anhydrous magnesium sulfate

[0031] 15.5 parts of soybean oil

[0032] Span 800.4 copies

[0033] 0.6 parts of glacial acetic acid

[0034] Chitosan 0.6 part

[0035] Tween 801.6 parts

[0036] Sodium tripolyphosphate 0.4 part

[0037] The balance is deionized water.

[0038] The preparation method of above-mentioned chitosan-coated vitamin C microcapsules comprises the following steps:

[0039] 1) Dissolve 0.4 parts of vitamin C in 3.16 parts of deionized water, add 0.02 parts of anhydrous magnesium sulfate, and sonicate until vitamin C is completely dissolved in water before use.

[0040] 2) Put the vitamin C aqueous solution obtained in step (1), 15.5 parts of soybean oil and 0.4 parts of Span 80 in a 100 mL three-necked flask, mechanically stir at 300 r / min for 1 hour, and homogenize for 4 minutes to obtai...

Embodiment 2

[0046] A chitosan-coated vitamin C microcapsule, the parts by weight of each raw material are as follows:

[0047] 2.5 parts of vitamin C

[0048] 0.04 parts of anhydrous magnesium sulfate

[0049] 27.0 parts of soybean oil

[0050] Span 800.6 copies

[0051] 1.2 parts of glacial acetic acid

[0052] Chitosan 1.0 parts

[0053] Tween 802.9 parts

[0054] Sodium alginate 0.6 parts

[0055] The balance is deionized water.

[0056] The preparation method of above-mentioned chitosan-coated vitamin C microcapsules comprises the following steps:

[0057] 1) Dissolve 2.5 parts of vitamin C in 10.88 parts of deionized water, add 0.04 parts of anhydrous magnesium sulfate, and sonicate until the vitamin C is completely dissolved in water before use.

[0058] 2) Put the vitamin C aqueous solution obtained in step (1), 27.0 parts of soybean oil and 0.6 part of Span 80 in a 100 mL three-neck flask, mechanically stir at 500 r / min for 2 hours, and homogenize for 6 minutes to obtain a...

Embodiment 3

[0064] A chitosan-coated vitamin C microcapsule, the parts by weight of each raw material are as follows:

[0065] 0.7 parts of vitamin C

[0066] 0.03 parts of anhydrous magnesium sulfate

[0067] 22.0 parts of soybean oil

[0068] Span 800.5 copies

[0069] 0.8 parts of glacial acetic acid

[0070] Chitosan 0.8 parts

[0071] Tween 801.8 parts

[0072] Calcium chloride 0.5 parts

[0073] The balance is deionized water.

[0074] The preparation method of above-mentioned chitosan-coated vitamin C microcapsules comprises the following steps:

[0075] 1) Dissolve 0.7 parts of vitamin C in 10.32 parts of deionized water, add 0.03 parts of anhydrous magnesium sulfate, and sonicate until the vitamin C is completely dissolved in water before use.

[0076] 2) Put the vitamin C aqueous solution obtained in step (1), 22.0 parts of soybean oil and 0.5 part of Span 80 into a 100 mL three-necked flask, mechanically stir at 400 r / min for 1.5 h, and homogenize for 5 minutes to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com