Highly active visible catalyst Ag / Cu2O hierarchy structural microsphere preparation method

A hierarchical structure, visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that the photocatalytic effect cannot be effectively improved, the method is cumbersome, The problem of uncontrollable material structure, etc., can improve the photocatalytic performance, the preparation process and process are simple, and the price and cost are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

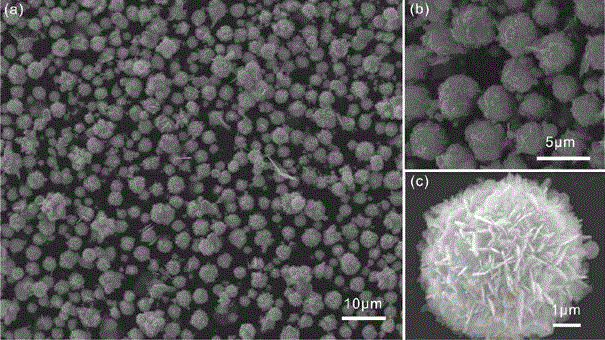

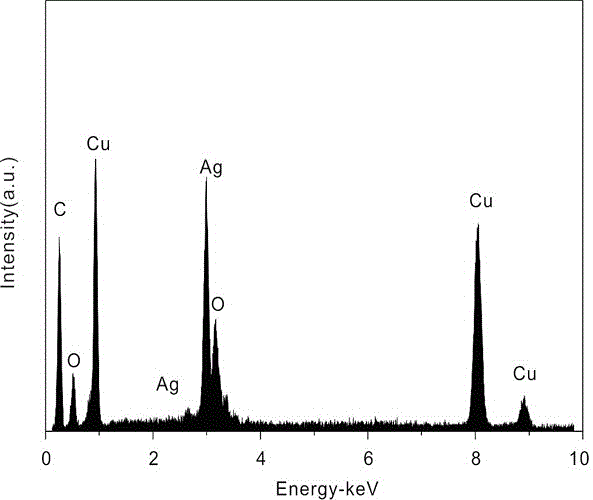

[0031] Highly Active Visible Light Catalyst Ag / Cu 2 O hierarchical structure microsphere preparation method, the method may further comprise the steps:

[0032] (1) Accurately weigh 0.3928g copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O), 0.0428g silver nitrate (AgNO 3- ) and 0.2g of polyvinylpyrrolidone (PVP), which were dispersed in a beaker containing 30mL of ethylene glycol, and fully dissolved under the action of magnetic stirring to form a clear and transparent blue solution.

[0033] (2) Transfer the above clear and transparent blue solution to a 40mL polytetrafluoroethylene-lined autoclave, heat at a constant temperature in an oven at 180°C for 1 hour, and cool to room temperature naturally after the reaction is complete.

[0034] (3) Take out the black precipitated product at the bottom of the polytetrafluoroethylene inner substrate, wash with deionized water and absolute ethanol three times each, to obtain a black solid powder.

[0035] (4) The above black solid...

Embodiment 2

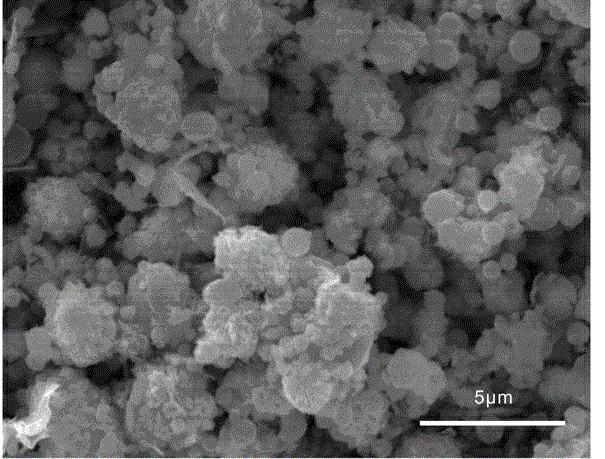

[0038] The difference from the preparation method in Example 1 is that the constant temperature heating time in an oven at 180° C. is changed to 2 hours and 3 hours respectively, and other conditions are the same as in Example 1. Such as Figure 4 and Figure 5 As shown, the reaction time is 2h and 3h, and microspheres with micro-nano hierarchical structure cannot be obtained. Such as Figure 6 and Figure 7 As shown, from the XRD analysis results of the obtained samples, it can be seen that the components in the two samples contain the phase of the Cu structure, indicating that in the preparation of Ag / Cu 2 In the process of micro-nano hierarchical structure microspheres, the material required by the application cannot be synthesized when the constant temperature heating time is 2h or more in an oven at 180°C.

Embodiment 3

[0040] The difference with the preparation method of Example 1 is that the silver nitrate AgNO is changed 3- Consumption is respectively 0.0639g and 0.0850g, and other conditions are identical with embodiment 1. Such as Figure 8 and Figure 9 As shown, when AgNO 3 Consumption is 0.0639g and 0.0850g, all can not obtain the micro-nano hierarchical structure microsphere with uniform appearance; Figure 10 and Figure 11 As shown, it can be seen from the XRD analysis results of the obtained sample that the components in the sample contain a Cu-structured phase. Explain that in the present invention in order to prepare Ag / Cu with uniform morphology 2 O micro-nano hierarchical structure microspheres, and the composition does not contain other impurities, the silver nitrate AgNO used 3- The dosage must be within the set value range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com