Universal durable anti-ultraviolet finishing agent for cotton and polyester and preparation method thereof

An anti-ultraviolet and finishing agent technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of limited application and poor convenience for printing and dyeing customers, and achieve the effect of wide range of raw materials, excellent washability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

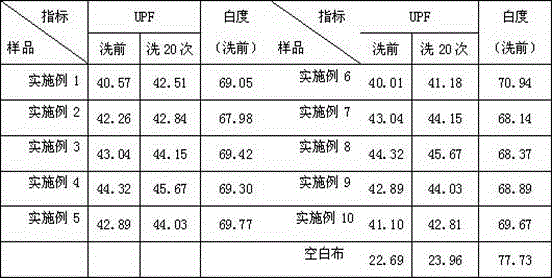

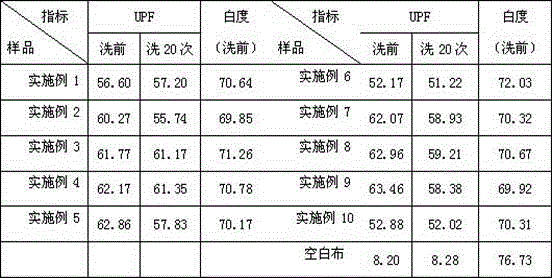

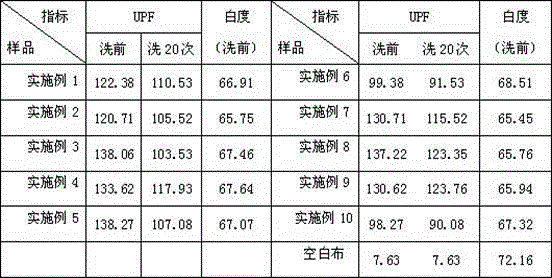

Examples

Embodiment 1

[0061] 1) Preparation of cationic silicone acrylic emulsion by emulsion polymerization

[0062] (1) Preparation of pre-emulsion: mix 7 g butyl acrylate, 18 g methyl methacrylate, 1.2 g vinyl triethoxy silane, 1.5 g vinyl-terminated silicone oil with a viscosity of 200 ± 30 cP, 1.5 g N-(isobutoxymethyl)acrylamide and 0.9 g and hydroxyethyl methacrylate are mutually dissolved as the oil phase; add 0.9 g 1227 and 2.4 g Pingping O-15, 0.5 g glacial acetic acid, and dissolve in 30 g. Ionized water is used as the water phase. Mix the water phase and the oil phase, quickly stir and pre-emulsify at room temperature, where the temperature does not exceed 40°C, the stirring speed is 1200 rpm, and the stirring time is 35 minutes.

[0063] (2) Prepare the primer: add 0.1 g 1227 and 0.9 g Pingping O-15 (23% of the total emulsifier mass), 0.125 g azobisisobuimidazoline hydrochloride and 40 g deionized water , Stir and dissolve evenly at room temperature. Put all the primers into a four-necked...

Embodiment 2

[0070] Step 1) According to Example 1, change the hard monomers to 6 g methyl methacrylate and 12 g styrene, and change the silicone to 1.5 g 3-methacryloxypropylmethyldimethoxysilane And 1.2 g of vinyl-terminated silicone oil with a viscosity of 300±20 cP, and change the corresponding cationic emulsifier in the pre-emulsion and primer to 1831;

[0071] Steps 2) and 3) are the same as in Example 1. The solid content of the finishing agent was measured to be 49.2%, and the pH value was 4.9.

Embodiment 3

[0073] Step 1) Same as Example 1;

[0074] Step 2) According to Example 1, change the ultraviolet absorbers used to 40 g EHA, 15 g UV-1130 and 30 gUV-531;

[0075] Step 3) Same as Example 1. The solid content of the finishing agent was 48.5% and the pH value was 5.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com