Blended composite material prepared from lactide surface grafted bamboo powder and polylactic acid, and preparation method and applications thereof

A technology of surface grafting and composite materials, which is applied to the composite materials obtained by high thermal decomposition temperature and stretching, can solve the problems of unsatisfactory physical properties, narrow application fields, complex processes, etc., and achieve biodegradable performance and wide application Prospects, effects of expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

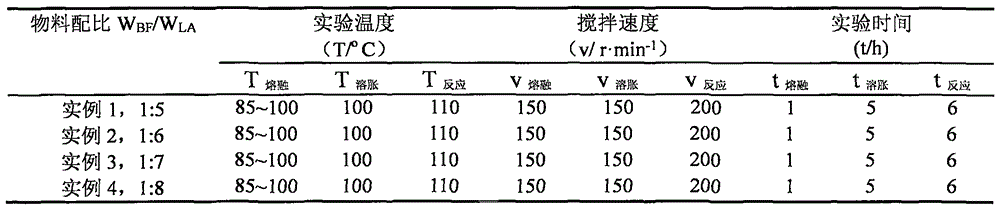

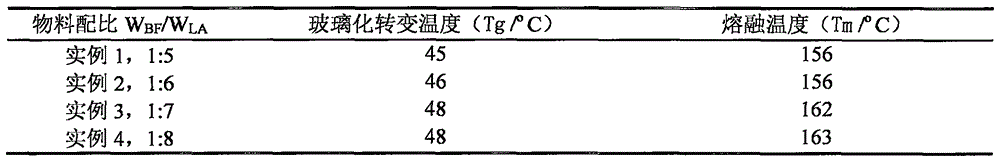

Embodiment 1~4

[0046] (1) the bamboo powder preparation of lactide surface grafting treatment in the embodiment

[0047] A. dry lactide (LA), bamboo powder (BA) in a desiccator, and control the moisture content below 0.05%;

[0048] B. Pour the lactide into the reactor, gradually raise the temperature to 100°C, start the agitator at the same time, gradually accelerate the stirring from low speed to a constant speed of 150r / min, until the lactide is completely melted;

[0049] C. Add the dried bamboo powder to the reactor, and at a stirring speed of 150r / min and a temperature of 100°C, the lactide liquid and the bamboo powder are fully and uniformly mixed, and the ratio of bamboo powder: lactide is 1: 5. 1:6, 1:7, 1:8;

[0050] D. Add the distilled and dried toluene solution containing 2% stannous octoate (accounting for lactide mass percentage). At the same time, increase the stirring speed to 200r / min, increase the temperature to 110°C, stop stirring after 1.5 hours of reaction, stop heat...

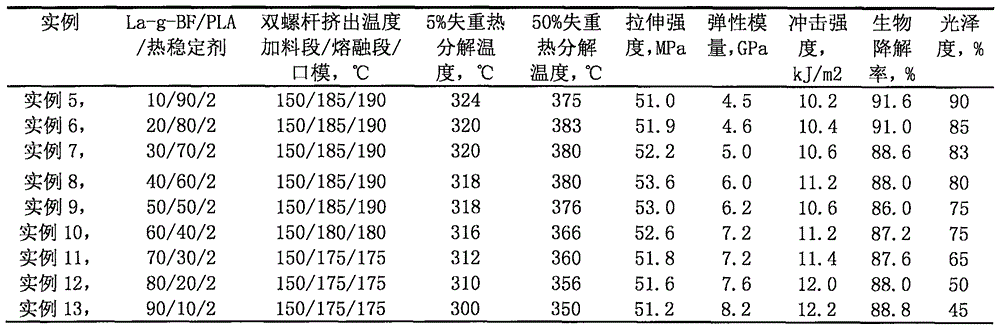

Embodiment 5-13

[0062] The lactide surface graft treatment bamboo powder and polylactic acid obtained in embodiment 2 are blended according to mass percentage to prepare composite material, and its preparation process is as follows:

[0063] (1) Pour the dried lactide surface-grafted bamboo powder and polylactic acid into equipment such as a high mixer according to a certain proportion, and add a certain amount of heat stabilizer, stir and mix;

[0064] (2) performing twin-screw extrusion granulation on the mixed mixture to obtain a biodegradable composite material;

[0065] The specific formulations and processing parameters of Examples 5-13 are shown in Table 3.

[0066] table 3

[0067]

example 14

[0069] The composite material granules obtained in Example 6 were then injection-molded by an injection machine. The temperatures in the three zones of the screw rod of the injection machine were 175°C, 180°C, and 185°C respectively to obtain cutlery and spoon products. Hygienic performance is tested according to GB / T5009.60, and the results meet the requirements of GB18006.1 on the hygienic physical and chemical indicators of other biodegradable disposable tableware.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com