Hydrophobic water-based fluorescent polyurethane paint and preparation method thereof

A technology of polyurethane coatings and polyurethanes, applied in the direction of polyurea/polyurethane coatings, luminous coatings, coatings, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The hydrophobic water-based fluorescent polyurethane coating of the present invention is prepared from the following raw materials according to the following weight ratio: 23% isophorone diisocyanate, 47% diol, 10% hydroxyl-terminated polysiloxane, organotin Catalyst 0.05%, hydrophilic chain extender 4%, end-capping agent 4.3%, triethylamine 3.7%, dodecafluoroheptyl methacrylate 8%, ammonium persulfate 0.4%, aziridine crosslinking agent 5%, Tellurium powder 0.008%, sodium borohydride 0.005%, chromium chloride hydrate 0.028%, mercaptopropionic acid 0.03%, and the rest is water.

[0050] Concrete preparation process is as follows:

[0051] (1) Add isophorone diisocyanate, polytetrahydrofuran ether glycol (Mn=2000), hydroxyl-terminated polysiloxane and tin catalysts into the reactor according to the above weight values, stir evenly with a mechanical stirrer, and then Raise the temperature to 80°C for 4 hours, then add dimethylolpropionic acid to the mixing system, heat to...

Embodiment 2

[0059] The preparation process of the hydrophobic water-based fluorescent polyurethane coating described in this embodiment is similar to that of Example 1, and the difference is: (1) the raw material proportioning in this embodiment is: 20% of isophorone diisocyanate, 50% of dibasic alcohol , hydroxyl-terminated polysiloxane 8%, organotin catalyst 0.04%, hydrophilic chain extender 3.5%, end-capping agent 4.5%, triethylamine 4%, dodecafluoroheptyl methacrylate 8%, persulfuric acid Ammonium 0.6%, aziridine crosslinking agent 3%, tellurium powder 0.009%, sodium borohydride 0.004%, chromium chloride hydrate 0.029%, mercaptopropionic acid 0.02%, and the rest is water. (2) The inorganic CdTe quantum dot phase is mixed with the obtained aqueous polyurethane phase according to the volume ratio of 2:1.

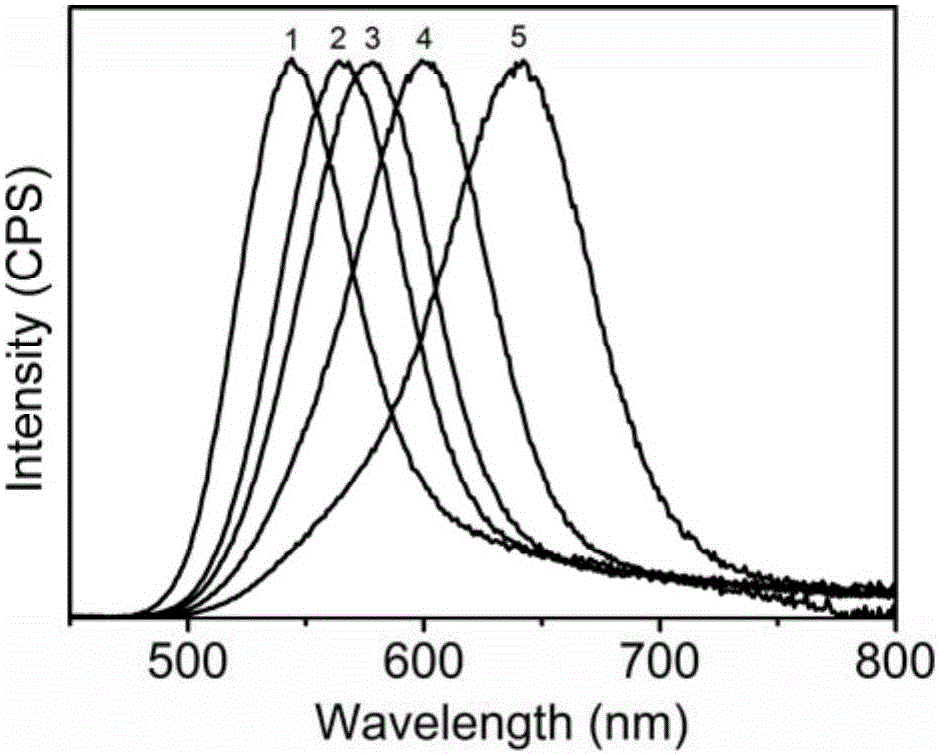

[0060] For performance characterization see figure 2 ,From figure 2 It can be seen that the water-based fluorescent polyurethane coating can still maintain a good fluorescent effe...

Embodiment 3

[0062] The preparation process of the hydrophobic water-based fluorescent polyurethane coating described in this embodiment is similar to that of Example 1, the difference is: (1) the raw material proportioning in this embodiment is: 23% of isophorone diisocyanate, 45% of dibasic alcohol , Hydroxyl-terminated polysiloxane 12%, organotin catalyst 0.06%, hydrophilic chain extender 3%, end-capping agent 3%, triethylamine 3.5%, dodecafluoroheptyl methacrylate 10%, persulfuric acid Ammonium 0.5%, aziridine crosslinking agent 2%, tellurium powder 0.006%, sodium borohydride 0.006%, chromium chloride hydrate 0.03%, mercaptopropionic acid 0.04%, and the rest is water. (2) The inorganic CdTe quantum dot phase is mixed with the obtained aqueous polyurethane phase according to the volume ratio of 3:1.

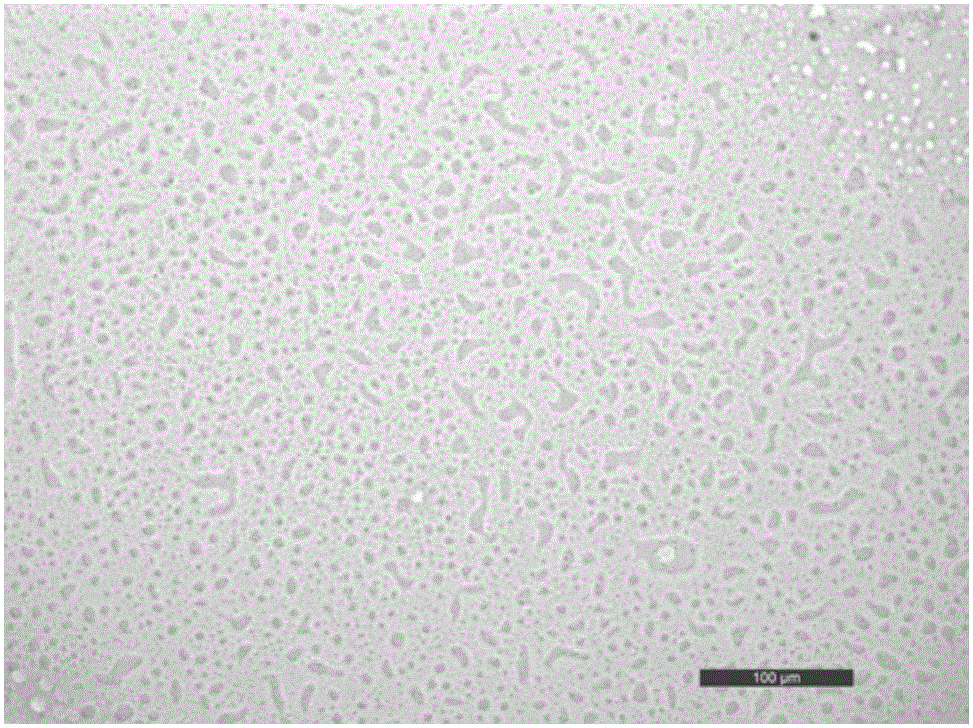

[0063] For performance testing see Figure 6 , by measuring the contact angle of hydrophobic fluorescent polyurethane paint with water, it is found that the contact angle is above 100°, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com