Method for preparing amoxicillin or ampicillin through full water phase

A technology of amoxicillin and ampicillin, applied in the direction of fermentation, etc., can solve the problems of environmental pollution, low environmental pollution, low production capacity, etc., and achieve the effects of simplified process steps, high activity coefficient, and strong adaptability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

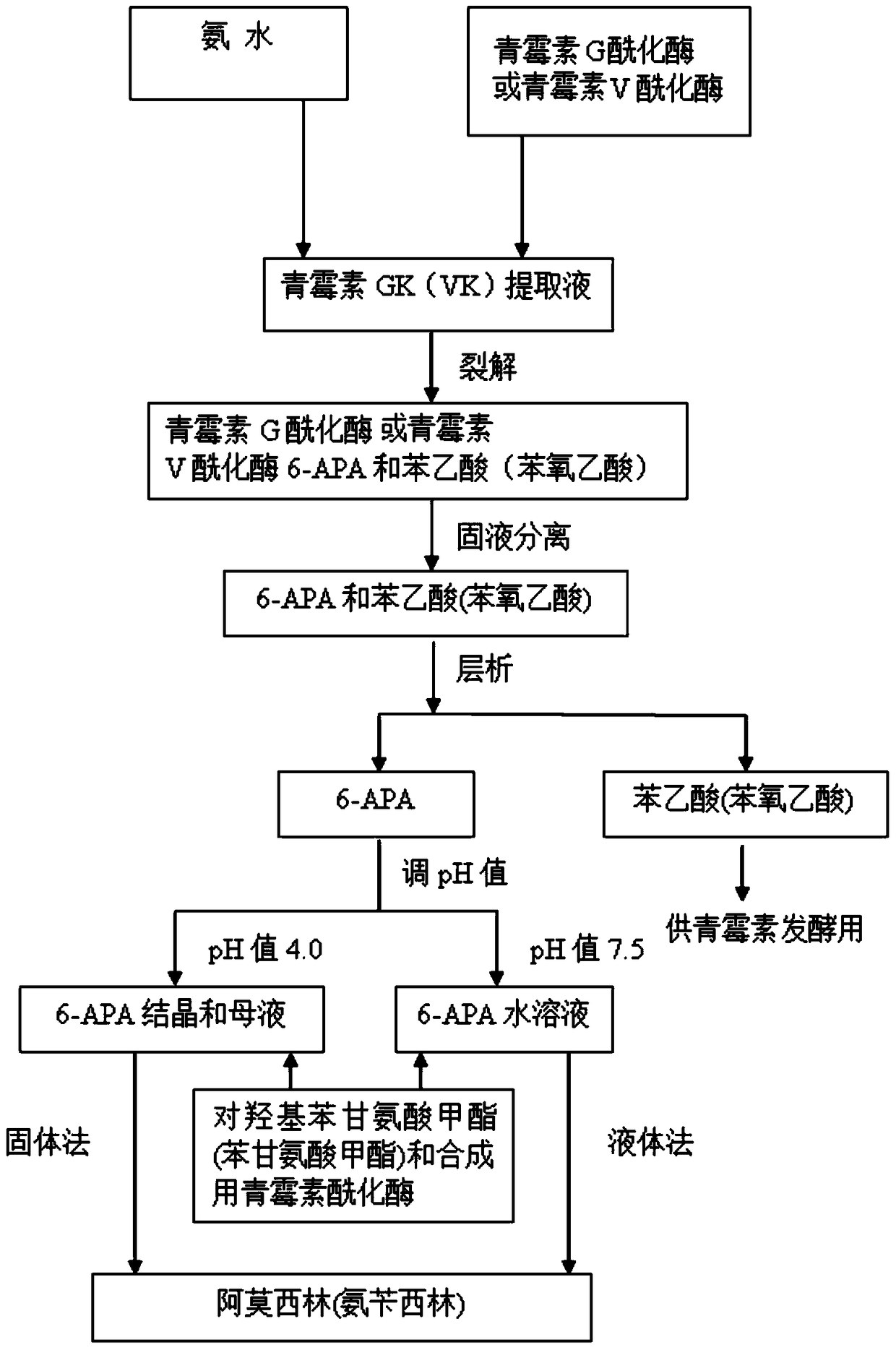

[0034] 1. Take 1000mL of 8%, 15%, 20%, 25% and 30% penicillin GK extract, according to 180U / g substrate, 200U / g substrate, 220U / g substrate, 240U / g substrate and 270U Put into immobilized penicillin G acylase (PGA-6) per g substrate, use 3N ammonia water to control the pH value of 8.0-8.3, temperature 30°C, cleavage time 1-2h, solid-liquid separation after cleavage, volume 1040mL-1200mL.

[0035] 2. Lower the temperature to below 10°C, lower the pH value to 0.5 with 6N hydrochloric acid, and remove the phenylacetic acid crystals by filtration to obtain 1200mL-1400mL 6-APA and phenylacetic acid mixed solution.

[0036] 3. Put 1200mL~1400mL 6-APA and phenylacetic acid mixture on the column (resin F-Z-001250mL), control the flow rate of the upper column to 1000mL / Hr, control the temperature below 10°C during the whole process, after the 6-APA and phenylacetic acid mixture is loaded on the column , wash the chromatography column with 250mL pure water, and then regenerate the chrom...

Embodiment 2

[0041] 1. Put 1000mL of 20% penicillin GK extract into immobilized penicillin G acylase (PGA-6) according to 220U / g substrate, control the pH value to 8.0-8.3 with 3N ammonia water, the temperature is 30°C, and the lysis time is 1-6hr , solid-liquid separation after lysis, volume 1100mL.

[0042] 2. Lower the temperature to below 10°C, lower the pH value to 0.5 with 6N hydrochloric acid, remove the phenylacetic acid crystals by filtration, and obtain 1300 mL of 6-APA and phenylacetic acid mixed solution.

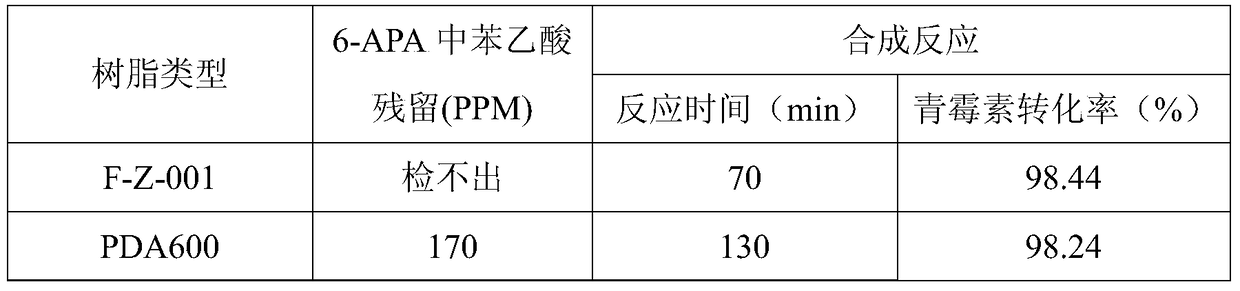

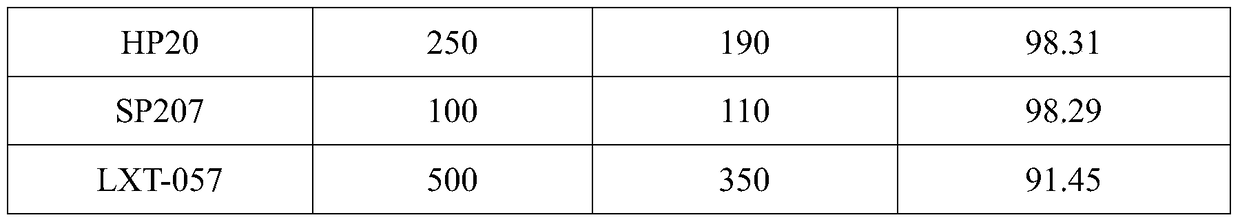

[0043] 3. 1300mL 6-APA and phenylacetic acid mixture, 250mL macroporous adsorption resin (F-Z-001, PDA600, HP20, SP207, LXT-057) on the column, control the flow rate of the upper column to 1000mL / Hr, and control the temperature below 10°C throughout the process , After the mixture of 6-APA and phenylacetic acid is applied to the column, wash the column with 250 mL of pure water, and then regenerate the column with 0.5 N sodium hydroxide. During the process, solutions with a...

Embodiment 3

[0050] 1. 1000mL of 20% penicillin GK&VK extract was put into immobilized penicillin G acylase (IPA-750) (Hunan Fulaige Biotechnology Co., Ltd.), immobilized penicillin G acylase (PGA- 6) and immobilized penicillin V acylase (PVA-4), use 3N ammonia water to control the pH value of 8.0-8.3 (PVA-4 controls the pH value of 7.0), the temperature is 30°C, the lysis time is 1-2hr, and the solid-liquid separation after lysis , volume 1100mL.

[0051] 2. Lower the temperature to below 10°C, lower the pH value to 0.5 with 6N hydrochloric acid, and remove phenylacetic acid or phenoxyacetic acid crystals by filtration to obtain 1300 mL of 6-APA and phenylacetic acid mixed solution or 6-APA and phenoxyacetic acid mixed solution.

[0052] 3. Put 1300mL of 6-APA and phenylacetic acid mixture or 6-APA and phenoxyacetic acid mixture on the column (resin F-Z-001250mL), and collect the solutions with 6-APA concentration greater than 5mg / mL respectively.

[0053] 4. Adjust the pH of the 6-APA c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com