A method for preparing machine-transplanted rice seedling-raising substrate by using decomposed corn stalks as raw material

A technology for raising decomposed corn stalks and rice seedlings, which is applied in the direction of planting substrates, botany equipment and methods, and culture media. It can solve the problems of nutrient soil consumption, large operating machinery load, difficult substrate degradation, and poor water retention, so as to reduce irrigation. The frequency and method are low cost and the effect of water retention is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of rice seedling-raising substrate by single bacterial agent fermentation + biocontrol bacteria

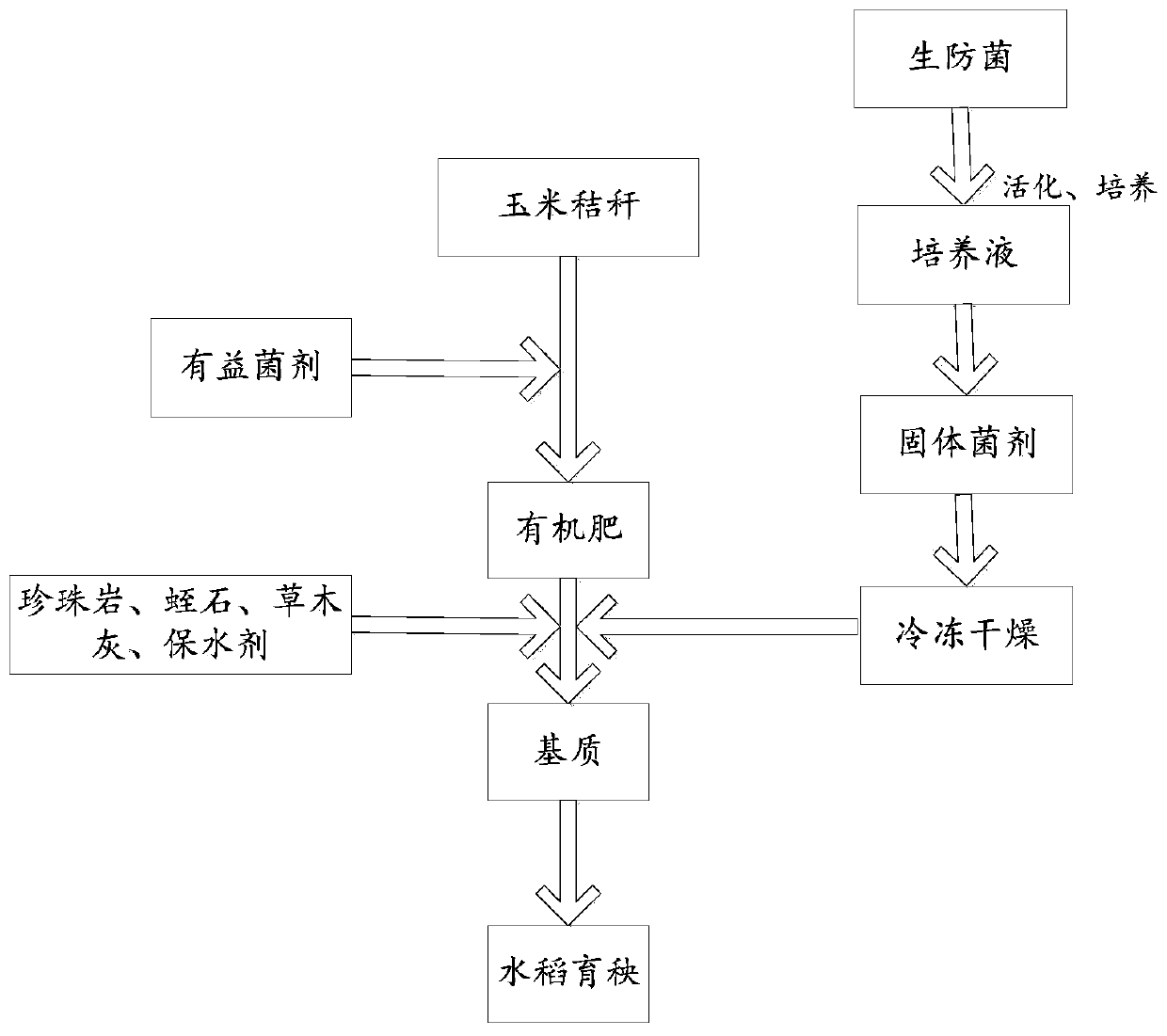

[0032] like figure 1 As shown, the organic fertilizer is prepared by fermenting the mixture of corn stalks and dry cow dung with beneficial bacteria, using organic fertilizer as the main material, adding auxiliary materials and activated solid biocontrol agents to prepare rice seedling raising substrate, the specific steps are as follows:

[0033] (1) Preparation of bacterial agents: Trichoderma viride and Bacillus subtilis are beneficial bacteria for aerobic fermentation. Trichoderma viride was cultured in potato glucose liquid medium at 180 rpm and 28°C for 5 days; Bacillus subtilis was cultured in beef extract peptone liquid medium at 180 rpm and 37°C for 2 days;

[0034](2) Composting of corn stalks and cow dung: Static aerobic high-temperature composting is carried out on the cement floor of the greenhouse, and 1000 kg of dry corn stalks are add...

Embodiment 2

[0052] Example 2: Preparation of rice seedling-raising matrix by three-component compound bacterial agent + biocontrol bacteria

[0053] In the following steps, unless otherwise specified, the same method as in Example 1 was used for processing.

[0054] Preparation of bacterial agents: Saccharomyces cerevisiae, Trichoderma viride, and Aspergillus niger were cultured in potato glucose liquid medium, 180 rpm, 28°C for 5 days; Bacillus subtilis was cultured in beef extract peptone liquid medium, 180 rpm, Incubate at 37°C for 2 days.

[0055] Corn stover and cow manure composting: two microbial treatment groups, Trichoderma viride + Aspergillus niger + Bacillus subtilis, Aspergillus niger + Bacillus subtilis )+Saccharomyces (Saccharomyces) group, the inoculum inoculation amount is 1.0%, 0.1% of the stacking mass successively, ferment according to the method described in Example 1, when the corn stalk and cow dung fermentation product temperature drops to ambient temperature, the...

Embodiment 3

[0073] Example 3: Fermenting corn stalks with six-component compound bacterial agents to prepare rice seedling-raising substrates

[0074] (1) Preparation of inoculum: two inoculum treatment groups are set up altogether, one group is the treatment group not inoculated with inoculum, and the other is the treatment group inoculated with liquid fermentation inoculum; the preparation and inoculation methods of liquid fermentation inoculum are : Saccharomyces cerevisiae, Trichoderma viride, and Aspergillus niger were cultured in potato glucose liquid medium at 180 rpm and 28°C for 5 days, and Acinetobacter, Bacillus subtilis, and Bacillus thuringiensis were cultured in beef extract peptone liquid medium at 180 rpm / min and cultured at 37°C for 2 days. Centrifuge the six kinds of bacterial solutions at 5000 rpm, remove the supernatant, wash the bacterial cells three times with a phosphate buffer solution with a pH of 7, and then suspend the bacterial cells with 1 liter of phosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com