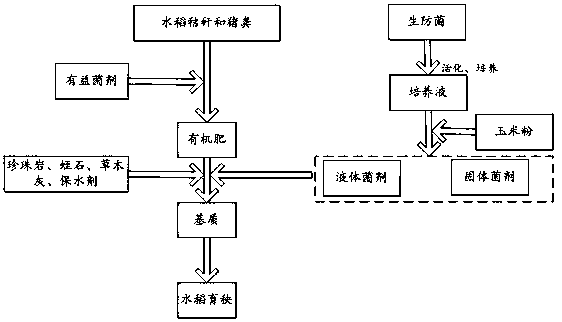

A kind of preparation method of machine-transplanted rice seedling raising substrate

A seedling-raising substrate and machine-transplanted rice technology, which is applied in the field of rice seedling raising and agricultural waste utilization, can solve the problems of large amount of nutrient soil and operating machinery load, difficult degradation of the substrate, poor water retention, etc., and achieve reduced irrigation times and good water retention , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of Phomopsis HQ285146 Biocontrol Agent

[0031] (1) Grind the sun-dried corn with a pulverizer and pass it through a 20-mesh sieve. Mix the obtained corn flour with phosphate buffer at a mass ratio of 1~2, stir at room temperature for 180 minutes, and let stand for 2 days. Collect solid-phase corn flour and corn flour extract for later use.

[0032] (2) The biocontrol bacterium Phomopsis HQ285146 was activated and cultivated on the potato glucose slope for 3 days, inoculated into the potato glucose liquid medium and cultured for 4 days to obtain the seed liquid, and then the seed liquid was cultured at a volume ratio of 1% for 6 days to obtain the cultured liquid, spare.

[0033] (3) Mix the culture solution of step (2) with the extract of corn flour at a volume ratio of 1:9 to obtain a liquid biocontrol agent with a viable count of 10 billion / ml; mix the culture solution of step (2) with corn flour According to the mass ratio of 1:5, the solid b...

Embodiment 2

[0035]Static aerobic high-temperature composting is carried out on the cement floor of the greenhouse. In this embodiment, two experimental groups are set up, one group is added with probiotics, and the other group is not added with probiotics. Add fermented probiotics to 1000 kg of rice straw with a length of 3 cm. The fermented probiotics are composite bacteria of Aspergillus niger and Saccharomyces cerevisiae. The volume ratio of each component of the composite bacteria is 1:1. %, use fresh pig manure with a moisture content of 80% to adjust the C / N of the compost material to 27, and adjust the moisture content to 70% at the same time, stack the material into a stack with a height of 1.5m and a diameter of 2m, and carry out aerobic high temperature for 50 days For fermentation, turn the compost every 2 days in the first 30 days of composting, and add an appropriate amount of water to maintain sufficient moisture content, and turn the compost every other week in the later sta...

Embodiment 3

[0038] Static aerobic high-temperature composting was carried out on the cement floor of the greenhouse. Add fermented probiotics to 1500 kg of peanut straw with a length of 4 cm. Trichoderma viride is selected as the fermented probiotics. The inoculation amount of the probiotics is 0.6% of the stacking weight. The C / N of the compost material is adjusted to 27 with chicken manure. The moisture content is 65%, and the piles are stacked into piles with a height of 2m and a diameter of 3m, and aerobic high-temperature fermentation is carried out for 40 days. The pile is turned every 2 days for the first 30 days of composting, and an appropriate amount of water is added to maintain sufficient moisture. Moisture content, in the later stage of composting, turn the compost once every other week, and mix the materials evenly. When the temperature of the peanut straw and chicken manure fermented product drops to the ambient temperature, and the color is brown and has no odor, the stack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com